Making method for physical anti-scaling nanocomposite ceramic ball particles

A technology of nano-composite materials and ceramic balls, applied in the field of physical scale prevention, can solve problems such as serious water consumption, high operating costs, and environmental pollution, and achieve the effects of low cost, simple manufacturing process, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

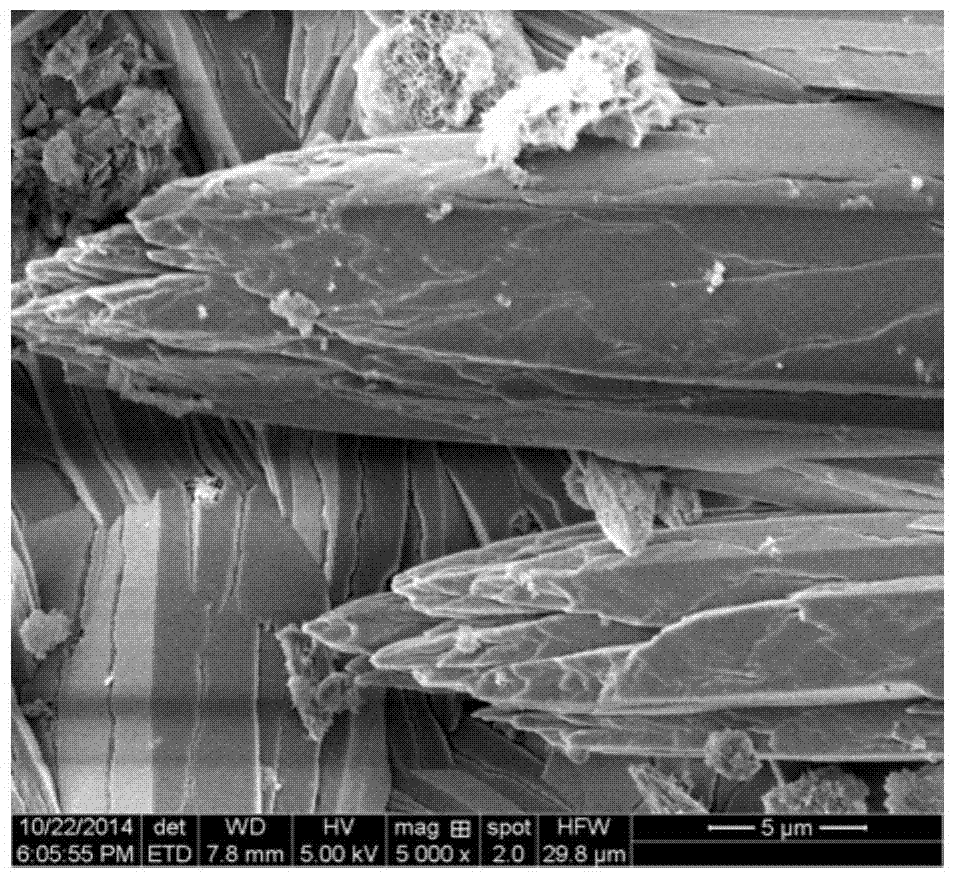

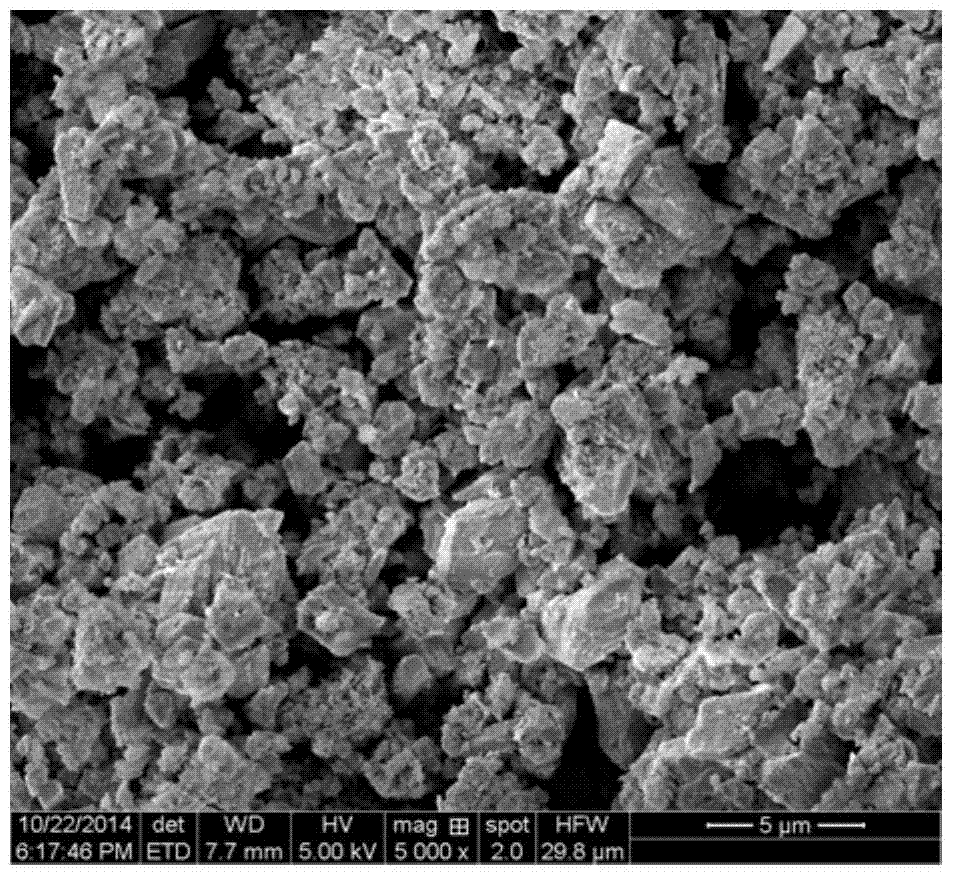

Image

Examples

Embodiment 1

[0027] A kind of nanocomposite ceramic spheres of physical antifouling, wherein the composition and parts by weight are as follows:

[0028] 45 parts of tourmaline (the iron content of the tourmaline is less than 1.5%); 30 parts of kaolin; 5 parts of light rare earth (containing La element, Ce element, Nd element); 20 parts of copper-zinc alloy (containing 15- 40% Cu, 2.5-30% Zn, 2.5-8% Ni, 2.5-8% Sn).

[0029] A method for preparing a physically antifouling nanocomposite ceramic sphere, comprising the following steps:

[0030] 1) prepare the following materials by weight:

[0031] 45 parts of tourmaline (the iron content of the tourmaline is less than 1.5%); 30 parts of kaolin; 5 parts of light rare earth (containing La element, Ce element, Nd element); 20 parts of copper-zinc alloy (containing 15- 40% Cu, 2.5-30% Zn, 2.5-8% Ni, 2.5-8% Sn);

[0032] 2) powders that are processed into said materials respectively:

[0033] The particle size of tourmaline powder is 900nm, th...

Embodiment 2

[0038] A kind of nanocomposite ceramic spheres of physical antifouling, wherein the composition and parts by weight are as follows:

[0039] 55 parts of tourmaline (the iron content of the tourmaline is less than 1.5%); 10 parts of kaolin; 8 parts of light rare earth (containing La element, Ce element, Nd element); 27 parts of copper-zinc alloy (containing 15- 40% Cu, 2.5-30% Zn, 2.5-8% Ni, 2.5-8% Sn).

[0040] A method for preparing a physically antifouling nanocomposite ceramic sphere, comprising the following steps:

[0041] 1) The first step, prepare the following materials by weight:

[0042] 55 parts of tourmaline (the iron content of the tourmaline is less than 1.5%); 10 parts of kaolin; 8 parts of light rare earth (containing La element, Ce element, Nd element); 27 parts of copper-zinc alloy (containing 15- 40% Cu, 2.5-30% Zn, 2.5-8% Ni, 2.5-8% Sn);

[0043] 2) powders processed from the materials respectively: the particle size of tourmaline powder is 400nm, the pa...

Embodiment 3

[0048] A kind of nanocomposite ceramic spheres of physical antifouling, wherein the composition and parts by weight are as follows:

[0049] 45 parts of tourmaline (the iron content of the tourmaline is less than 1.5%); 35 parts of kaolin; 5 parts of light rare earth (containing La element, Ce element, Nd element); 15 parts of copper-zinc alloy (containing 15- 40% Cu, 2.5-30% Zn, 2.5-8% Ni, 2.5-8% Sn).

[0050] A method for preparing a physically antifouling nanocomposite ceramic sphere, comprising the following steps:

[0051] 1) The first step, prepare the following materials by weight:

[0052]45 parts of tourmaline (the iron content of the tourmaline is less than 1.5%); 35 parts of kaolin; 5 parts of light rare earth (containing La element, Ce element, Nd element); 15 parts of copper-zinc alloy (containing 15- 40% Cu, 2.5-30% Zn, 2.5-8% Ni, 2.5-8% Sn);

[0053] 2) powders processed from the materials respectively: the particle size of tourmaline powder is 100nm, the par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com