A kind of preparation method of fine-grain high-hardness tungsten-cobalt-nickel alloy

A high hardness, nickel alloy technology, applied in the field of powder metallurgy, can solve problems such as complex production process, uneven structure, complex shape, etc., and achieve the effect of high densification, fine tungsten grains, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

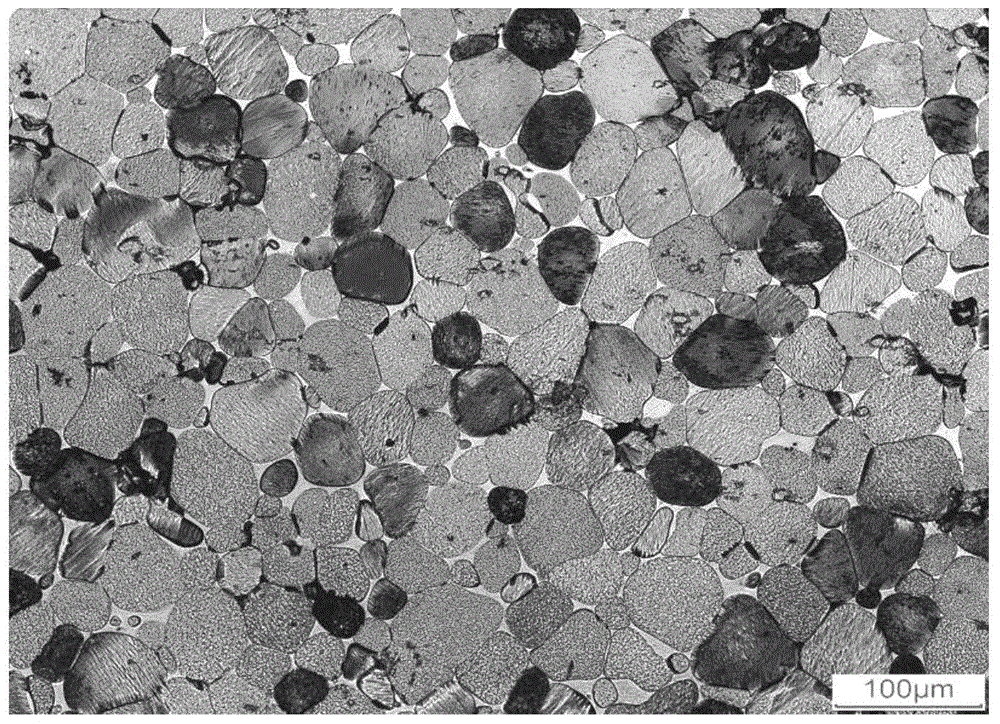

Embodiment 1

[0032] The preparation method of the fine-grained high-hardness tungsten-cobalt-nickel alloy of this embodiment comprises the following steps:

[0033] Step 1. Weigh tungsten powder, cobalt powder and nickel powder respectively by mass ratio W: Co: Ni=90: 5: 5; the Fischer particle size of the tungsten powder is 2.5 μm~3.5 μm, and the cost of the cobalt powder is The Fisherman's particle size is 1 μm to 2 μm, and the Fisherman's particle size of the nickel powder is 2.6 μm to 3.6 μm;

[0034] Step 2, adding the tungsten powder, cobalt powder and nickel powder weighed in step 1 into a mixer and mixing for 6 hours to obtain a mixed powder;

[0035] Step 3, using a cold isostatic press to press the mixed powder described in step 2 under a pressure of 150 MPa for 50 seconds to obtain a compact;

[0036] Step 4: Put the compact described in step 3 into a molybdenum wire pusher furnace, sinter at a temperature of 1500°C for 40 minutes to obtain a sintered compact, and then vacuum a...

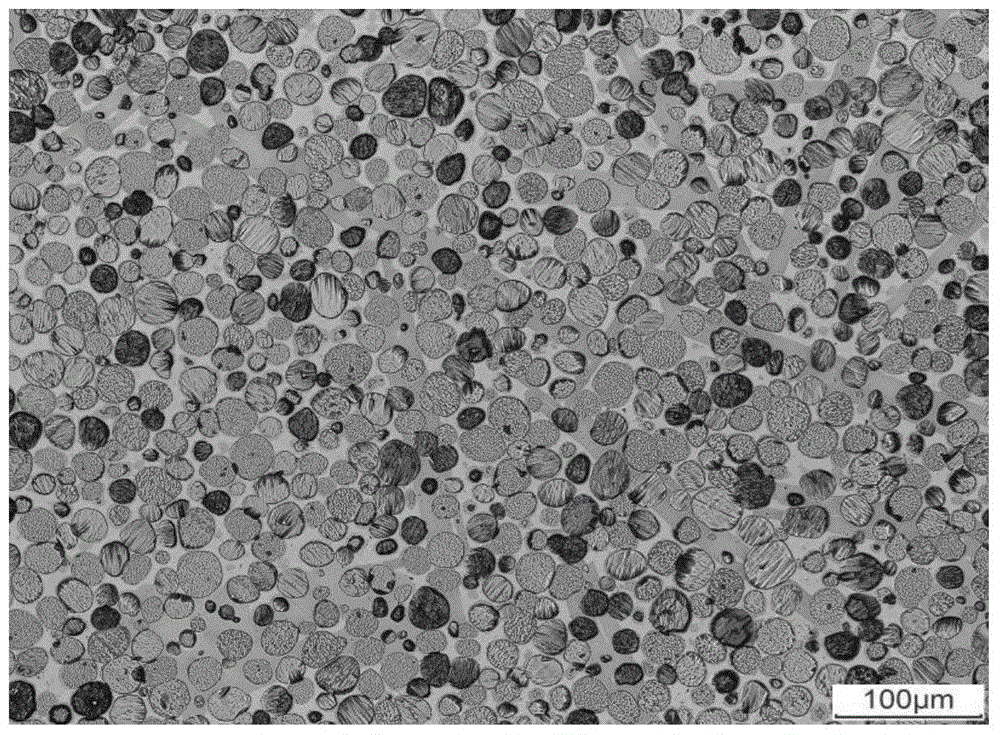

Embodiment 2

[0039] The preparation method of the fine-grained high-hardness tungsten-cobalt-nickel alloy of this embodiment comprises the following steps:

[0040] Step 1. Weigh tungsten powder, cobalt powder and nickel powder respectively by mass ratio W: Co: Ni=93: 3.5: 3.5; the Fischer particle size of the tungsten powder is 2.5 μm~3.5 μm, and the cost of the cobalt powder is The Fisherman's particle size is 1 μm to 2 μm, and the Fisherman's particle size of the nickel powder is 2.6 μm to 3.6 μm;

[0041] Step 2, adding the tungsten powder, cobalt powder and nickel powder weighed in step 1 into a mixer and mixing for 6 hours to obtain a mixed powder;

[0042] Step 3, using a cold isostatic press to press the mixed powder described in step 2 under a pressure of 150 MPa for 50 seconds to obtain a compact;

[0043] Step 4. Put the compact described in step 3 into a molybdenum wire pusher furnace, sinter at a temperature of 1540°C for 40 minutes to obtain a sintered compact, and then vacu...

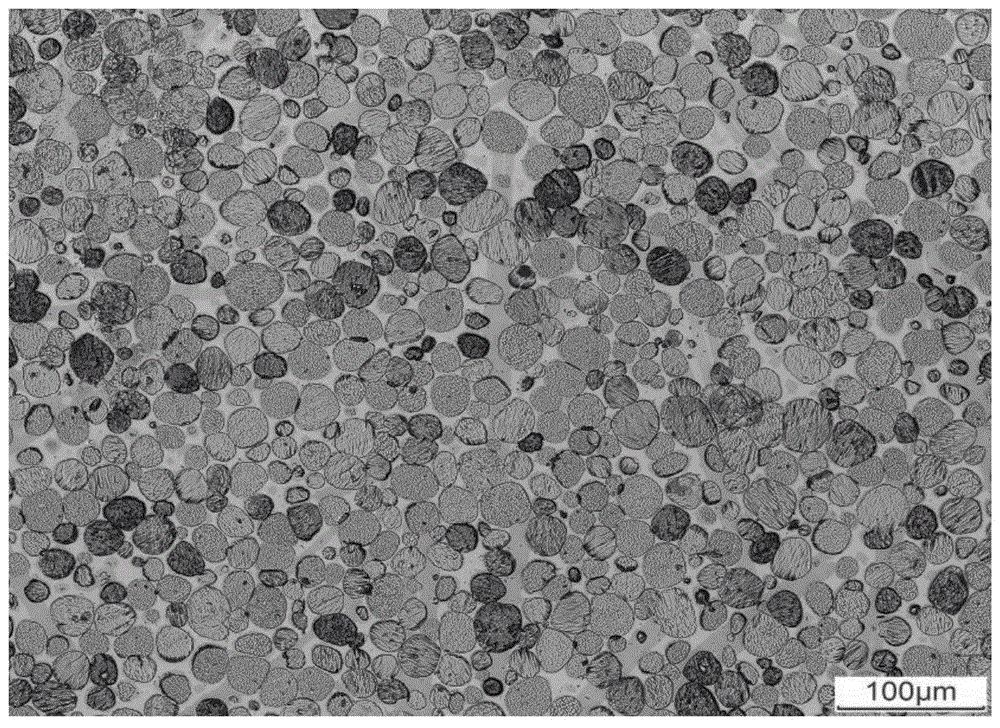

Embodiment 3

[0046] The preparation method of the fine-grained high-hardness tungsten-cobalt-nickel alloy of this embodiment comprises the following steps:

[0047] Step 1. Weigh tungsten powder, cobalt powder and nickel powder respectively by mass ratio W: Co: Ni=93: 3: 4; the Fischer particle size of the tungsten powder is 2.5 μm~3.5 μm, and the cost of the cobalt powder is The Fisherman's particle size is 1 μm to 2 μm, and the Fisherman's particle size of the nickel powder is 2.6 μm to 3.6 μm;

[0048] Step 2, adding the tungsten powder, cobalt powder and nickel powder weighed in step 1 into a mixer and mixing for 4 hours to obtain a mixed powder;

[0049] Step 3, using a cold isostatic press to press the mixed powder described in step 2 under a pressure of 140 MPa for 60 seconds to obtain a compact;

[0050] Step 4: Put the green compact described in step 3 into a molybdenum wire pusher furnace, sinter at a temperature of 1480°C for 30 minutes to obtain a sintered compact, and then va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com