Container corrugated plate welding robot and visual servo control system thereof

A visual servo and control system technology, applied in the direction of digital control, welding equipment, welding equipment, etc., can solve the problems of high welding technology, affecting welding accuracy, easy water leakage, light leakage, etc., and achieve high intelligence, good welding quality, The effect of high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

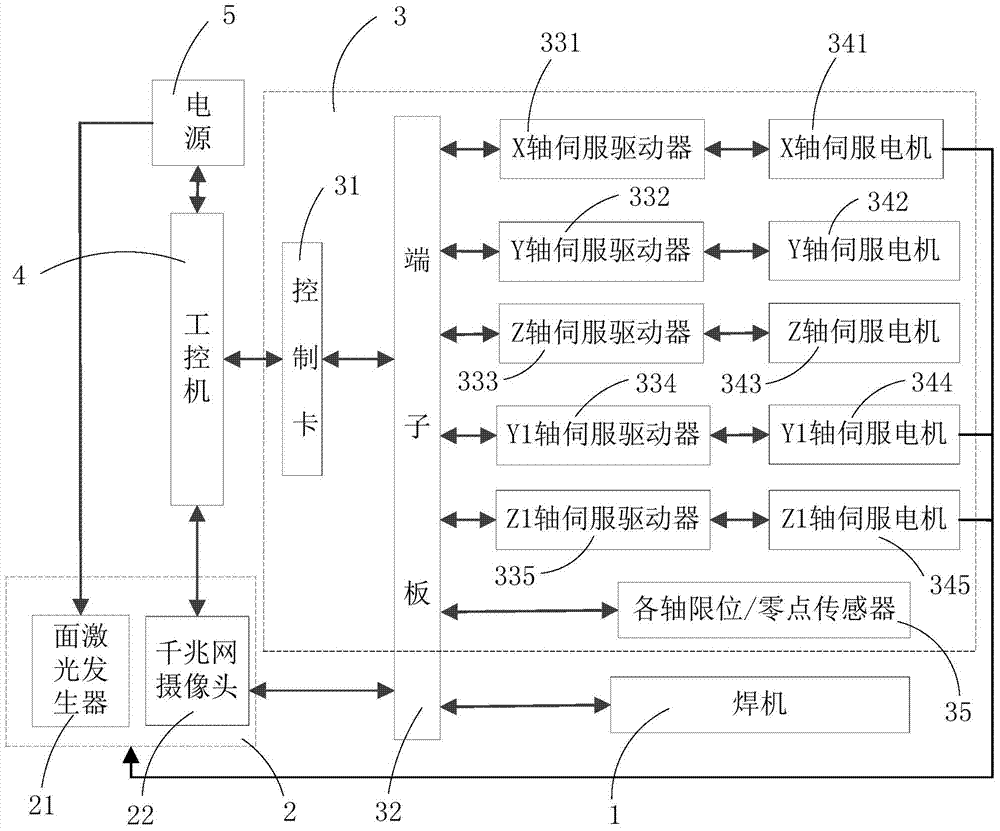

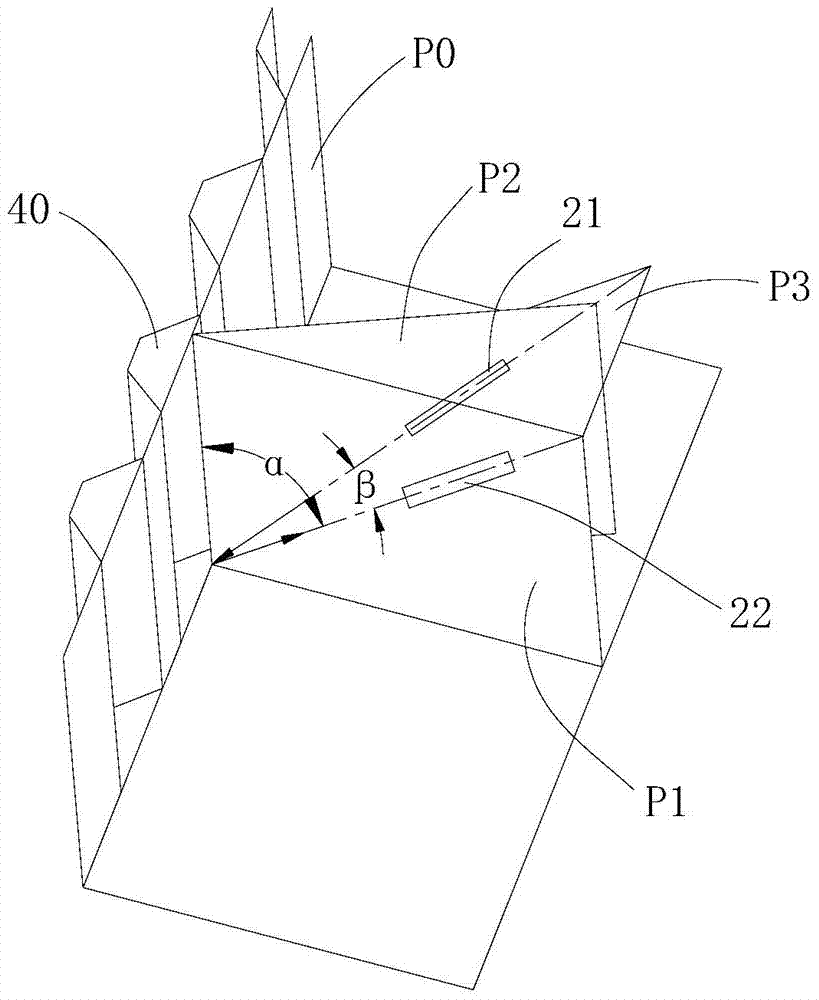

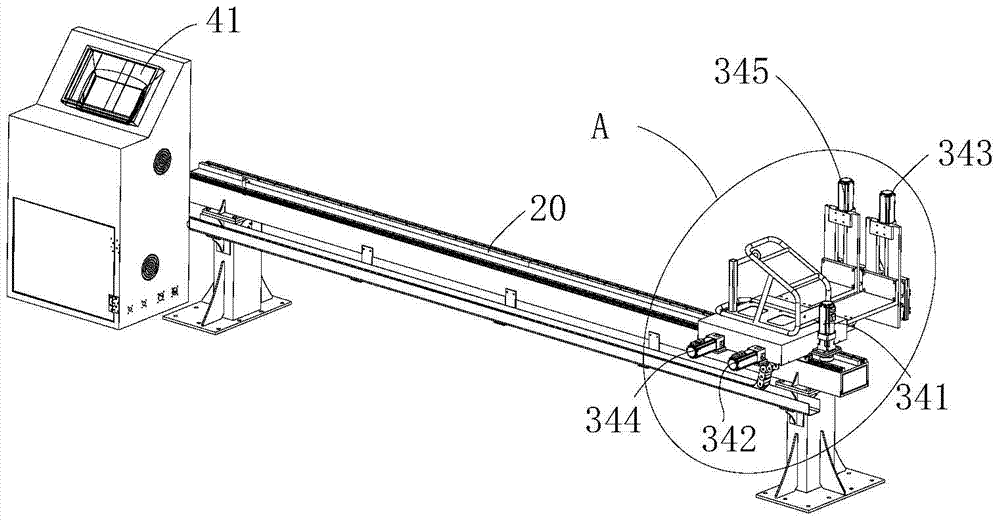

[0020] refer to figure 1 , the present invention provides a visual servo control system for corrugated plate welding of containers, the visual servo control system is mainly used for weld recognition and tracking control of corrugated plate welding, roughly composed of welding machine 1, visual sampling mechanism 2, motion The control mechanism 3, the industrial computer 4 and the power supply 5 are composed of five parts.

[0021] The welding machine 1 includes a welding power supply for providing welding current and voltage to the welding torch, a wire feeder for sending the welding wire to the weld seam and a shielding gas source for providing welding shielding gas; The machine 1 works with the set welding parameters to ensure the welding operation of the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com