Long-afterglow luminescent material and preparation method thereof

A long afterglow luminescence and general formula technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of limiting the application of long afterglow luminescent materials and the shortage of long afterglow luminescent materials, and achieve the effect of long afterglow time and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040]The present invention also provides a method for preparing the long-lasting luminescent material described in the above technical solution, comprising the following steps:

[0041] a) mixing a barium source, a silicon source, a europium source and a doping metal source, and roasting in a reducing atmosphere to obtain a long-lasting luminescent material;

[0042] The long afterglow luminescent material has the general formula shown in formula (I):

[0043] Ba (1-x-y) SiO 3 :xEu 2+ ,yR 3+ Formula (I);

[0044] In formula (I), R is one or more of Sc, Y, La, Ce, Pr, Nd, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu;

[0045] 0.0001≤x≤0.2; 0.0001≤y≤0.2.

[0046] In the present invention, a barium source, a silicon source, a europium source and a dopant metal source are mixed. In the present invention, the barium source preferably includes one or more of barium oxide, barium carbonate, barium phosphate, barium nitrate and barium oxalate, more preferably barium Carbonate; In a p...

Embodiment 1

[0059] Take 3.1555g BaCO 3 (analytical pure), 1.0007g SiO 2 (analytical pure), 0.0586g Eu 2 o 3 (99.99%) and 0.0561g Nd 2 o 3 (99.99%) mixed, fully ground to obtain a mixture.

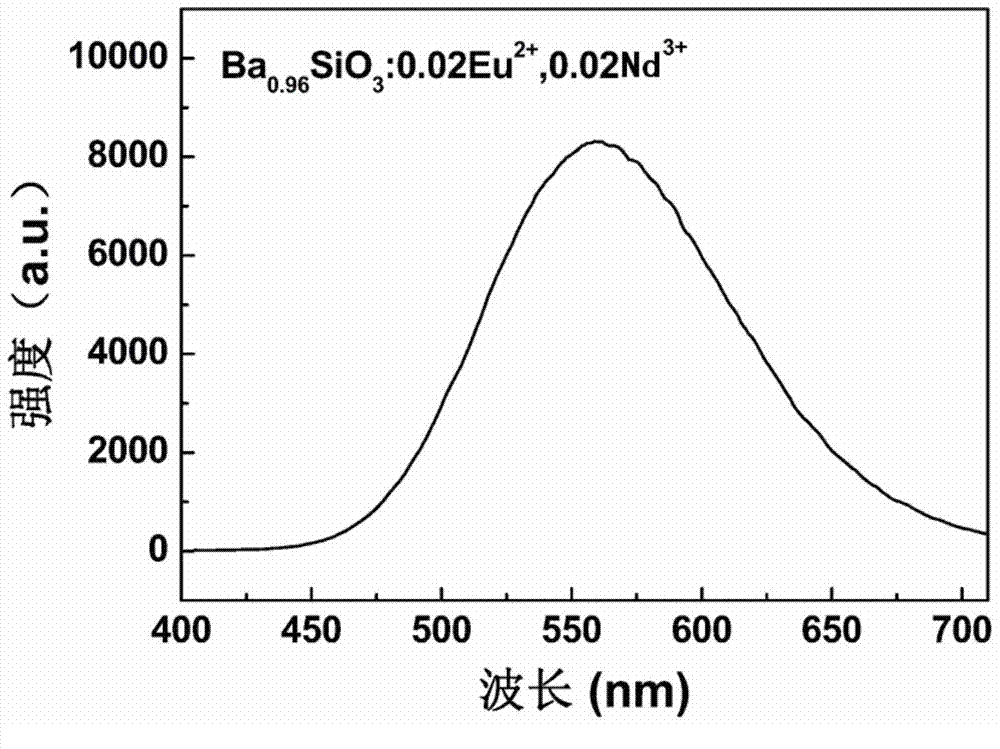

[0060] Put the mixture into a corundum crucible, put the above corundum crucible with the mixture into a high-temperature furnace, and bake it at 1400°C for 6 hours in the presence of CO, cool it down to room temperature naturally, take it out and grind it, and obtain a light yellow The powdered product is the long afterglow luminescent material Ba 0.96 SiO 3 :0.02Eu 2+ ,0.02Nd 3+ .

[0061] Gained product is carried out X-ray diffraction analysis, used instrument is German Bruker / D8-FOCUS X-Ray Diffractometer, radiation source is Cu Kα1 (λ=1.5405nm), scanning range: 2θ=10 °~70 °, scanning speed 10 ° / min. See results figure 1 , figure 1 The long afterglow luminescent material and JCPDS 26-1402 card (BaSiO 3 ) XRD diffraction pattern. Depend on figure 1 It can be seen that the sample obt...

Embodiment 2

[0064] Take 3.1555g BaCO 3 (analytical pure), 1.0007g SiO 2 (analytical pure), 0.0586g Eu 2 o 3 (99.99%) and 0.0561g Nd 2 o 3 (99.99%) mixed, and added 0.02g H 3 BO 3 , fully ground to obtain a mixture.

[0065] Put the mixture into a corundum crucible, put the above corundum crucible with the mixture into a high-temperature furnace, and bake it at 1300°C for 6 hours in the presence of CO, cool it down to room temperature naturally, take it out and grind it, and get a light yellow The powdered product is the long afterglow luminescent material Ba 0.96 SiO 3 :0.02Eu 2+ ,0.02Nd 3+ .

[0066] The obtained product is carried out X-ray diffraction analysis according to the method for embodiment 1, and the result sees figure 1 . figure 1 The long afterglow luminescent material and JCPDS 26-1402 card (BaSiO 3 ) XRD diffraction pattern. Depend on figure 1 It can be seen that the sample obtained in Example 2 and BaSiO 3 have the same structure.

[0067] Excitation spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com