Seed crystal splicing structure suitable for directional solidification ingot casting

A technology of directional solidification and seed crystal, which is applied in the field of silicon crystal manufacturing, can solve problems affecting the quality of single crystal ingots, poor process tolerance performance, seed crystal splicing deformation, etc., to improve photoelectric conversion efficiency and increase single crystal area Scale, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

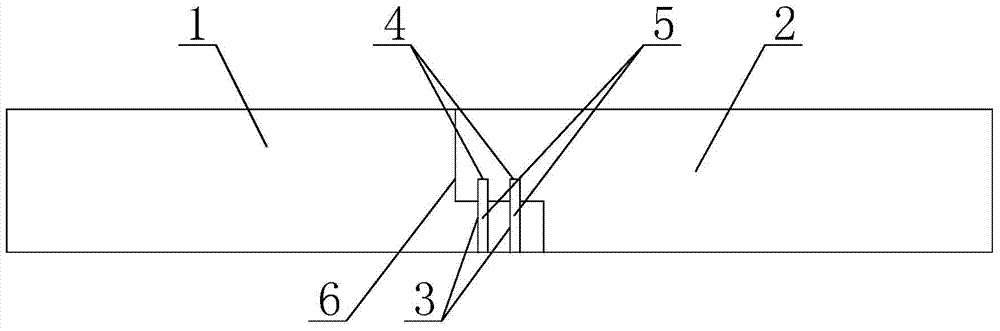

[0020] Such as figure 1 , figure 2 As shown, the embodiment of the present invention is suitable for the seed crystal splicing structure of the directionally solidified ingot, including the seed crystal blocks 1 and 2 that are spliced with each other. The seed crystal block is a plate seed crystal, or a block seed crystal or a square seed crystal. . The seed crystal block 1 has an L-shaped structure at the joint, and the seed crystal block 2 has an inverted L-shaped structure at the joint, so that the joint surface 6 of the two presents a stepped shape that is interlocked with each other, and the seed crystal blocks 1 and 2 are buckled. Two pairs of matching cylindrical holes 3 and 4 are provided at the center of the crucible. The cylindrical holes 3 and 4 are perpendicular to the bottom of the crucible. The aperture range of the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com