Biodegradable modified urea resin adhesive and application thereof

A urea-formaldehyde resin glue, biodegradable technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of reducing formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

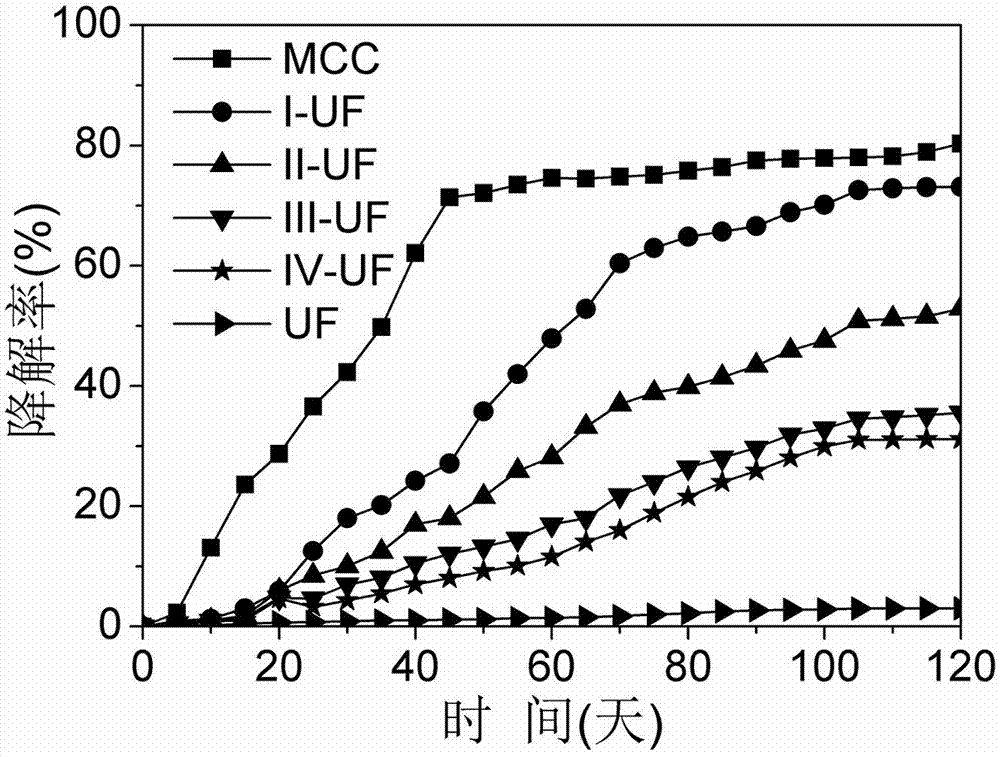

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of degradable modified urea-formaldehyde resin

[0026] (a) Add 702g of water into the reaction kettle, add 0.4g of KOH, heat to 70°C, add 105g of soybean protein isolate while stirring at a speed of 400rpm, then raise the temperature to 80°C, keep it warm for 1 hour, and obtain protein hydrolyzate, Then cool to 25°C;

[0027] (b) Add 117g of urea to the reaction kettle, stir and mix evenly, add formaldehyde solution, adjust the pH to 8.0 with KOH solution with a mass fraction of 20% at 25-30°C, then raise the temperature to 60°C, and add 87g of urea again , heat up to 90°C, and keep warm for 0.5h; slowly adjust the pH of the reaction solution to 4.5 with a mass fraction of 20% phosphoric acid solution, and continue to keep warm at 90°C until the reaction solution is dripped into 25-28°C water, and after white clouds are seen, The reaction is ended; adjust the pH of the reaction solution to 7.8 with KOH solution, then lower the temperature of the...

Embodiment 2

[0033] (a) Add 480g of water into the reaction kettle, add 1.1g of potassium hydroxide, and start heating. When heated to 70°C, add 72g of soybean protein isolate while heating rapidly to 80°C, and keep it warm for 1 hour to obtain protein hydrolyzate.

[0034] Step b, step c are identical with embodiment 1.

[0035] (d) Mix the block copolymer obtained in step b and the protein hydrolyzate obtained in step c uniformly at a mass ratio of 1:0.1 to obtain a biodegradable modified urea-formaldehyde resin adhesive

Embodiment 3

[0037] (a) Add 326g of water into the reaction kettle, add 1.3g of potassium hydroxide, and start heating. After heating to 70°C, add 48g of soybean protein isolate while stirring rapidly, keep heating to 80°C, and keep warm for 1 hour.

[0038] Step b, step c are identical with embodiment 1.

[0039](d) Mix the block copolymer obtained in step b and the protein hydrolyzate obtained in step c uniformly at a mass ratio of 1:0.3 to obtain a biodegradable modified urea-formaldehyde resin adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com