Equipment and process for producing crude hydrogen for hydrogenizing and refining petroleum product

A technology for hydrofining and petroleum products, which is applied in the fields of hydrogen, inorganic chemistry, non-metallic elements, etc., can solve the problems of difficulty in guaranteeing the stability of hydrofining of petroleum products, waste of methanol raw materials, and inability to modularize, so as to avoid hydrogen leakage , high utilization rate and low overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

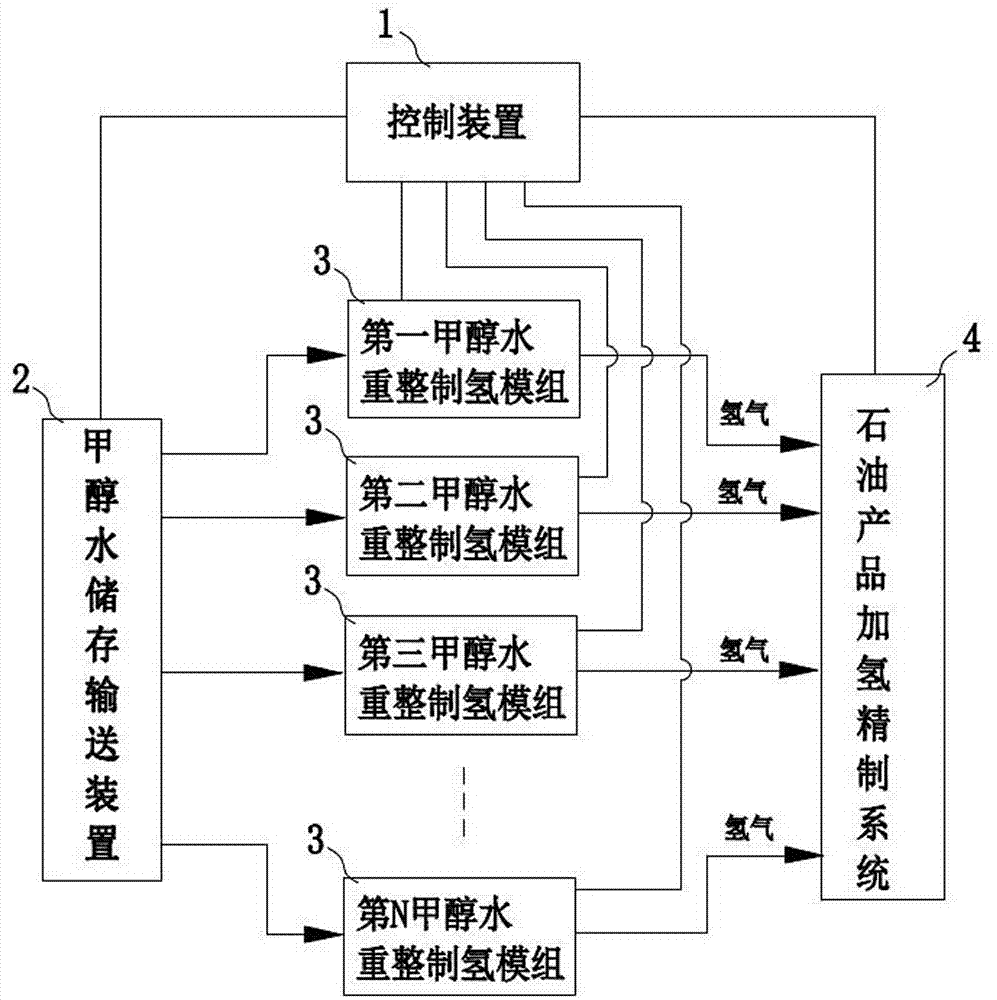

[0039] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] Such as Figure 9 Shown is a block diagram of the overall structure of the hydrofining system for petroleum products. Hydrogen and petroleum products enter the heating furnace 6 to be mixed and heated and then enter the reactor 7. Under the action of the catalyst in the reactor 7, the hydrofining reaction of petroleum products is carried out, including Desulfurization, denitrogenation, deoxygenation, hydrogenation saturation of olefins and aromatics, demetallization and other reactions; then, the reacted mixture is separated by the separator 8, and the unreacted hydrogen is compressed by the compressor 9 and returned to the input of the heating furnace 6, Restart the next hydrotreating reaction, and the refined petroleum products, waste gas and low-boiling hydrocarbons enter the stabilizing tower 10; af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com