Solar battery backboard material with high weather resistance and preparation method thereof

A solar cell and weather resistance technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to meet the needs of use, serious environmental pollution, and high manufacturing costs, and achieve excellent weather resistance, simple preparation process, and excellent environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

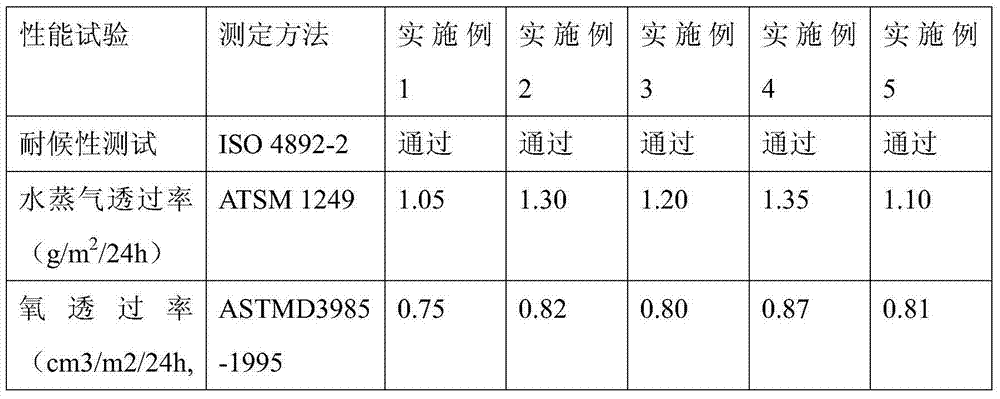

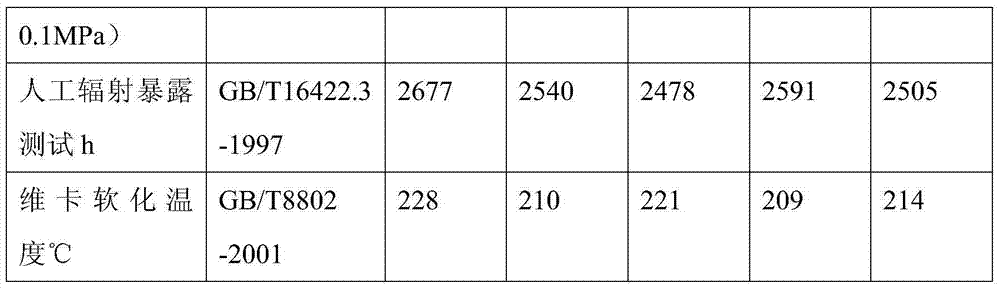

Examples

Embodiment 1

[0014] Example 1: A solar cell backsheet material with high weather resistance, comprising the following components in parts by weight: 48 parts of PET, 27 parts of PETG, 1.5 parts of glass micropowder, 13 parts of nanomaterials, 1.2 parts of ultraviolet absorber, photostable Agent GW-540 2.8 parts, anti-aging agent 1.5 parts, antioxidant 0.8 parts, stabilizer 3.5 parts. The ultraviolet absorber is a compound of UV-317 and UV-326 with a mass ratio of 1:1, and the antioxidant is a compound of antioxidant CA and antioxidant 264 with a mass ratio of 1:1. The stabilizer is polycarbodiimide, the nano material is nano titanium dioxide, and the anti-aging agent is a hindered amine anti-aging agent.

[0015] The preparation method of the above-mentioned high weather resistance solar cell backboard material comprises the following steps: taking the required raw materials according to the weight ratio and placing them in the mixer, stirring for 8 minutes at a speed of 5500r / min, and sti...

Embodiment 2

[0016] Example 2: A solar cell backsheet material with high weather resistance, comprising the following components in parts by weight: 45 parts of PET, 25 parts of PETG, 1 part of glass micropowder, 10 parts of nanomaterials, 0.8 parts of ultraviolet absorber, photostable 2.5 parts of agent GW-540, 1 part of anti-aging agent, 0.6 parts of antioxidant, and 3 parts of stabilizer. The UV absorber is selected from UV-317, the antioxidant is a compound of antioxidant CA and antioxidant 264 with a mass ratio of 1:1, the stabilizer is carboimide phenyl ester, and the The nano material is nano calcium carbonate, and the anti-aging agent is selected from benzophenone anti-aging agent.

[0017] The preparation method of the above-mentioned high weather resistance solar cell backboard material comprises the following steps: take the required raw materials according to the weight ratio and place them in the mixer, stir at 5000r / min for 10min, and the raw materials after stirring Dry at ...

Embodiment 3

[0018] Example 3: A solar cell backsheet material with high weather resistance, comprising the following components by weight: 50 parts of PET, 30 parts of PETG, 2 parts of glass micropowder, 15 parts of nanomaterials, 1.5 parts of ultraviolet absorber, light stable 3 parts of agent GW-540, 2 parts of anti-aging agent, 1 part of antioxidant, 4 parts of stabilizer. The UV absorber is selected from UV-326, the antioxidant is a compound of antioxidant CA and antioxidant 264 with a mass ratio of 1:1, the stabilizer is polycarbodiimide, and the The nano-material is a mixture of nano-titanium dioxide, nano-alumina, and nano-calcium carbonate, and the anti-aging agent is a hindered amine anti-aging agent.

[0019] The preparation method of the above-mentioned highly weather-resistant solar cell backboard material comprises the following steps: taking the required raw materials according to the weight ratio and placing them in the mixer, stirring for 5 minutes at a speed of 6000r / min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com