Low-temperature sintered lead-free microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and low-temperature sintering, applied in the field of ceramic materials, can solve problems such as difficult to achieve comprehensive properties of dielectric materials, unfavorable rapid transmission of electrical signals, etc., and achieve excellent dielectric properties and high solid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure and characteristics of a low-temperature sintered lead-free microwave dielectric ceramic proposed according to the present invention will be described below in conjunction with the preferred embodiments. , preparation method and efficacy thereof are described in detail as follows.

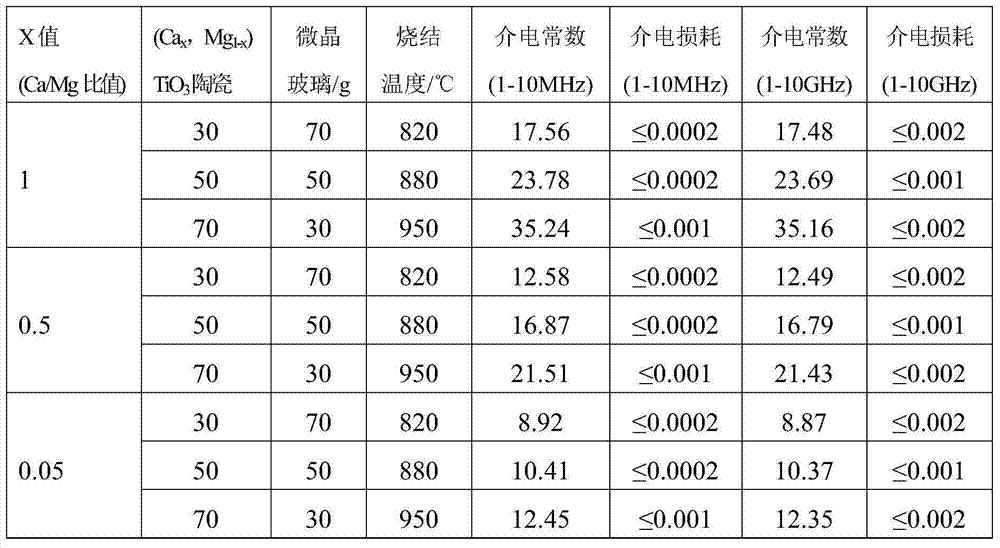

[0029] The invention provides a low-temperature sintered lead-free microwave dielectric ceramic, which is made of the following raw materials in mass percentage: (Ca x , Mg 1-x )TiO 3 : 10-60wt%; CaO-Al2 o 3 -B 2 o 3 -SiO 2 Glass-ceramics: 40-90wt%; where: 0<x<1.

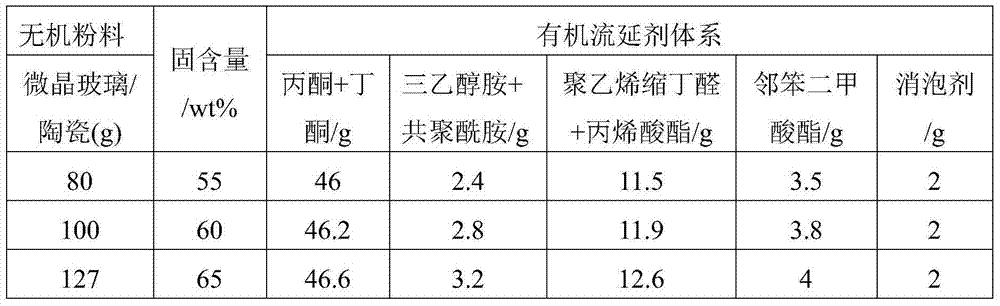

[0030] The invention provides a method for preparing low-temperature sintered lead-free microwave dielectric ceramics, which comprises the following steps:

[0031] Raw material CaCO 3 , MgCO 3 、TiO 2 According to the formula (Ca x , Mg 1-x )TiO 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com