Preparation method of nanometer magnesia

A technology of nano-magnesium oxide and magnesium salt, which is applied in the direction of magnesium oxide, nanotechnology, nanotechnology, etc., can solve the problems of unfavorable promotion and utilization of nano-magnesia, poor agglomeration and purity, and poor performance of nanomaterials, and achieve favorable Effect of application and promotion, improvement of purity and dispersibility, performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of nano magnesium oxide, said method comprising the following steps:

[0043] 1) Weigh 11g of magnesium chloride hexahydrate, dissolve it in 100ml of ethylene glycol, and keep stirring to make it a transparent solution;

[0044] 2) Weigh 16g of urea, add it to the transparent solution, stir, and dissolve to obtain a mixed solution;

[0045] 3) Heat and stir the mixed solution under reflux, raise the temperature to 110° C., and react for 8 hours;

[0046] 4) After the reaction is completed, the resulting solution is cooled and aged for 10 hours;

[0047] 5) Dilute the solution obtained in step 4) with deionized water, filter with suction, wash the obtained precipitate twice with deionized water, and once with absolute ethanol to obtain a white precipitate, which is dried at 80°C for 4 hours, Cool to room temperature to obtain a white solid, which is calcined in a muffle furnace at 500°C for 3 hours to obtain nano-magnesia.

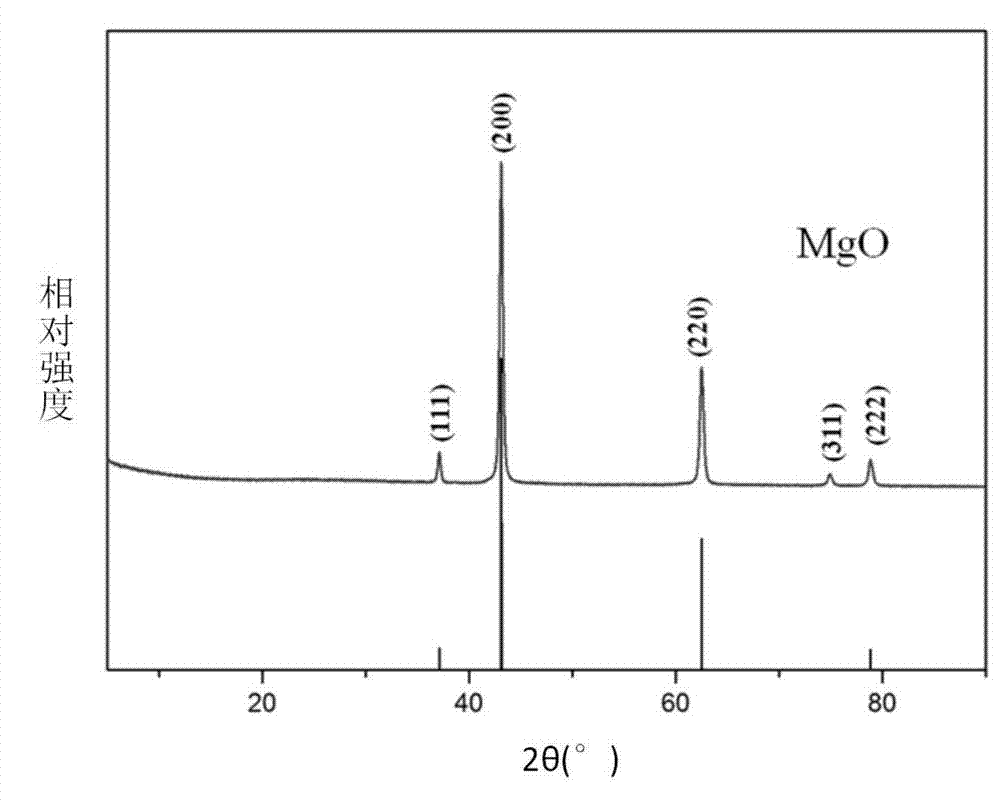

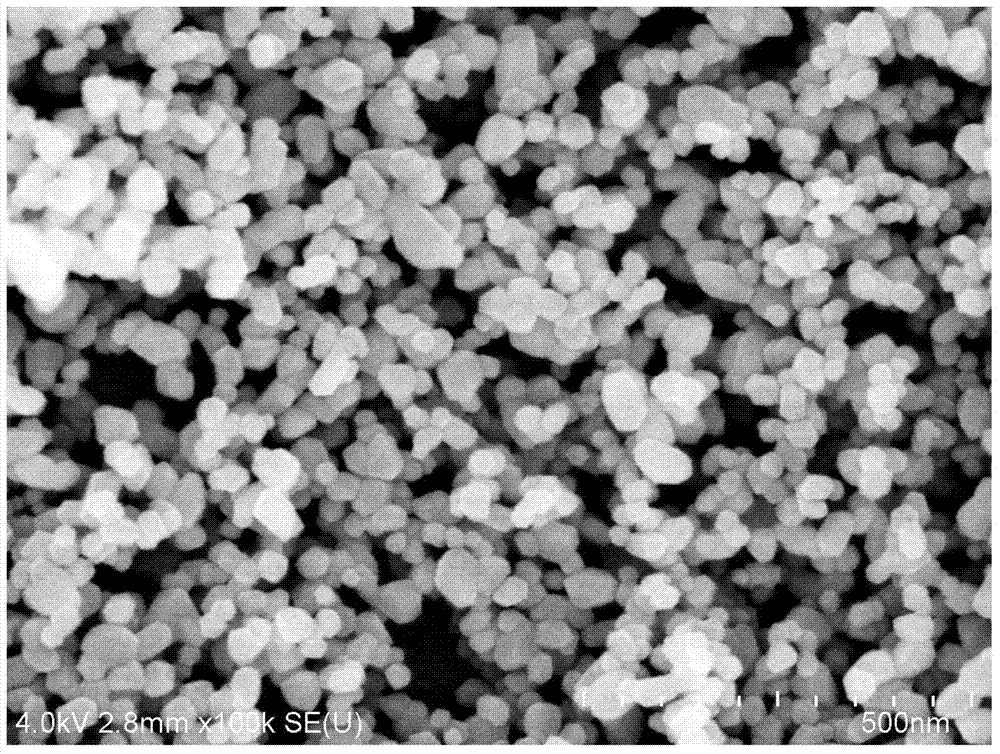

[0048] The nano magnes...

Embodiment 2

[0050] A preparation method of nano magnesium oxide, said method comprising the following steps:

[0051] 1) Weigh 11g of magnesium chloride hexahydrate, dissolve it in 100ml of ethylene glycol, and keep stirring to make it a transparent solution;

[0052] 2) Weigh 16g of ammonia water, add to the above-mentioned transparent solution, stir and dissolve to obtain a mixed solution;

[0053] 3) Heating and stirring the mixed solution under reflux, raising the temperature to 100° C., and reacting for 12 hours;

[0054] 4) After the reaction is completed, the resulting solution is cooled and aged for 10 hours;

[0055] 5) Dilute the solution obtained in step 4) with deionized water, filter with suction, wash the obtained precipitate twice with deionized water, and once with absolute ethanol to obtain a white precipitate, which is dried at 80°C for 4 hours, Cool to room temperature to obtain a white solid, which is calcined in a muffle furnace at 500°C for 3 hours to obtain nano-m...

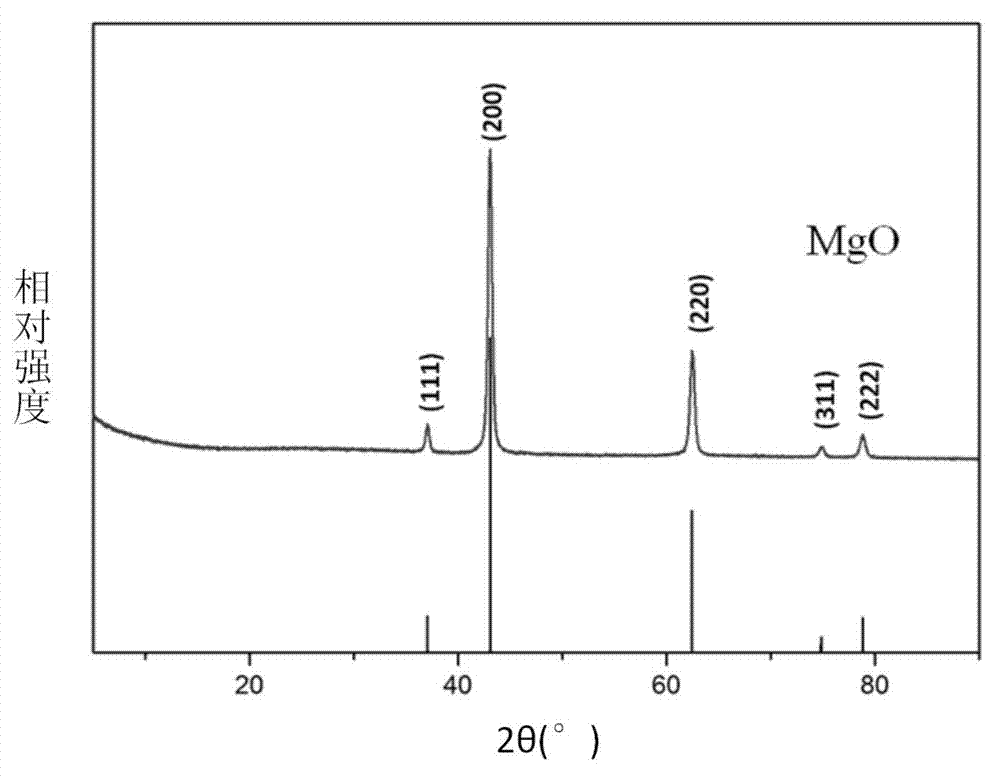

Embodiment 3

[0058] A preparation method of nano magnesium oxide, said method comprising the following steps:

[0059] 1) Take by weighing 11g of magnesium chloride hexahydrate, dissolve in 100ml of glycerol, and keep stirring to make it a transparent solution;

[0060] 2) Weigh 16g of ammonium carbonate, add in the above-mentioned transparent solution, stir, and dissolve to obtain a mixed solution;

[0061] 3) Heating and stirring the mixed solution under reflux, raising the temperature to 120° C., and reacting for 8 hours;

[0062]4) After the reaction is completed, the resulting solution is cooled and aged for 8 hours;

[0063] 5) Dilute the solution obtained in step 4) with deionized water, filter with suction, wash the obtained precipitate twice with deionized water, and once with absolute ethanol to obtain a white precipitate, which is dried at 80°C for 4 hours, Cool to room temperature to obtain a white solid, which is calcined in a muffle furnace at 500°C for 3 hours to obtain na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com