A piling method for wharf based on crawler construction machinery

A kind of engineering machinery and crawler-type technology, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of extended construction period, low economic benefit, and reduced pile foundation stability, so as to ensure the construction period and construction quality, and design methods Simple, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

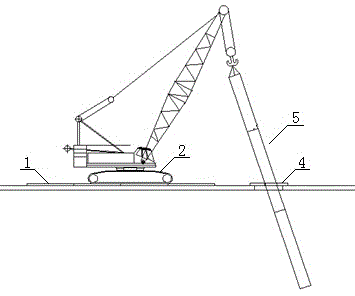

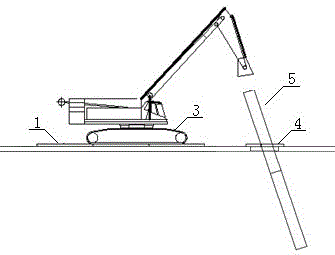

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] A kind of wharf piling method based on crawler-type engineering machinery designed by the present invention is specifically implemented through the following steps in the actual application process:

[0033] Step 001. According to the construction design, measure the pile foundation construction position on the ground of the wharf to be constructed, and mark the axis control point on the ground of the wharf to be constructed according to the construction position of the pile foundation, and enter step 002.

[0034] Step 002. Drill holes at the pile foundation construction positions to obtain through holes and penetrate through the ground of the wharf to be constructed, and proceed to step 003.

[0035] Step 003. Lay steel plates on the ground of the wharf to be constructed adjacent to the construction position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com