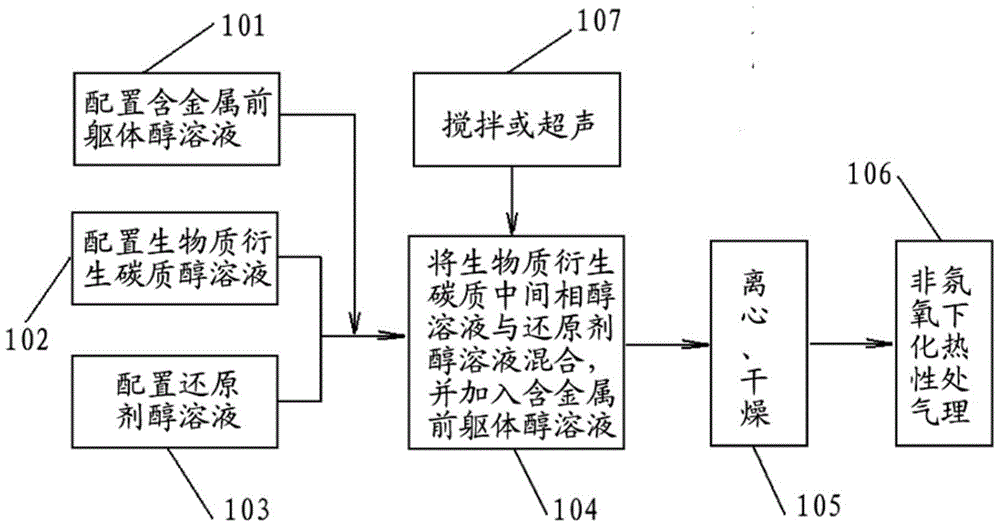

Electrical contact material and preparation method thereof

An electrical contact material and carbonaceous technology, applied in contacts, circuits, electric switches, etc., can solve the problem of poor bonding between the intermediate phase and metal powder, difficult control of the addition ratio of carbon materials, and poor performance stability of electrical contact materials. problem, to achieve the effect of improving arc erosion resistance, low cost, and controllable carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Weigh 0.1g of silver nitrate and dissolve it in 10ml of absolute ethanol to prepare an ethanol solution of silver nitrate;

[0038] (2) Weigh 0.12g of ascorbic acid and add it to 10ml of absolute ethanol, then add 2ml of ethanol solution of biomass-derived carbonaceous mesophase with a concentration of 0.001g / ml, and stir;

[0039] (3) Add the solution in step (1) dropwise to the solution in step (2), add 0.02g of ferric nitrate, stir and react at a constant temperature of 40°C for 10min, centrifuge and dry to collect the surface-coated biomass derived Composite micro-nano silver powder of carbonaceous mesophase film layer;

[0040] (4) The composite micro-nano silver powder obtained in step 3 was heat-treated in a pure hydrogen atmosphere at a temperature of 600°C for 2 hours, and the biomass-derived carbonaceous mesophase film on the surface of the silver powder was converted into a diamond-like film, and then subjected to conventional The contact material prepar...

Embodiment 2

[0042](1) Weigh 0.1g of silver nitrate and dissolve it in 10ml of absolute ethanol to prepare an ethanol solution of silver nitrate;

[0043] (2) Weigh 0.1g of ascorbic acid and add it to 10ml of absolute ethanol, then add 2ml of ethanol solution of biomass-derived carbonaceous mesophase with a concentration of 0.01g / ml, and stir;

[0044] (3) Add the solution in step (1) to the solution in step (2) drop by drop, add 0.03g of nickel nitrate, and react with ultrasonic assistance at a constant temperature of 40°C for 30 minutes, centrifuge and dry to collect the surface-coated organic Composite micro-nano silver powder derived from material-derived carbonaceous mesophase film layer;

[0045] (4) The composite micro-nano silver powder obtained in step 3 was heat-treated in a pure hydrogen atmosphere at a temperature of 800°C for 6 hours, and the biomass-derived carbonaceous mesophase film on the surface of the silver powder was converted into a diamond-like film, and then subject...

Embodiment 3

[0047] (1) Weigh 0.01g of silver nitrate and dissolve it in 10ml of isopropanol to prepare an alcohol solution of silver nitrate;

[0048] (2) Weigh 0.012g of glucose and add it to 10ml of isopropanol, then add 1ml of isopropanol solution of biomass-derived carbonaceous mesophase with a concentration of 0.002g / ml, and stir;

[0049] (3) Add the solution in step (1) drop by drop to the solution in step (2), add 0.02g of cobalt nitrate, react at a constant temperature of 20°C for 1 hour, centrifuge and dry to collect biomass coated on the surface Composite micro-nano silver powder derived from carbonaceous mesophase film layer;

[0050] (4) heat-treat the composite micro-nano silver powder obtained in step 3 under a hydrogen-nitrogen mixed gas atmosphere at a temperature of 900°C for 2 hours, and the biomass-derived carbonaceous mesophase film on the surface of the silver powder is converted into a diamond-like film, After the conventional contact material preparation process, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com