A grinding device for pcd/cbn tool

A grinding and tool technology, applied in the direction of grinding machine parts, grinding/polishing equipment, other manufacturing equipment/tools, etc., can solve the problem of difficult to obtain the quality of the cutting edge and grinding efficiency of the tool, and achieve improved stability. High grinding quality, improve life and grinding efficiency, and achieve intelligent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

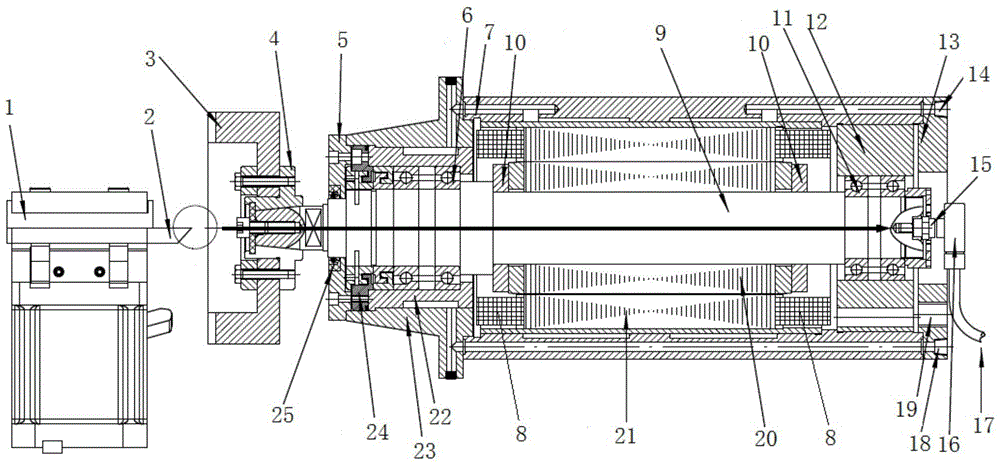

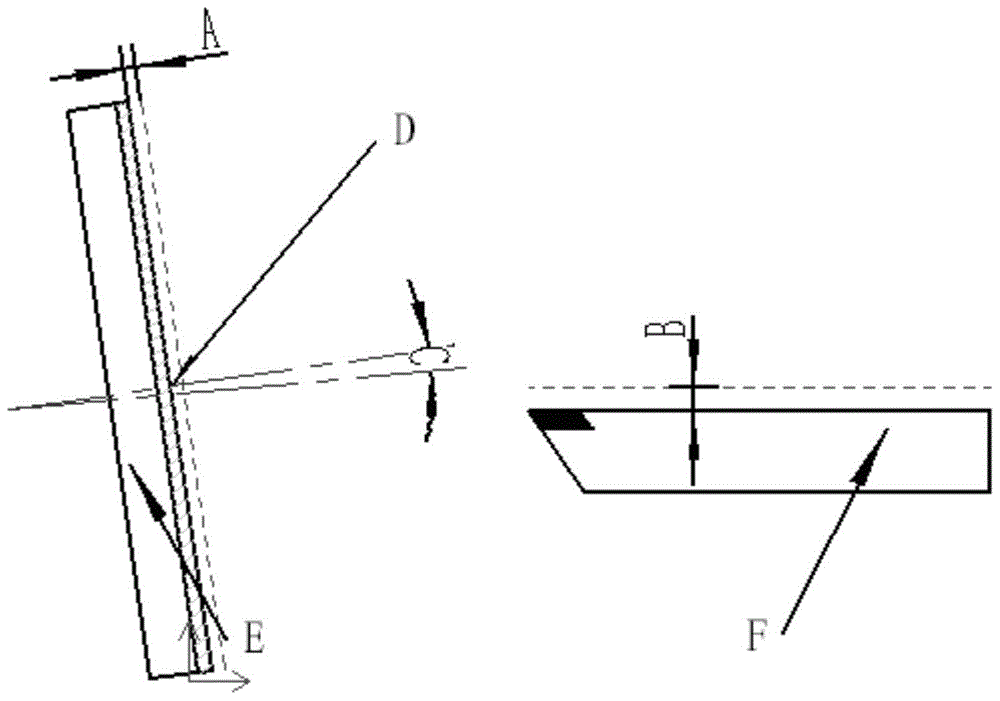

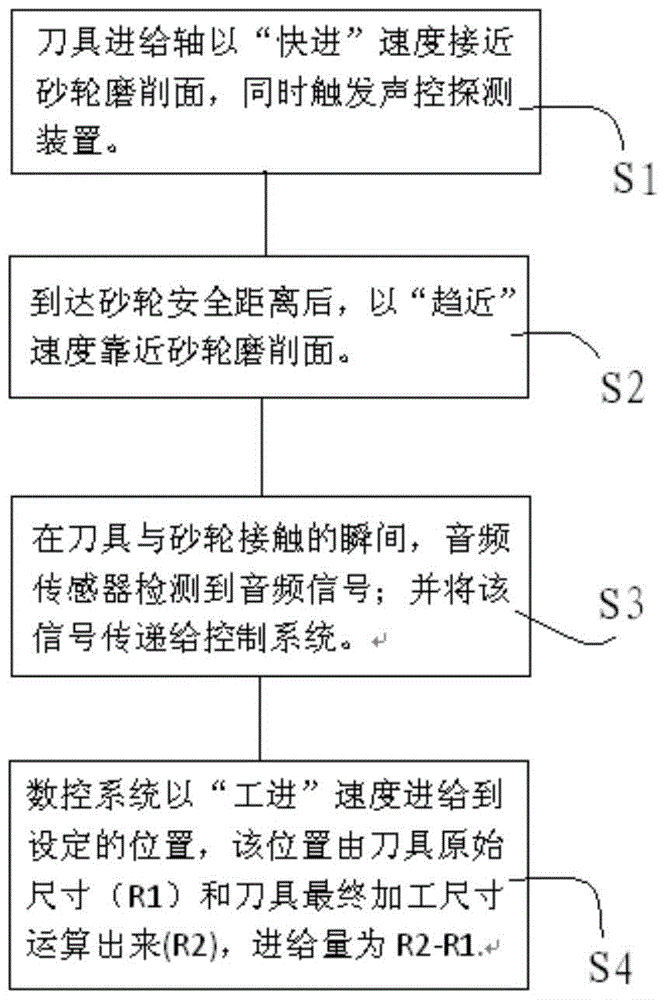

[0029]The present invention provides a grinding device for PCD / CBN tools. The grinding method adopted by the grinding device is the grinding method of the knife. For example, the main task of fine grinding of diamond tools is to accurately and stably control the grinding final dimensional accuracy. However, during the grinding process of diamond tools, changes in the position of the grinding wheel caused by changes in the inclination angle of the grinding wheel, wear on the end face of the grinding wheel, and changes in the thickness of the blade will all cause changes in the grinding point of the edge tip, which will eventually lead to machining errors. These factors have nothing to do with the motion accuracy of the machine tool, but are related to when to start grinding (that is, the tool setting point) and to what extent the grinding ends. The "knife grinding method" is to use audio sensors to accurately monitor the position of the grinding point to achieve precise control...

Embodiment 2

[0031] Application in grinding adaptive control: The main task of coarse grinding diamond is: to improve the grinding efficiency, that is, to set the safety distance as little as possible, and to reduce the time of "grinding" air; within the tolerance range of machine tool rigidity , remove the grinding allowance as soon as possible; find that the grinding allowance has been removed as early as possible (the sign is that the grinding resistance is reduced to the minimum); the friction between the grinding wheel and the diamond tool produces severe sound waves that propagate on the process equipment, and the monitoring of sound waves can be accurate It can accurately reflect the grinding status, such as whether the tool is in contact with the grinding wheel, whether the pressure between the tool and the grinding wheel (that is, the grinding resistance) is eliminated, etc. If the control system can collect and analyze this information in real time, so that the machine tool contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com