Air bag material for stratospheric airship and preparation method thereof

A stratospheric airship and air bag technology, applied in the field of aerospace materials, can solve the problems of increasing the surface density of the bag body material, reducing the load capacity, and reducing the cost performance, so as to reduce the difficulty of assembly work, ensure the load capacity, and improve the anti-static property. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

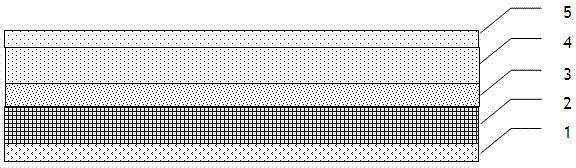

[0058] The invention provides a method for preparing an air bag material for a stratospheric airship, such as figure 1 As shown, it specifically includes the following steps:

[0059] Step (1), coating the antistatic layer (1) on one side of the support layer (2), curing at 100-140°C for 2-4 minutes;

[0060] Step (2), coating the surface of the gas barrier layer (4) with an adhesive layer (3), and drying at 50-70°C for 3-5 minutes;

[0061] Step (3), compounding the adhesive layer (3) with the side of the support layer (2) that is not coated with the antistatic layer (1), and then curing at 40-80°C for 36-72 hours;

[0062] Step (4), coating the antistatic layer (5) on one side of the polymer film of the gas barrier layer (4), and drying at 100-140°C for 2-4 minutes to obtain the antistatic layer (5), and obtain an antistatic layer (5). Electrostatically functional airbag material for stratospheric airships.

[0063] Compared with the common air bag material, the antistati...

Embodiment 1

[0065] Preparation of Antistatic Layer Coating Solution

[0066] Baytron P 23 with a solid content of 1.2%

[0067] Isopropanol 75

[0068] PU628 0.2

[0069] A-151 0.5

[0070] Dimethyl sulfoxide 0.8

[0071] C 4 f 9 SO 2 NH(CH 2 ) 5 OH 0.5

[0072] Under the conditions of avoiding sunlight or ultraviolet light and relative air humidity of less than 60%, add the above-mentioned substances into the mixing container in turn, stir each component for 15 minutes, filter to remove impurities, and obtain the coating for antistatic layer Cloth liquid N15.

[0073] The surface density is 25g / m 2 One side of the Vectran fiber cloth is coated with N15, and cured at 100°C for 4 minutes to obtain an antistatic layer 1 with a thickness of 1.0 microns;

[0074] Coat N15 on the PET surface of the gas barrier layer with a thickness of 12 microns, cure at 100°C for 4 minutes to obtain an antistatic layer 5 with a thickness of 0.5 microns, coat the other side with a polyurethane adh...

Embodiment 2

[0077] Preparation of coating solution for antistatic layer

[0078] Baytron P 14 with a solid content of 1.2%

[0079] Ethanol 83

[0080] SD-5 0.3

[0081] A-171 0.2

[0082] N-Methylpyrrolidone 1.5

[0083] C 8 f 17 CONH(CH 2 ) 2 OH 1

[0084] Under the conditions of avoiding sunlight or ultraviolet light and relative air humidity of less than 60%, add the above-mentioned substances into the mixing container in turn, stir each component for 15 minutes, filter to remove impurities, and obtain anti-static coating Liquid N15.

[0085] The surface density is 20g / m 2 One side of the Kevlar fiber cloth is coated with N15, cured at 120°C for 3 minutes, and the thickness is 1.4 microns;

[0086] Coat N15 on the surface of the 9-micron-thick gas barrier layer 4PEN, cure at 100°C for 4 minutes, and the thickness is 0.8 µm, coat the other side with a polyurethane adhesive layer, dry in an oven at 55°C for 3 minutes, and form a thickness of 15 µm the bonding layer;

[0087...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com