A kind of method for preparing melamine molecularly imprinted polymer by distillation precipitation polymerization

A technology of distillation precipitation polymerization and melamine, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of complex polymer components, etc., and achieve the effect of simple operation and easy control of preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

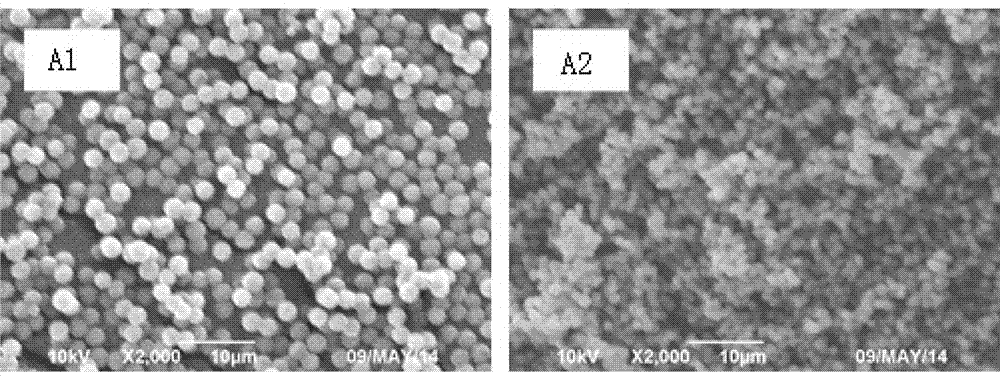

[0028] Synthesis I of embodiment 1 MEL imprinted polymer

[0029] Dissolve 0.22 g of melamine (MEL), 0.60 mL of methacrylic acid, and 5.0 mL of divinylbenzene in 80 mL of acetonitrile, sonicate for 2 min to mix them evenly, and place them in a three-necked flask after standing in the dark for 12 h, then add Azobisisobutyronitrile 0.13 g, deoxygenated by argon for 5 minutes, stirred at a speed of 120 r / min and heated in a water bath at room temperature, heated to the boiling point of acetonitrile within about 30 minutes, and distillate was collected at this time. By controlling the temperature, the reaction was terminated when 40 mL of acetonitrile was evaporated within 1.5 to 2 h. The emulsion obtained by polymerization was ultrasonically and suction-filtered, and the filter residue was washed with methanol three times, then extracted in a Soxhlet extractor with methanol-acetic acid (9:1, v / v) for 24 h, and then rinsed with methanol Several times, drying in an oven at 50 ℃ to...

Embodiment 2

[0032] Example 2 Synthesis II of MEL imprinted polymer

[0033] The amount of methacrylic acid is 0.43 mL, the amount of divinylbenzene is 3.57 mL, other conditions are the same as in Example 1, and the obtained polymer is as follows image 3 Shown (B1 is MIPs, B2 is NIPs).

Embodiment 3

[0034] Example 3 Synthesis of MEL imprinted polymer III

[0035] Dissolve 0.22 g of melamine (MEL), 0.80 mL of methyl methacrylate, and 5.0 mL of divinylbenzene in 80 mL of acetonitrile, sonicate for 2 min to mix them evenly, and place them in a three-necked flask after standing in the dark for 12 h. Then add 0.19 g of benzoyl peroxide, pass through argon gas for deoxygenation for 5 minutes, stir at a speed of 120 r / min, start heating in a water bath at room temperature, and heat to the boiling point of acetonitrile within about 30 minutes. At this time, start to collect distillate. By controlling the temperature, the reaction was terminated when 40 mL of acetonitrile was evaporated within 1.5 to 2 h. Other conditions are with embodiment 1. The maximum binding capacity of the MEL imprinted polymer is 32.75 mg / g (the test method is the same as in Example 4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com