A kind of hydantoin type epoxy resin toughening agent and preparation method thereof

A technology of hydantoin epoxy resin and epoxy resin, applied in the field of toughening agent, can solve the problems of loss of application value, decrease of temperature resistance, difficulty in processing, etc., to eliminate cracking phenomenon, improve impact strength, and have environmental protection Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

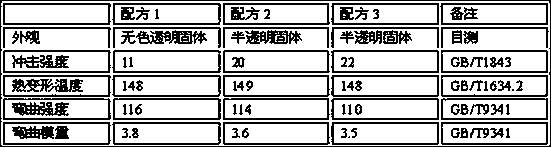

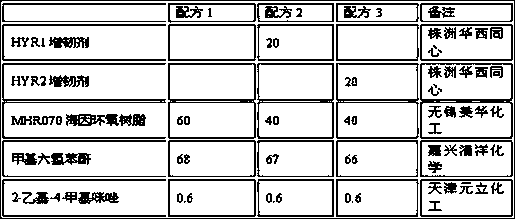

[0016] According to the above design scheme, two toughening agent products, HYR1 and HYR2, are now prepared, and the formulas of the examples are shown in Table 1.

[0017] Table 1 Hydantoin type epoxy resin toughening agent embodiment formula

[0018]

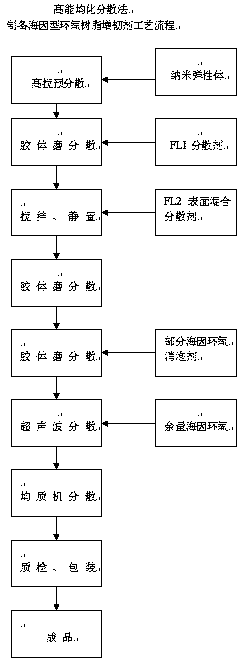

[0019] The processing flow of Hein type epoxy resin toughening agent is divided into eight steps in detail, as follows:

[0020] Step 1. Pre-dispersion: Put the nano-elastic particles in the dispersion container, add FL-1 composite lubricating dispersant, stir with a high-speed mixer at a speed of 4000r / min for 25 minutes, and keep the temperature at 25°C~45°C;

[0021] Step 2, fine dispersion: transfer the material obtained in step 1 into a colloid mill, grind twice, and keep the temperature at 25°C~45°C;

[0022] Step 3, soaking and coating: transfer the material obtained in step 2 into a dispersion container, add FL-2 active surface treatment agent, stir with a high-speed mixer at a speed of 100r / min for 120 minutes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com