Flexible fluororesin cable for multifunctional compound machine

A compound machine, fluororesin technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problem of insufficient heat resistance, oil resistance, oxidation resistance, chemical resistance, low temperature resistance, friction resistance, softness There are problems such as lack and lack of existence, to achieve ideal high and low temperature resistance, convenient repeated twists and turns, and to meet the effect of wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

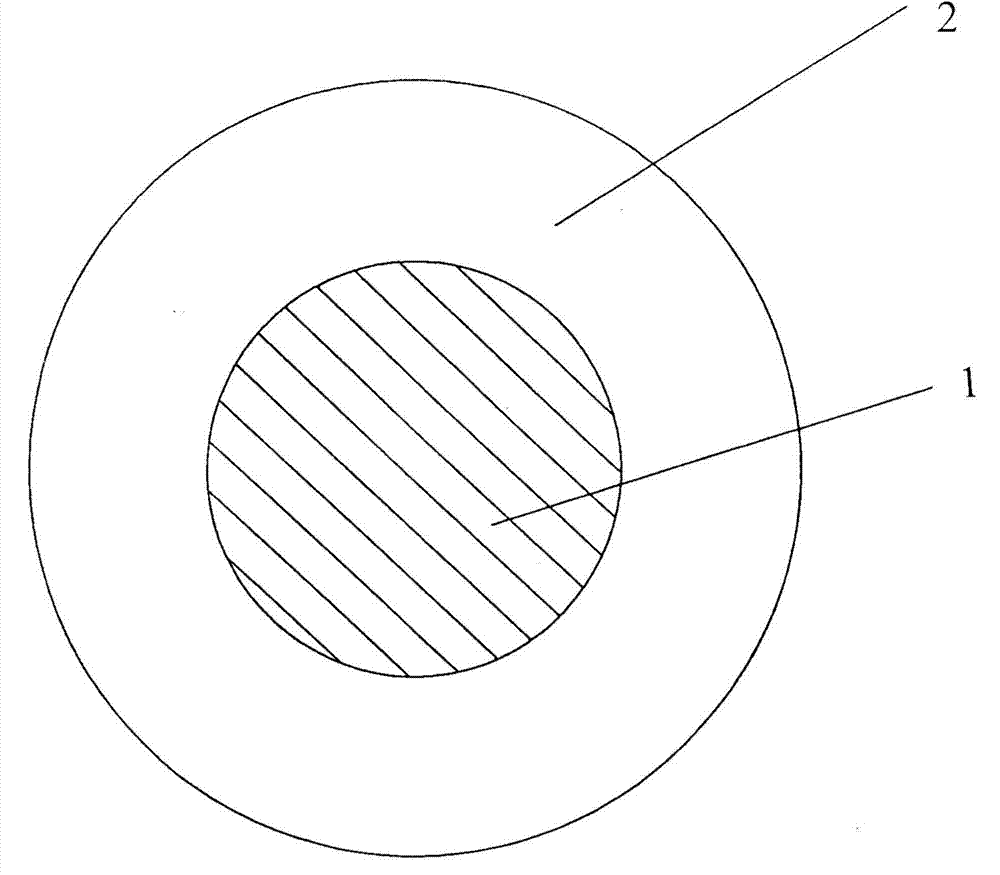

[0014] See figure 1 , a conductor 1 and an insulating layer 2 extruded on the outside of the conductor 1 in the form of an extruded sheath are given. As the technical point of the technical solution provided by the present invention, the conductor 1 is made of a plurality of hot-dip tin Copper wires (also called hot-dip tinned thin copper wires, the same below) are twisted, and the insulating layer 2 is a fluororesin layer with a thickness of 0.75mm. Since the conductor 1 is made of twisted hot-tinned copper wires with hot-tinned surface, its concentricity is very ideal, which ensures the concentricity of the insulating layer 2 acted by the fluororesin layer, that is, there is no eccentricity in the insulating layer 2, and no Withstand voltage breakdown may occur due to eccentricity (uneven wall thickness) of the insulating layer 2. In addition, the use of hot-dip tinned copper wire can significantly improve the oxidation resistance of the surface of the conductor 1 , and no ...

Embodiment 2

[0016] Only change the diameter of the hot-dip tinned copper wire to 0.05mm, and change the thickness of the insulating layer 2 to 0.12mm, and the rest are the same as the description of embodiment 1.

Embodiment 3

[0018] Only change the diameter of the hot-dip tinned copper wire to 0.5mm, and change the thickness of the insulating layer 2 to 1.5mm, and the rest are the same as the description of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com