Method and device for growing high-purity semi-insulating silicon carbide single crystal

A silicon carbide single crystal, semi-insulating technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of low solubility, high difficulty, reduced N content, high-purity semi-insulating SiC, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

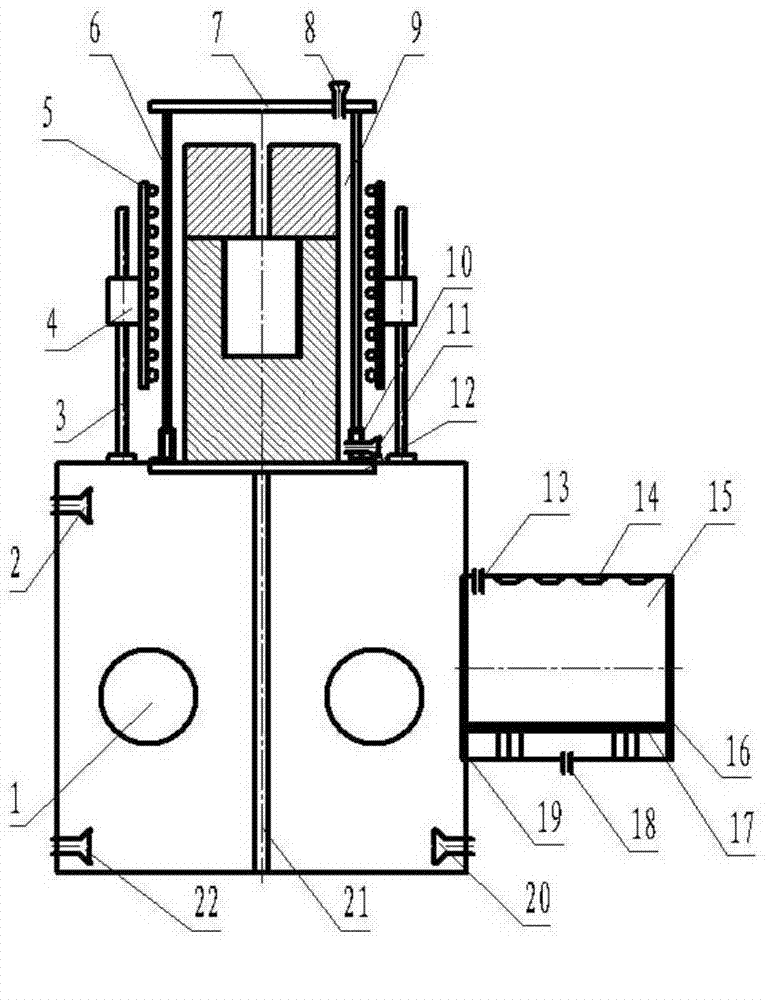

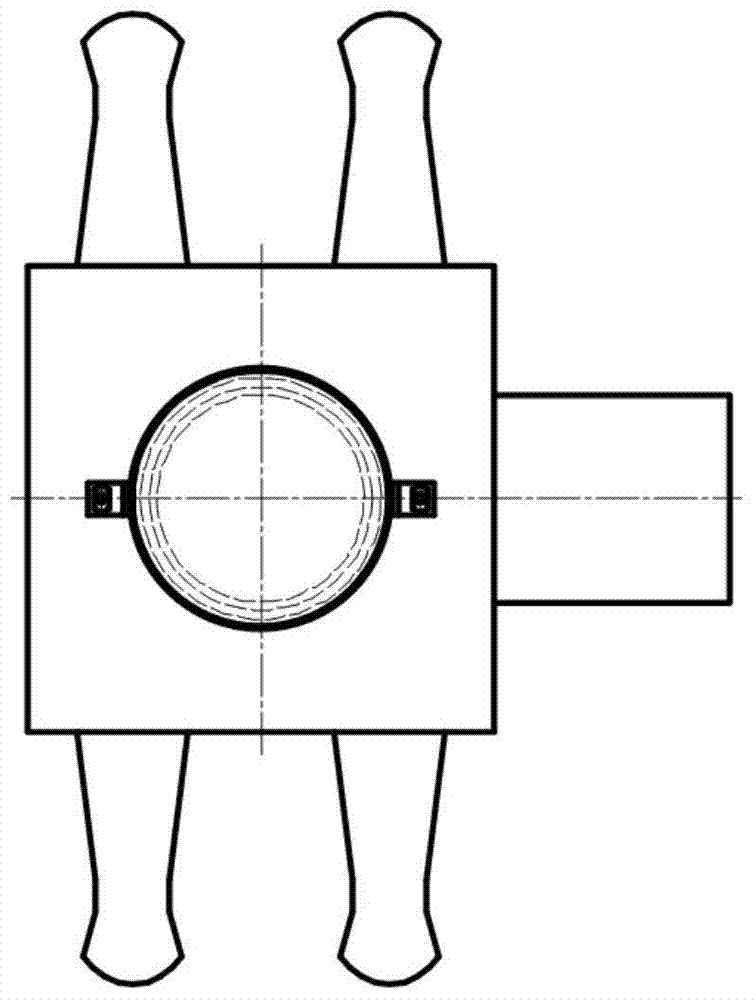

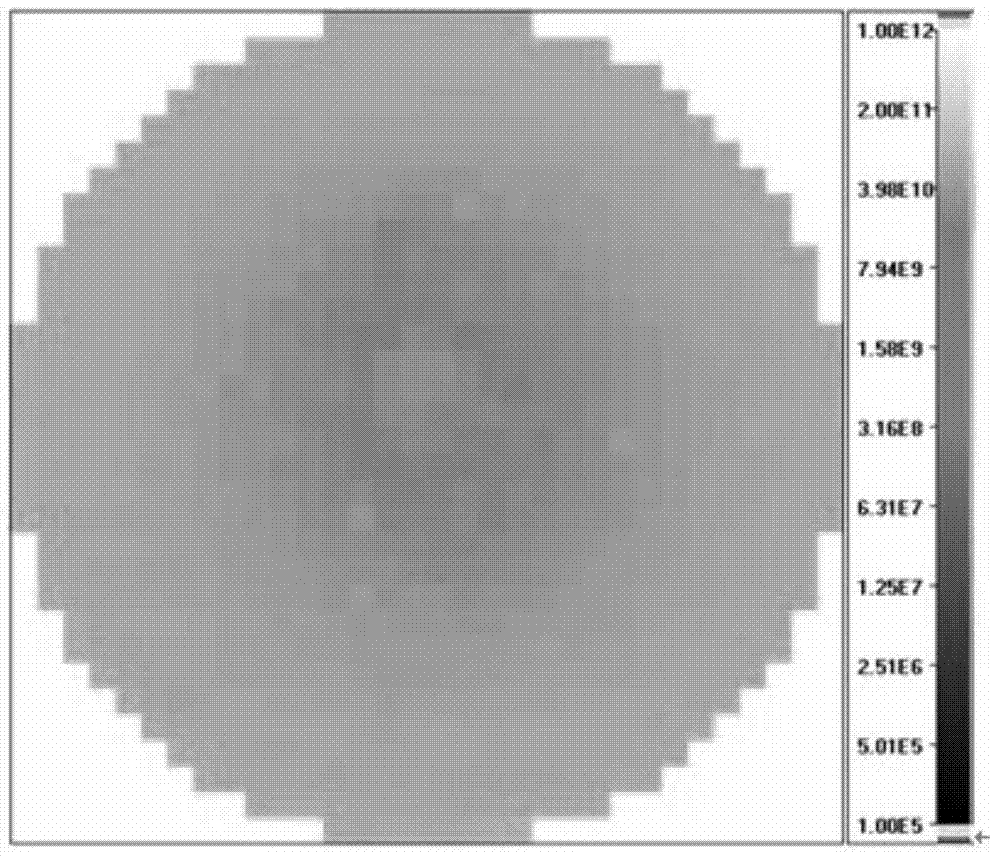

[0043] A method for growing a high-purity semi-insulating SiC single crystal, realized by the following device for growing a high-purity semi-insulating silicon carbide single crystal;

[0044] The device comprises a growth chamber, the growth chamber adopts a lower opening method, an induction heater is arranged outside the growth chamber, an atmospheric isolation chamber is connected to the lower part of the growth chamber, an operation window is arranged on the atmospheric isolation chamber, and the atmospheric isolation chamber One side is connected with a transition chamber, the transition chamber is equipped with a heating device for removing impurities, the atmosphere isolation chamber and the transition chamber are equipped with a mechanism to keep the internal environment in a protective gas state or a vacuum state, and the lower part of the atmosphere isolation chamber is also Equipped with a vacuum cleaner interface;

[0045] Both the atmospheric isolation chamber a...

Embodiment 2

[0051] A method for growing a high-purity semi-insulating silicon carbide single crystal, realized by the following device for growing a high-purity semi-insulating SiC single crystal;

[0052] The device comprises a growth chamber, the growth chamber adopts a lower opening method, an induction heater is arranged outside the growth chamber, an atmospheric isolation chamber is connected to the lower part of the growth chamber, an operation window is arranged on the atmospheric isolation chamber, and the atmospheric isolation chamber One side is connected with a transition chamber, the transition chamber is equipped with a heating device for removing impurities, the atmosphere isolation chamber and the transition chamber are equipped with a mechanism to keep the internal environment in a protective gas state or a vacuum state, and the lower part of the atmosphere isolation chamber is also Equipped with a vacuum cleaner interface;

[0053] Both the atmospheric isolation chamber a...

Embodiment 3

[0061] A method for growing a high-purity semi-insulating silicon carbide single crystal, realized by the following device for growing a high-purity semi-insulating SiC single crystal;

[0062] The device comprises a growth chamber, the growth chamber adopts a lower opening method, an induction heater is arranged outside the growth chamber, an atmospheric isolation chamber is connected to the lower part of the growth chamber, an operation window is arranged on the atmospheric isolation chamber, and the atmospheric isolation chamber One side is connected with a transition chamber, the transition chamber is equipped with a heating device for removing impurities, the atmosphere isolation chamber and the transition chamber are equipped with a mechanism to keep the internal environment in a protective gas state or a vacuum state, and the lower part of the atmosphere isolation chamber is also Equipped with a vacuum cleaner interface;

[0063] Both the atmospheric isolation chamber a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com