Processing chamber and semiconductor processing equipment

A process chamber and reaction chamber technology, which is applied in semiconductor/solid-state device manufacturing, metal material coating process, ion implantation plating, etc. Small space, reduced manufacturing cost, compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

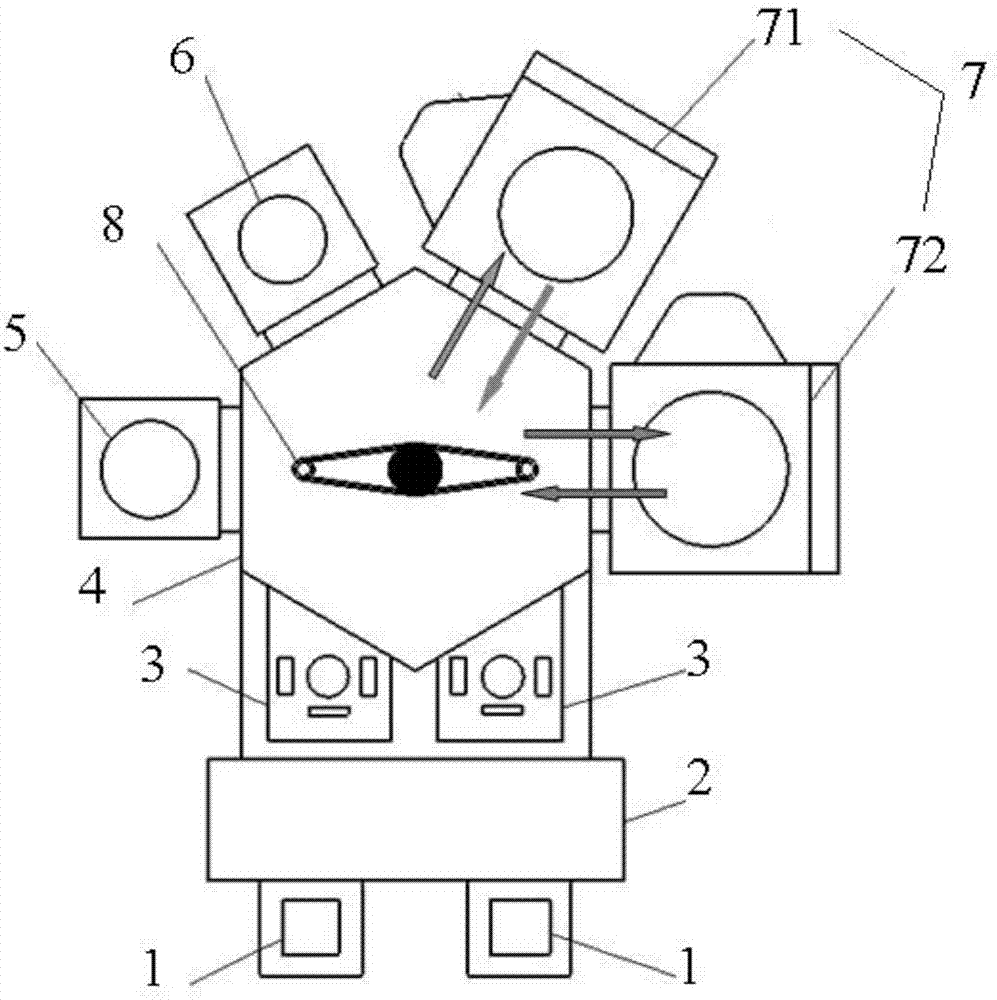

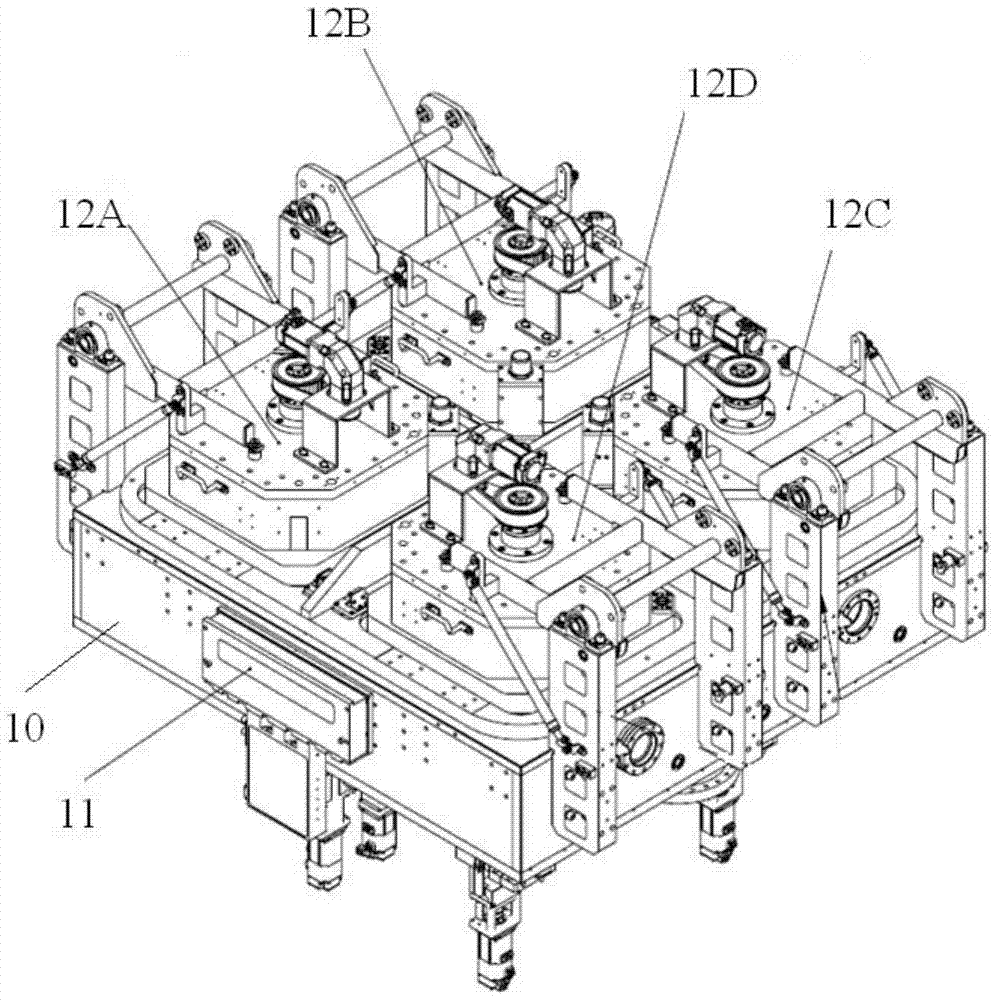

[0051] Please also refer to Figures 2A-2D , the process chamber 10 provided in this embodiment includes four reaction chambers, four sets of air intake systems and wafer transfer devices that are independent of each other. Wherein, the four reaction chambers are respectively: reaction chamber 12A, reaction chamber 12B, reaction chamber 12C and reaction chamber 12D, such as Figure 2A As shown, four reaction chambers are arranged inside the process chamber 10, and are evenly distributed along its circumference, and each reaction chamber constitutes an independent process environment, and utilizes four sets of air intake systems (not shown) one By correspondingly delivering process gases to the four reaction chambers and using the above-mentioned transport function of the wafer transport device, a single process chamber can simultaneously perform more than two processes.

[0052] In this embodiment, the structure of the wafer transfer device is as follows: it includes a rotati...

Embodiment 2

[0080] Compared with the first embodiment above, this embodiment differs only in that the structure of the wafer transfer device is different. Since other structures and functions of the process chamber provided in this embodiment have been described in detail in Embodiment 1 above, details will not be repeated here. In the following, only the structure of the wafer transfer device provided by this embodiment will be described in detail.

[0081] specifically, Figure 4A A perspective view of the internal structure of the process chamber provided for Embodiment 2 of the present invention. Figure 4B A top view of the internal structure of the process chamber provided by Embodiment 2 of the present invention. Please also refer to Figure 4A and Figure 4B , the wafer transfer device includes a manipulator 31 , a lifting base 13 and a thimble device 15 . Wherein, the number of lifting bases 13 corresponds to the number of reaction chambers, and the structure and function of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com