Hydraulic brake kinetic energy recovery system for vehicle

A kinetic energy recovery system and hydraulic technology, applied in vehicle parts, auxiliary drive devices, control devices, etc., can solve problems such as affecting the operation and the health of passengers, failing to be widely promoted and applied, and increasing the weight of the whole vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

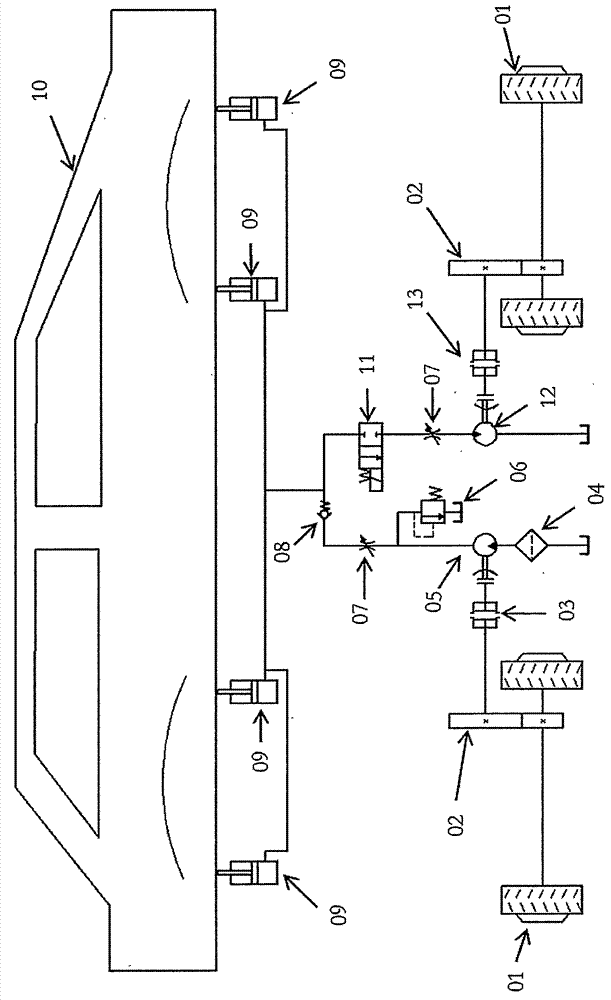

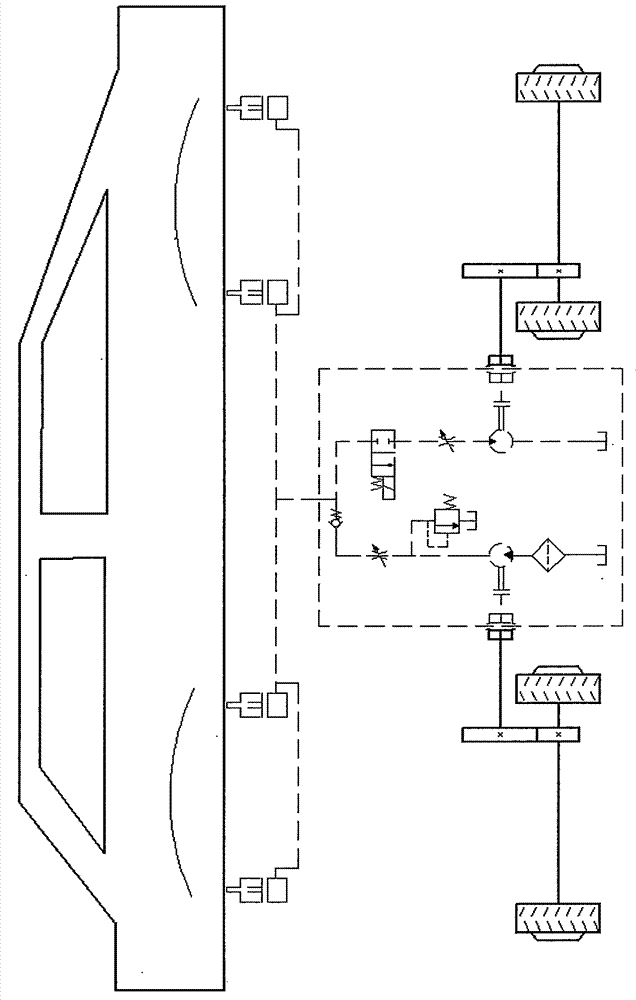

[0013] When the vehicle is running normally, the braking clutch 03 and the driving clutch 13 are both in the disengaged state, and the hydraulic brake kinetic energy recovery system is in the non-working state, such as figure 2 shown.

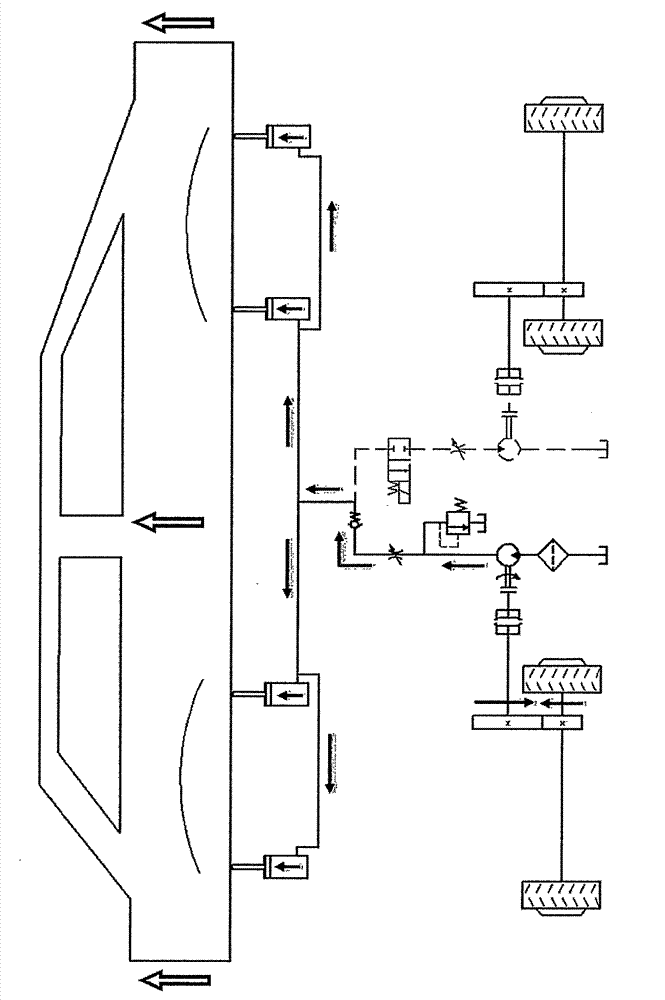

[0014] When the driver steps on the brake pedal, the braking process starts, the brake clutch 03 is engaged, the drive clutch 13 is separated, the reversing valve 11 is switched to the closed state, the rotation of the wheel is transmitted to the brake clutch through the transmission gear 02, and drives the hydraulic pump 05 rotates and starts to deliver oil to the hydraulic cylinder 09. After the hydraulic cylinder 09 is extended, the vehicle body 10 is lifted upwards, and the braking kinetic energy is converted and stored as the gravitational potential energy of the vehicle body, thereby realizing the energy recovery process. During this process, the filter 04 plays the role of cleaning the oil circuit, the overflow 08 plays the role of pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com