Fluoride-containing polyurethane CO2 gas soluble foaming agent and preparation method and use thereof

A technology based on polyurethane and CO2, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that do not involve the gas-soluble foaming agent co-solvent system, etc., so as to avoid the problem of easy corrosion, improve solubility, and improve The effect of solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

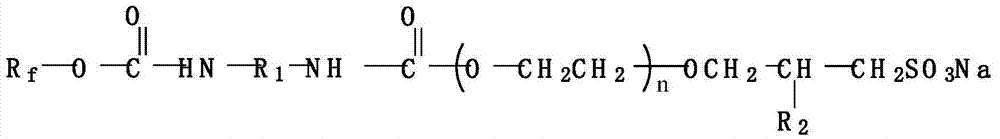

Method used

Image

Examples

Embodiment 1

[0035] In a dry three-necked flask with a stirrer, a condenser and a dropping funnel, add 0.6 mol of dodecafluoroheptanol and 0.5 mol of toluene 2,4-diisocyanate dropwise, add 0.03 mol of dibutyltin dilaurate, Raise the temperature to 60°C and reflux for 9 hours; then add 0.6 mol of allyl polyoxyethylene (14) ether dropwise, and continue to reflux for 5 hours. The product is precipitated by petroleum ether and dissolved in chloroform to remove excess alcohol and ether to obtain dodecafluoro Heptane Tetradecyl Polyoxyethylene Ether Polyurethane.

[0036] Add 20mol of water to the reaction vessel with stirrer, condenser and dropping funnel, add 0.2mol of dodecafluoroheptane allyl polyoxyethylene (14) ether polyurethane, 0.015mol of hexadecyl trimethyl Ammonium Bromide, 0.4mol NaHSO 3 , heated to 90°C, reacted for 10 h, extracted the mixed liquid with petroleum ether, and removed the solvent by rotary evaporation to obtain sodium dodecafluoroheptane tetraallyl polyoxyethylene et...

Embodiment 2

[0038] Add 0.11mol of hexadecafluorononanol and 0.1mol of isophorone diisocyanate dropwise to a three-necked flask with a stirrer, a condenser and a dropping funnel, add 0.008mol of stannous octoate, heat up to 80°C, and reflux After 7 hours; add 0.11mol of methallyl polyoxyethylene (44) ether dropwise, and continue to reflux for 8 hours. The product is precipitated by petroleum ether and dissolved in chloroform to remove excess alcohol and ether, and hexadecafluorononane 44 can be obtained. Tetraallyl polyoxyethylene ether polyurethane.

[0039] Add 10 mol of water into the reaction vessel with stirrer, condenser and dropping funnel, add 0.1 mol of hexadecafluorononyl allyl polyoxyethylene (44) ether polyurethane, 0.007 mol of 18 crown 6 ether, 0.15 mol of NaHSO 3 , heated up to 110°C, reacted for 6 hours, extracted the mixed liquid with petroleum ether, and removed the solvent by rotary evaporation to obtain hexadecafluorononyl tetratetratrasallyl polyoxyethylene ether sodi...

Embodiment 3

[0041] In a dry three-necked flask with a stirrer, a condenser and a dropping funnel, add 0.6 mol of tetrafluoropropanol and 0.6 mol of hexamethylene-diisocyanate dropwise, add 0.0006 mol of triethylamine, and heat up to 30°C. After reflux for 30 hours; add 0.6 mol of allyl polyoxyethylene (10) ether dropwise, continue to reflux for 1 hour, the product is precipitated by petroleum ether, dissolved in chloroform to remove excess alcohol and ether, and tetrafluoropropyl allyl polyethene can be obtained. Oxyethylene(10) ether polyurethane.

[0042] Add 12 mol of water to the reaction vessel with stirrer, condenser and dropping funnel, add 0.2 mol of tetrafluoropropyl allyl polyoxyethylene (10) ether polyurethane, 0.02 mol of polyethylene glycol 400, 0.2 mol of NaHSO 3 , heated to 50° C., reacted for 15 hours, extracted the mixed liquid with petroleum ether, and removed the solvent by rotary evaporation to obtain sodium tetrafluoropropane allyl polyoxyethylene (10) ether polyureth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com