System and method for controlling hydraulic tension of straight-pull cold rolling experiment machine

A tension control and hydraulic tension technology, applied in tension/pressure control, fluid pressure actuating devices, mechanical equipment, etc., can solve the difficulty, uncertainty, and lack of robustness in high-precision prediction of forward slip rate and rear slip rate. Strong and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

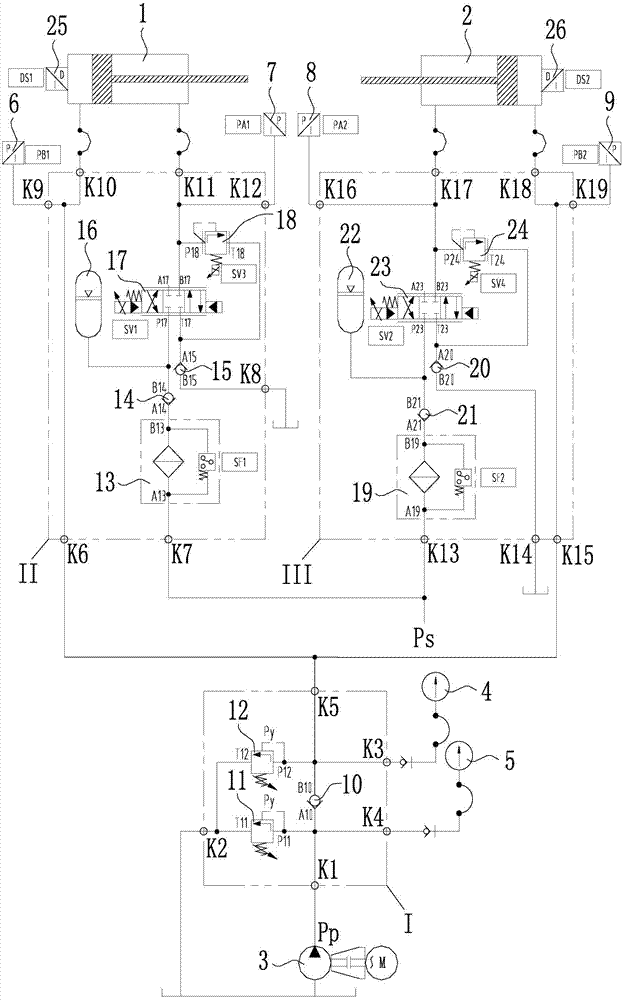

[0063] Such as figure 1 As shown, a hydraulic tension control system for a straight-pull cold rolling test machine, including a left tension hydraulic cylinder 1, a right tension hydraulic cylinder 2, a hydraulic pump 3, a constant back pressure control unit I, a left tension control unit II and a right tension control unit Unit III;

[0064] The oil inlet K1 of the constant back pressure control unit 1 is connected with the oil outlet Pp of the hydraulic pump 3, and the oil return port K2 of the constant back pressure control unit 1 is connected with the oil supply tank of the hydraulic pump 3; The constant back pressure control unit 1 is also provided with a first pressure measuring port K3 and a second pressure measuring port K4, the first pressure measuring port K3 is connected with a first pressure gauge 4, and the second pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com