A kind of crude extract of bacteriocin with antibacterial effect and its preparation method and application

A technology of antibacterial effect and bacteriocin, which is applied in the field of crude extract of bacteriocin and its preparation, can solve the problems of residual harmful metabolites of bacteria, poor stability of bacteriocin, high preparation cost, etc., and achieve extended food shelf life and optimal application The effect of stable value and nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

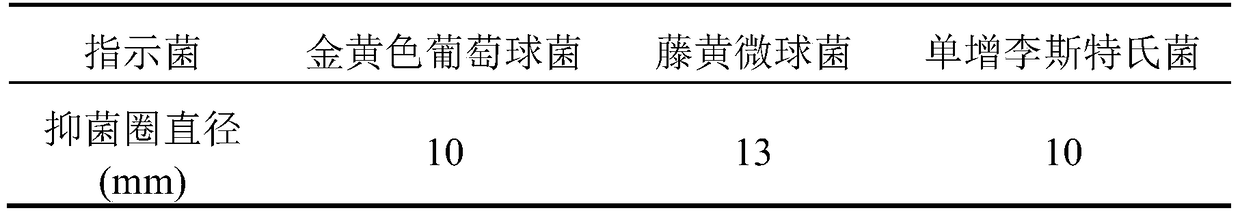

[0023] Example 1 Preparation of Paenibacillus Bacteriocin Crude Extract and Detection of Antibacterial Activity

[0024] 1. Materials and methods

[0025] Preparation of seeds (fermentation strains): freeze-drying of Paenibacillus sp. (the preservation number of Paenibacillus sp. is CGMCC No.8333, and the source of the strain is referred to the Chinese patent publication number CN103740618A). Dissolve the powder in a small amount of sterile distilled water, use an inoculation loop to draw a line on TYC solid medium (purchased from OXOID Co., UK), take it out after 48 hours of aerobic culture at 30°C, and use an inoculation loop to pick a single colony and put it into 10mL TYC Liquid culture medium (purchased from OXOID Co., UK), use a vortex shaker to evenly disperse the colonies in the liquid medium, take it out after 24 hours of shaking culture at 30°C and 180rpm, and inoculate it in TYC liquid culture with 2% (volume percentage) inoculum culture medium (purchased from OXOI...

Embodiment 2

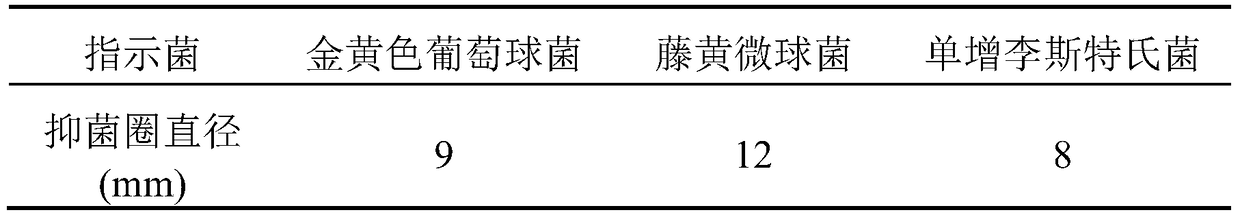

[0038] Example 2 Preparation of Paenibacillus Bacteriocin Crude Extract and Detection of Antibacterial Activity

[0039] 1, material and method: with embodiment 1.

[0040] 2. Preparation of Paenibacillus bacteriocin crude extract

[0041] Inoculate the Paenibacillus sp. CGMCC No.8333 strain into a sterile fermentation medium with an inoculum size of 1% (volume percentage), 37 ° C, 300 rpm shaking fermentation culture for 48 hours to obtain a fermentation liquid, and the above fermentation liquid 8 Centrifuge at 10,000rpm for 10min to take the precipitate, add acetone in an amount of 1 / 10 of the fermentation broth volume, vortex and mix, extract for 1 hour, extract 5 times, and then centrifuge at 10,000rpm for 10min to take the supernatant, evaporate in parallel to remove acetone, The bacteriocin crude extract B was obtained. Among them, the formula of the fermentation medium is: yeast extract 1%, casein hydrolyzate 2%, sucrose 1%, L-cystine 0.01%, sodium sulfate 0.03%, Na ...

Embodiment 3

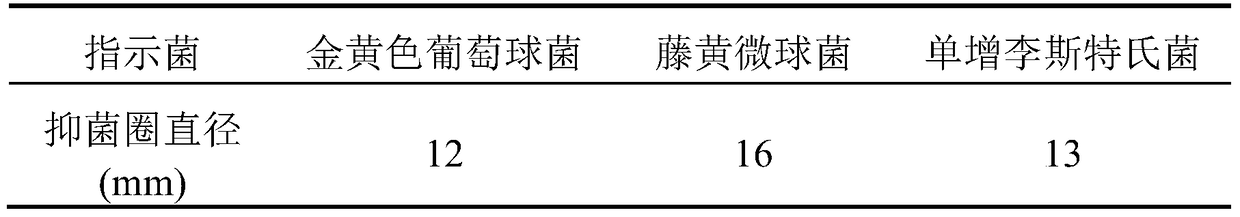

[0047] Example 3 Preparation of Paenibacillus Bacteriocin Crude Extract and Detection of Antibacterial Activity

[0048] 1, material and method: with embodiment 1.

[0049] 2. Preparation of Paenibacillus bacteriocin crude extract

[0050] Inoculate the Paenibacillus sp. CGMCC No.8333 strain into a sterile fermentation medium with an inoculum size of 2% (volume percentage), 30°C, 180rpm shaking fermentation culture for 30h to obtain a fermentation broth, and the above fermentation broth 8 Centrifuge at 15,000rpm for 5 minutes to take the precipitate, add acetone in an amount of 1 / 6 of the volume of the fermentation broth, vortex and mix, extract for 3 hours, and extract for 3 times, then centrifuge at 15,000rpm for 5 minutes to take the supernatant, and remove the acetone by rotary evaporation. The bacteriocin crude extract C was obtained. Among them, the formula of the fermentation medium is: yeast extract 0.5%, peptone 1.5%, sucrose 5%, L-cystine 0.02%, sodium sulfate 0.02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com