Method for producing high-quality gasoline/diesel from chlorine-containing plastic oil

A plastic oil, high-quality technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., to achieve the effect of resource utilization, improve selectivity, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

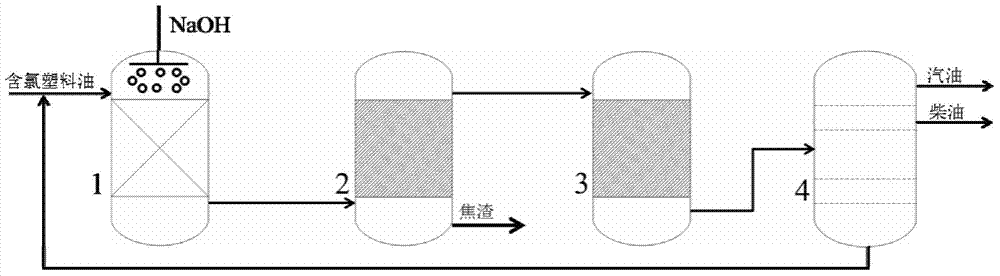

Method used

Image

Examples

Embodiment 1

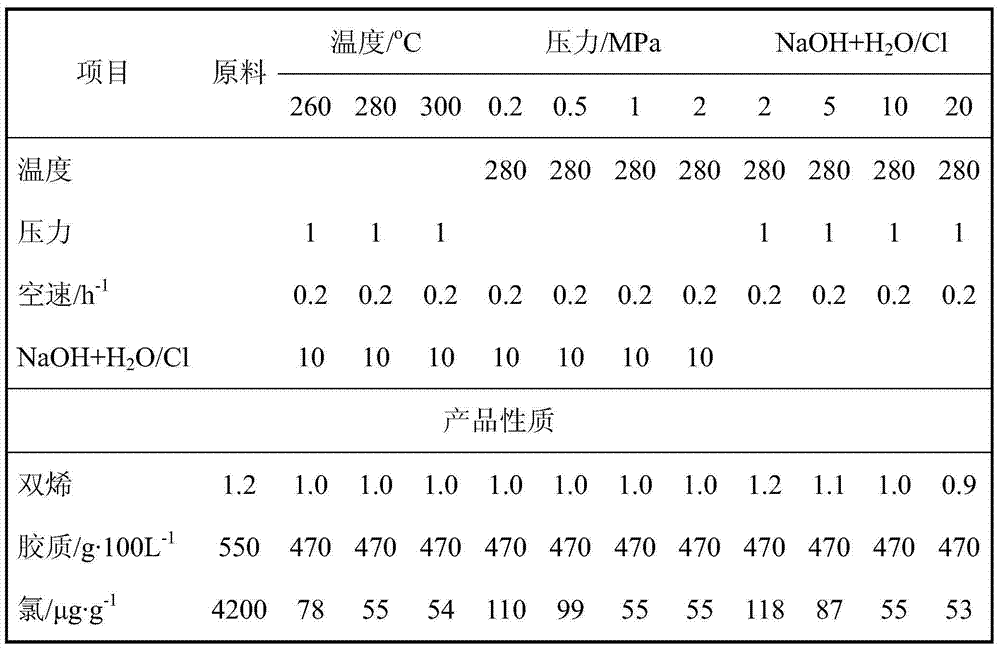

[0019] The chlorine-containing plastic oil is injected into the high-temperature dechlorination tower for high-temperature dechlorination. The catalyst is modified active aluminum oxide and a small amount of Y-type zeolite, the content of the Y-type zeolite is 0.05%-0.1%, and the molded catalyst is obtained by extruding and forming, and the bulk density is 0.82g / mL. The following table 1 sees the reaction process conditions and product properties.

[0020]

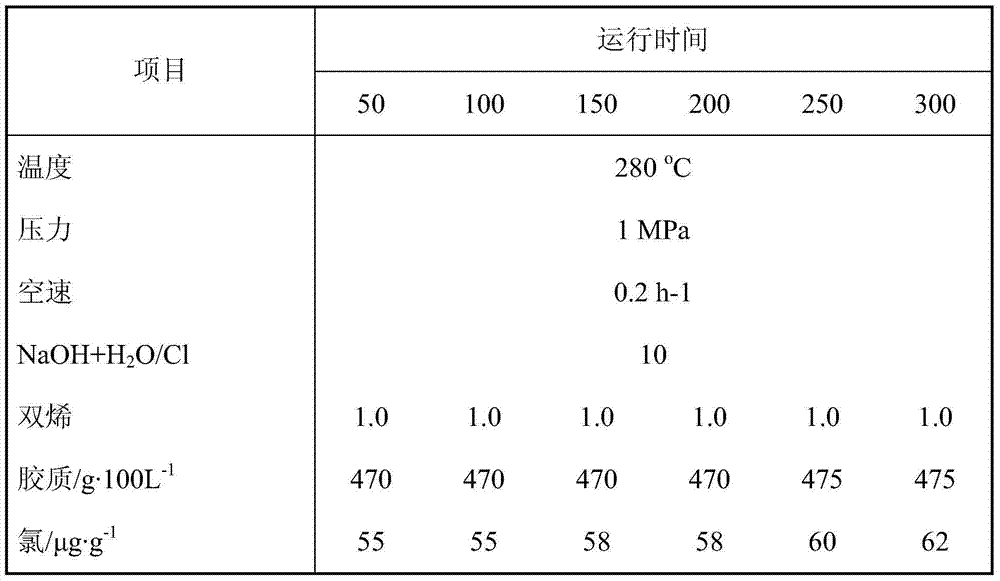

[0021] It can be seen from the table that when the reaction exceeds 280°C and the pressure exceeds 1MPa, NaOH+H 2 The dechlorination effect is not obvious when the O / Cl ratio is greater than 10, so the reaction conditions are: 280°C, 1MPa, NaOH+H 2 The life experiment was done under the condition of O / Cl 10. The following table 2 sees the reaction process condition of 300 hours operation and the product property that finally obtains.

[0022]

[0023] It can be seen from Table 2 that the experimental results for 3...

Embodiment 2

[0025] Gas-phase catalytic cracking of plastic oil after dechlorination over a molecular sieve / alumina catalyst. The dechlorinated plastic oil is injected into the reactive distillation tower equipped with molecular sieve / alumina catalyst for reaction and distillation. The catalyst is composed of alumina containing 15% ZSM-5 and 35% zeolite beta, formed by bonding A columnar product of 2.0-3.0mm is obtained, the length is 3-8mm, the bulk density is 0.75g / mL, and the strength is greater than 40N / mm. The waste residue and gas generated during the waste plastic oil conversion process are used for heating, and the ratio of agent to oil is controlled at 15-20. See Table 3 below for the results of the catalytic distillation material balance test.

[0026]

[0027] See Table 4 below for properties of catalytic distillation chlorine-containing plastic oil

[0028]

[0029] It can be seen from Table 4 that after catalytic distillation of chlorine-containing plastic oil, the sul...

Embodiment 3

[0031] Taking the supported NiMo sulfide catalyst as an example, the effects of temperature and pressure on the effect of hydrodechlorination were investigated. The carrier adopts SiO 2 -Al 2 o 3 , the specific surface area is 200-400m 2 / g, the pore volume is 0.5-2.0cm 3 / g, the most probable pore size distribution is 2-4nm and 10-15nm. The supported sulfide catalyst is prepared through the steps of impregnation-drying-calcination and the like by adopting an equal-volume impregnation method. The loading amount of metal Ni was 5%, and the loading amount of metal Mo was 20%. The following table 5 sees NiMo sulfide catalyst reaction process conditions and product properties.

[0032]

[0033] It can be seen from Table 5 that the reaction temperature has little effect on the dechlorination effect, but has a significant effect on the desulfurization and denitrification effect; while the reaction pressure has little effect on the hydrodesulfurization, denitrification and de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com