A universal self-aligning loading mechanism for the upper plate of a double-sided polishing machine

A double-sided polishing machine and loading mechanism technology, applied in grinding/polishing equipment, grinding/polishing safety devices, grinding machine tools, etc., can solve the problem of fragile and cracked workpieces, sudden changes in workpiece force, and the coincidence of two working surfaces Problems such as the inability to guarantee the peace and parallelism can achieve the effect of ensuring the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

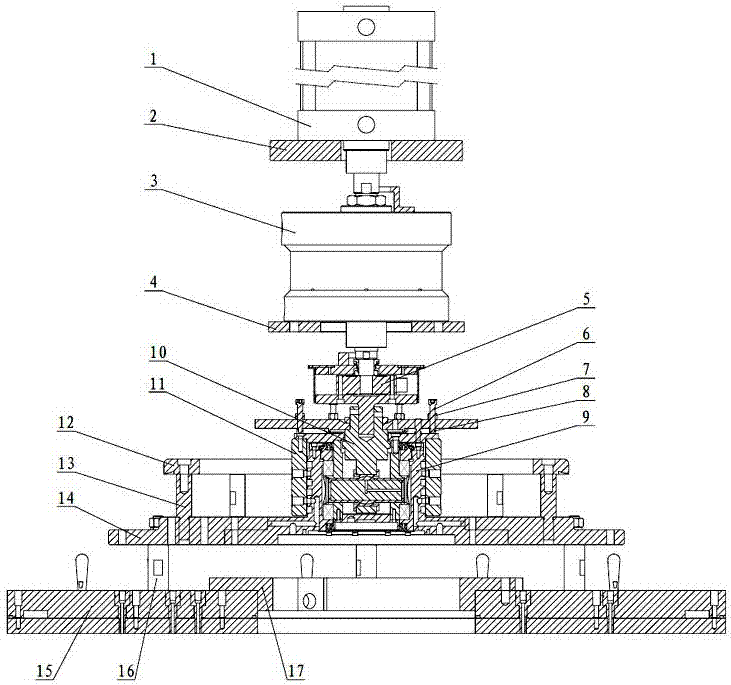

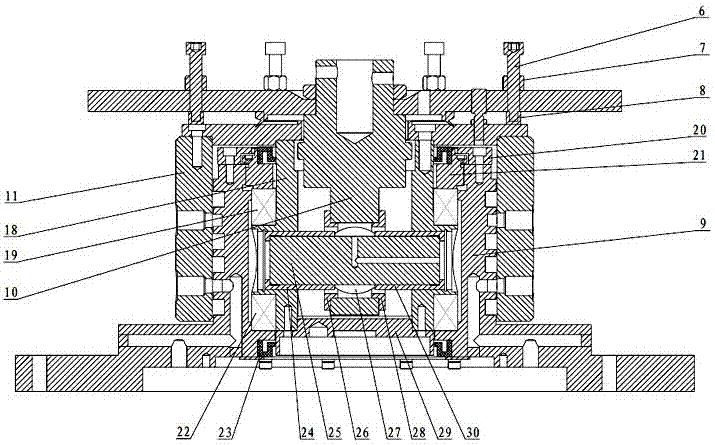

[0020] refer to figure 1 and figure 2 As shown, a universal self-aligning loading mechanism for the upper plate of a double-sided polishing machine includes a main cylinder 1 as a source of positive pressure and back pressure. The main cylinder 1 is fixed to the frame beam through the cylinder mounting plate 2. The main cylinder The auxiliary cylinder 3 is connected under the cylinder 1, which effectively ensures the buffering and unloading of the pressure inertia when the upper plate and the lower plate are combined, thereby protecting the processed parts from breaking when the two plates are combined. The lower end of the auxiliary cylinder is fixed with a guide rod The support plate 4, the piston rod of the auxiliary cylinder 3 is connected to the connecting rod 10 below through the tension sensor 5, so as to ensure that the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com