Aluminum alloy product and preparation method thereof

A technology for aluminum alloy and cast aluminum alloy, applied in the field of aluminum alloy products and their preparation, can solve problems such as hindering application, uneven stains or gray spots, restrictions, etc., and achieves the reduction of CNC time, CNC cost, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

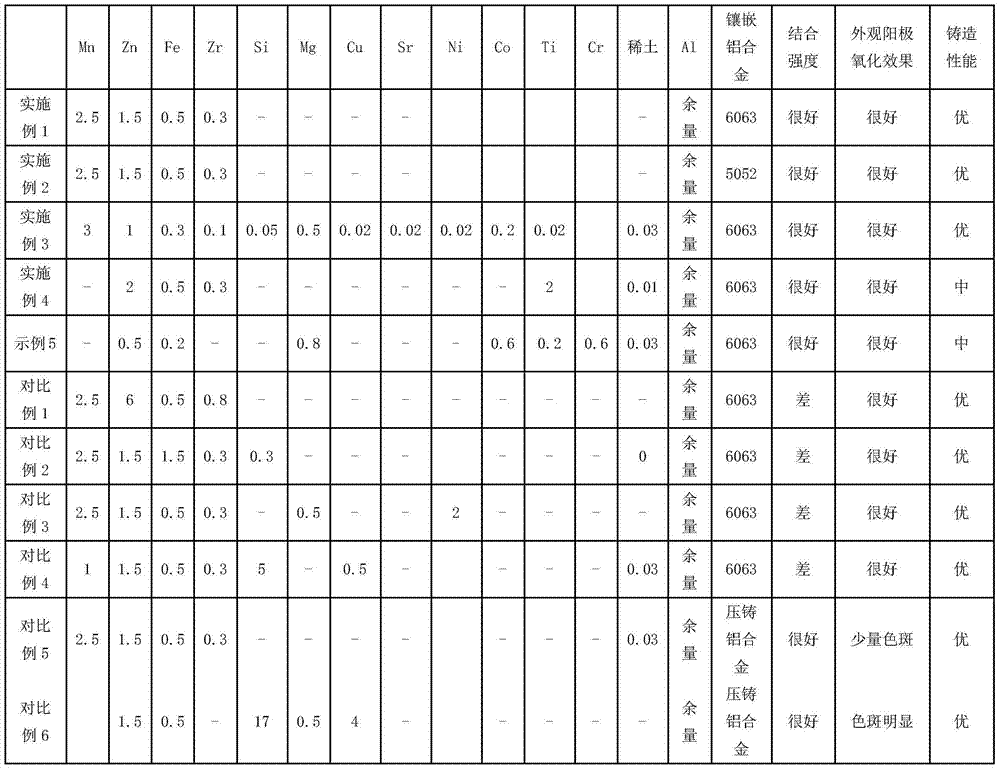

Embodiment 1

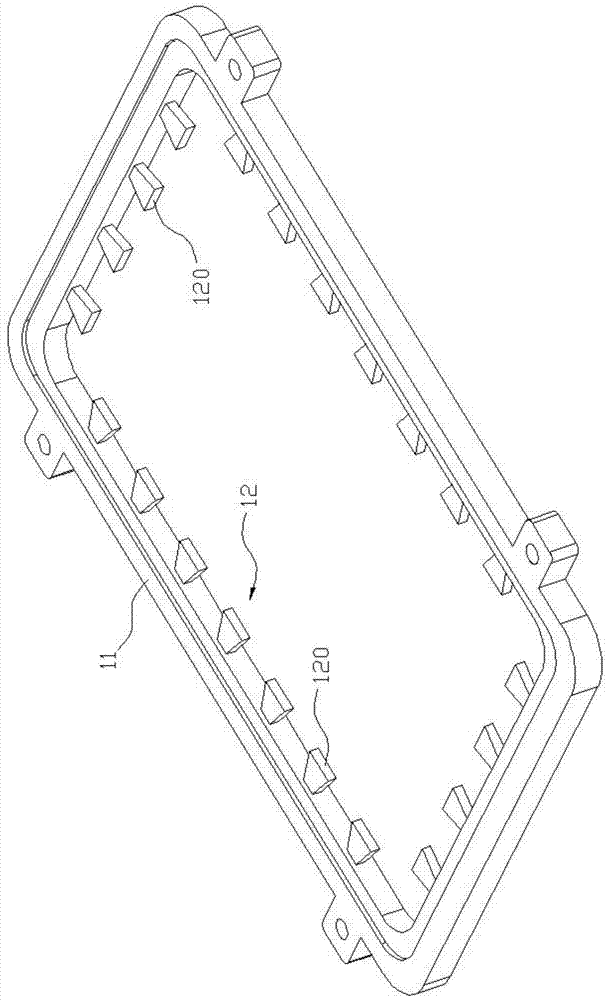

[0033] (1) Take the section as figure 1 6063 aluminum alloy profiles with a thickness of 4mm are used as inserts and put into die-casting molds;

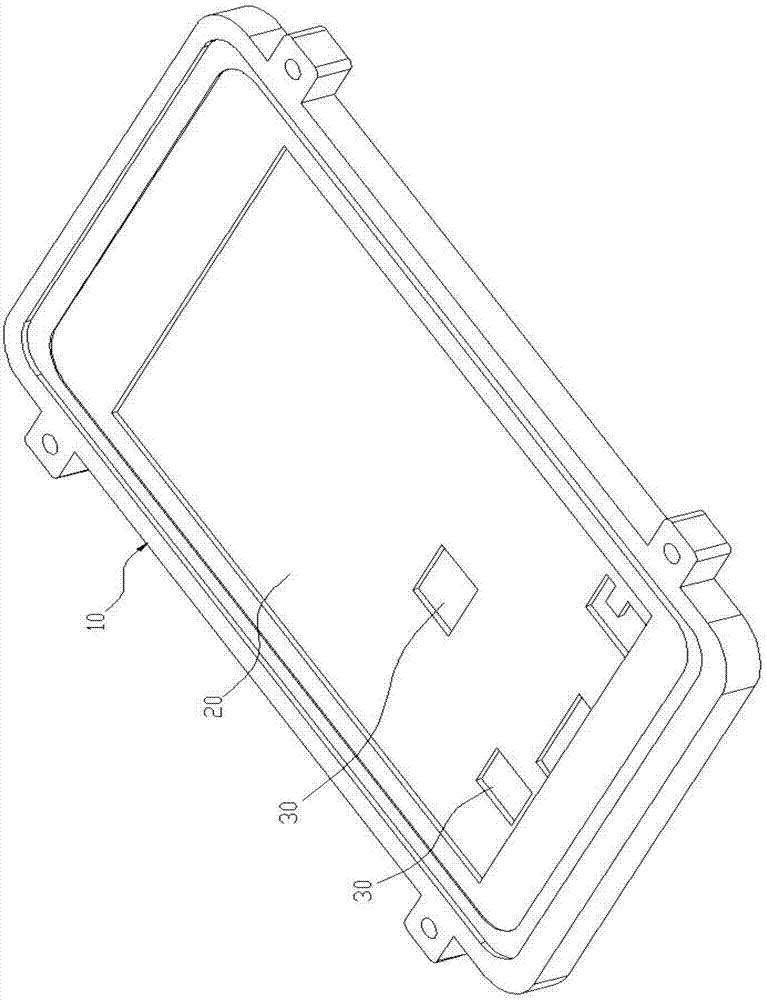

[0034] (2) Melting in a graphite crucible, refining the die-casting aluminum alloy according to the proportioning composition in Table 1, degassing and slag removal, etc., the refining temperature is 700°C, the refining time is 30 minutes, and the refined alloy is injected into the die-casting chamber , and then cast into a mold to form the aluminum alloy product of the present invention, such as figure 2 Show.

[0035] The outer surface of the die casting is machined and polished.

[0036] Anodizing treatment: after degreasing the aluminum alloy products, neutralize the workpiece with lye, put the pre-treated aluminum alloy products into the anode tank solution, the sulfuric acid concentration is 200g / L, and the voltage is controlled at 13V and 20°C Electrolyze for 25 minutes, wash and dry; use a film thickness meter to measure...

Embodiment 2

[0042] The difference from the example is that the insert is made of 5052 aluminum alloy with a coefficient of linear expansion of 22.9×10 -6 K -1.

[0043] The prepared aluminum alloy product has no visible cracks and joint gaps.

Embodiment 3

[0045] The difference from Example 1 is that the die-casting aluminum alloy has the alloy composition in Table 1, and the coefficient of linear expansion is: 23×10 -6 K -1 .

[0046] The prepared aluminum alloy product has no visible cracks and joint gaps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com