Double-layer vierendeel truss structure system of large cantilever structure

A technology of hollow truss and large cantilever, applied in truss-type structures, girders, trusses and other directions, can solve problems such as deformation, achieve the effect of convenient construction, meet the requirements of structural stress and deformation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

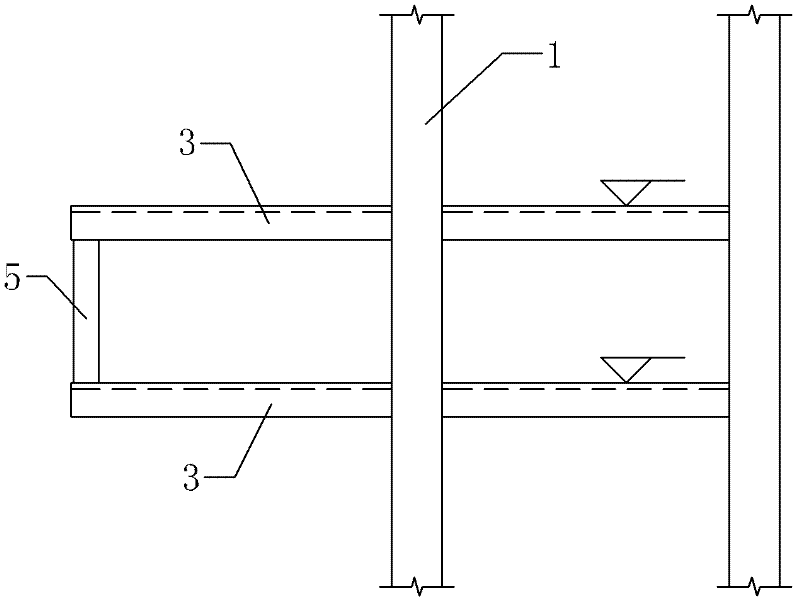

[0020] Figure 1 to Figure 5 Constitute the specific embodiment 1 of the present invention.

[0021] refer to Figure 1 to Figure 5 , the present embodiment includes a floor frame, and the floor frame is composed of frame columns 1, frame beams 2 and cantilever beams 3, and several main truss columns 4 are arranged between the upper and lower frame beams 2 of the floor, and through the The upper and lower frame beams 2 are connected with the main truss columns 4 to form a vierendeel truss structure on the first floor; several secondary truss columns 5 are arranged between the upper and lower cantilever beams 3 of the floor, and through the upper and lower suspension of the floor The cantilever beam 3 is connected with the main truss column 4 and the secondary truss column 5 to form a second-layer hollow truss structure; the double-layer hollow truss with a large cantilever structure is formed by the first-layer hollow truss structure and the second-floor hollow truss structur...

specific Embodiment 2

[0027] The feature of this embodiment is: the frame beam 2 can be extended by at least one span to form an extension section (not shown in the accompanying drawings). There may be a rigid connection between the cantilever beam 3 and the extension section. All the other can be with specific embodiment 1.

[0028] In each embodiment of the present invention, the quantity of the main truss columns 4 between the upper and lower frame beams 2 of the floor can be determined according to the overall requirements of the architectural design, and can be two, three, five, six, seven, eight, Nine, ten, twelve, fifteen, seventeen, nineteen or more than twenty; corresponding to the number of main truss columns 4, the secondary truss columns between the upper and lower cantilever beams 3 of the floor The number of 5 can be determined according to the overall requirements of the architectural design, which can be two, three, five, six, seven, eight, nine, ten, twelve, fifteen, seventeen, ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com