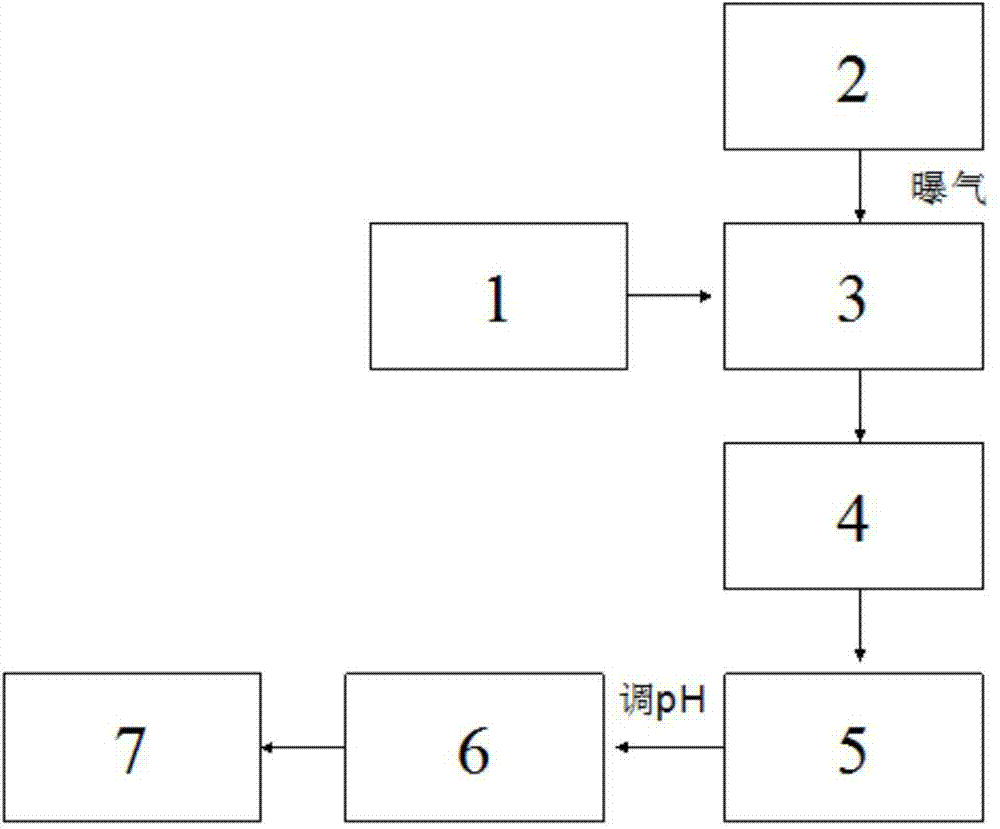

Iron-carbon inner electrolysis-Fenton oxidation-electrolytic electrocatalytic oxidation combined wastewater treatment method and device

An electrolytic catalytic oxidation and electrocatalytic oxidation technology, applied in the field of composite treatment, can solve problems such as limiting the practical application of wastewater treatment, and achieve the effects of improving biodegradability, saving resources, and feasible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Put 1L of waste water with an initial COD content of 32000mg / L and BOD / COD less than 0.1 into the inner electrolysis packed tower by an air pump. The filler uses self-made mixed particles with a volume ratio of iron and carbon of 1:1, and adjusts the pH to 2.5. Aeration, after treatment; through the Fenton pool, add 20g H 2 o 2 Solution, adjust the pH to 2 for oxidation reaction, after the reaction is completed; enter the electrolytic cell for electrolytic oxidation, the electrolytic anode material is made of titanium-based doped Pr metal oxide material, the preparation method refers to Z.He, C.Huang, Q . Wang, Z. Jiang, J. Chen, S. Song, Int. J. Electrochem. Sci. 6 (2011) 4341–4354. Control the current density, electrolysis voltage, adjust the electrolysis process, and the treatment is completed; adjust the pH to 8.5, and discharge through the effluent pool after the coagulation and sedimentation process is completed in the effluent coagulation sedimentation tank. ...

Embodiment 2

[0029] Put 1L of waste water with an initial COD content of 33000mg / L and BOD / COD less than 0.1 into the inner electrolytic packing tower by an air pump. The filler uses self-made mixed particles with a volume ratio of iron to carbon of 1:2.5, adjusts the pH to 2.5, and aerates , after the treatment is completed; through the Fenton oxidation process, add 20g H 2 o 2 Solution, adjust the pH to 3, after the reaction is complete; carry out electrolysis, the electrolysis anode material adopts the titanium-based doped Bi metal oxide material made by oneself, and the preparation method refers to C.A.Martínez-Huitle, E.Brillas, Appl.Catal.B:Environ .87 (2009) 105–145. Control the current density and electrolysis voltage, adjust the electrolysis process, and the treatment is completed; adjust the pH to 8, and the coagulation and precipitation process is completed. The COD content of the effluent is 8200mg / L, the COD removal rate is 75.2%, and the BOD / COD is 0.38.

Embodiment 3

[0031] Put 1L of waste water with an initial COD content of 34000mg / L and BOD / COD less than 0.1 into the inner electrolysis packing tower by an air pump. The filler uses self-made mixed particles with an iron-carbon volume ratio of 1:5, adjusts the pH to 2.5, and aerates , after the treatment is completed; through the Fenton oxidation process, add 20g H 2 o 2 Solution, adjust the pH to 6, after the reaction is completed; carry out electrolysis, the electrolysis anode material adopts titanium-based doped Ta metal oxide and Pr metal oxide materials made by oneself, and the preparation method refers to G.Chen, Sep.Purif.Technol.38 (2004) 11–41., the mass ratio of Ta metal oxide and Pr metal oxide is 2:1. Control the current density, electrolysis voltage, adjust the electrolysis process, and the treatment is completed; adjust the pH to 8.5, and the coagulation and precipitation process is completed. The COD content of the effluent is 7400mg / L, the COD removal rate is 78.2%, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com