Preparation method of sponge with high oil-absorbing performance for oil-water separation

A technology for oil-water separation and high oil absorption, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of low oil absorption rate, complicated preparation process, long adsorption time, etc., and achieve cost reduction, simple process, and simple process. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

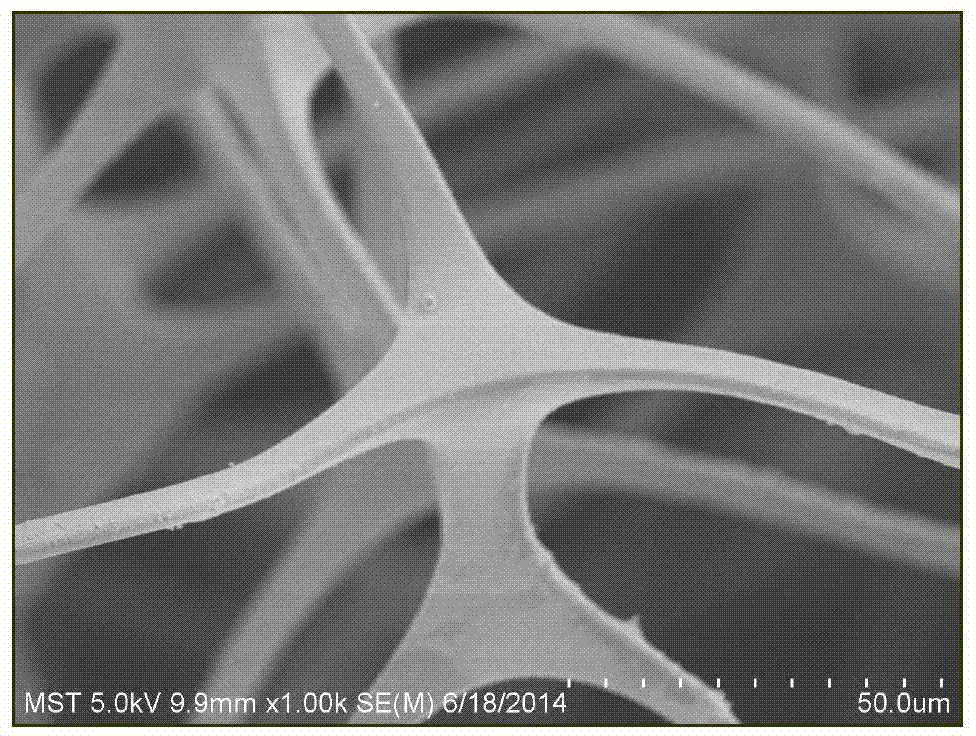

[0021] Take the polyurethane sponge and put it into a container, add a solution of γ-(methacryloyloxy)propyltrimethoxysilane (KH-570) with a mass concentration of 4% of the hydrophobic modifier prepared with ethanol as a solvent. The solution completely submerges the sponge, and the container is sealed. Stir at 50°C for 20 hours.

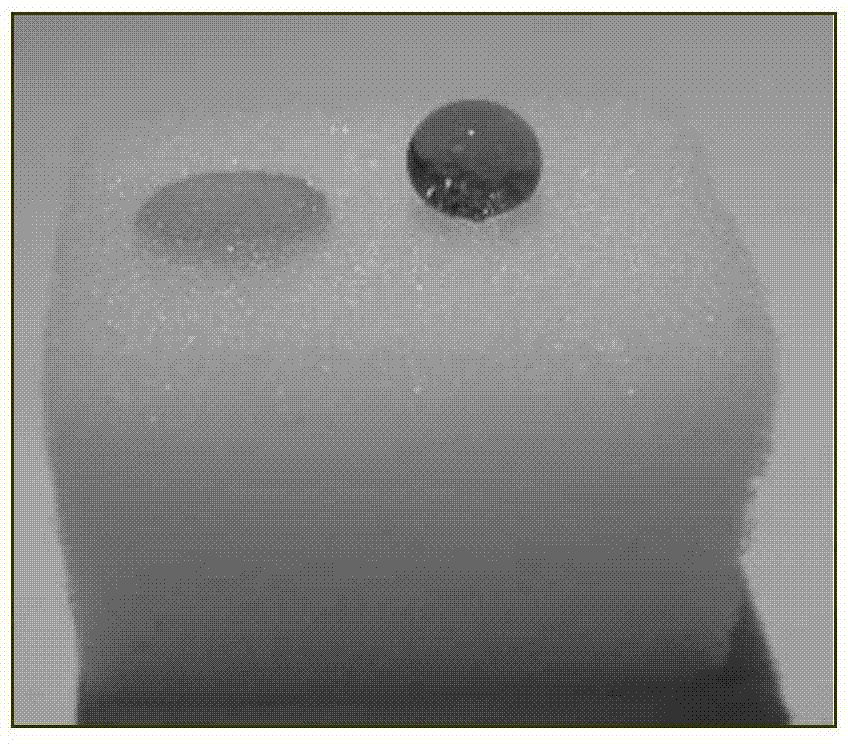

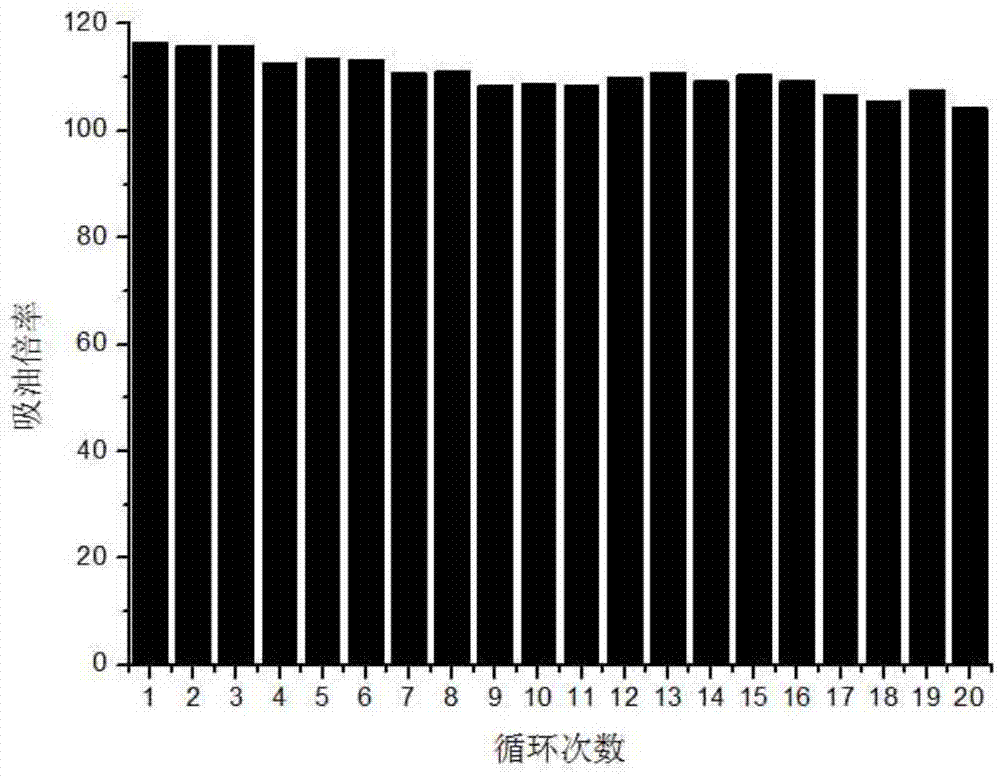

[0022] Heat and activate the sponge soaked in the hydrophobic modifier at 110° C. for 0.5 hour to obtain the oil-absorbing sponge. The oil absorption ratios of the oil-absorbing sponge obtained in this example to vegetable oil and lubricating oil are 118 times and 107 times of its own weight, respectively. The oil-absorbing sponge has excellent water-repellent and oil-absorbing characteristics. The oil droplets drop on the surface of the sponge and quickly penetrate into the interior of the sponge, leaving only a little oil on the surface; while the water droplets cannot penetrate into the oil-absorbing sponge, but remain in the shape of beads on t...

Embodiment 2

[0024] Put the polyurethane sponge into a container, add a 10% hydrophobic modifier KH-570 solution prepared with ethanol as a solvent, and require the solution to completely submerge the sponge and seal the container. Stir at 25°C for 1 hour.

[0025] Heat and activate the sponge soaked in the hydrophobic modifier at 75° C. for 16 hours to obtain the oil-absorbing sponge. The oil absorption rate of the sponge obtained in this embodiment to vegetable oil and lubricating oil is 94 times and 91 times of its own weight respectively.

Embodiment 3

[0027] Put the polyurethane sponge into a container, add a hydrophobic modifier-aminopropyltriethoxysilane (KH550) solution prepared with methanol as a solvent with a mass concentration of 5%, and require the solution to completely submerge the sponge and seal the container. Stir at 40°C for 10 hours.

[0028] Heat and activate the sponge soaked in the hydrophobic modifier at 50° C. for 20 hours to obtain the oil-absorbing sponge. The sponge obtained in the present embodiment has an oil absorption rate of 91 times of its own weight to vegetable oil and lubricating oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com