Organic adsorption saturated active carbon regeneration device

A regeneration device and activated carbon technology, which is applied in filter regeneration, chemical instruments and methods, and other chemical processes, can solve the problems of high labor intensity, easy damage of heating elements, and environmental pollution, and achieve high thermal energy utilization. The effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

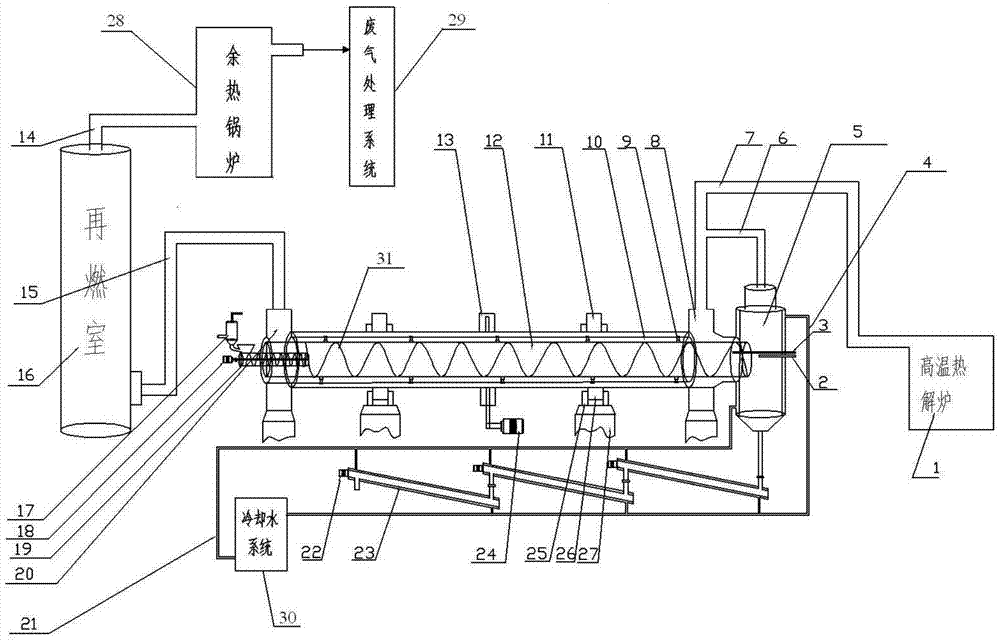

[0042] Attached below figure 2 , to describe the present invention in detail.

[0043] The high-temperature pyrolysis furnace 1 is placed at one end of the tail 8 of the gasification cracking furnace, and the heat source required for the regeneration of activated carbon comes from the industrial waste organic matter and waste oil burned in the high-temperature pyrolysis furnace 1 . Gas-solid separation device 5, gasification cracking furnace tail 8, reburning chamber 16, vacuum feeding device 17, activated carbon feeding motor 18, gasification cracking furnace burner 20, activated carbon cooling auger 23, transmission motor 24, roller chassis 25 , The roller device 26 is successively arranged on the foundation 27 through embedded bolts.

[0044] The rollers 11 are arranged in two roller devices 26 , and the two roller devices 26 are respectively arranged on the roller chassis 27 . The two ends of the body of furnace of gasification cracking furnace 12 are interspersed respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com