Plastic masterbatch and manufacturing method thereof

A plastic masterbatch and plastic technology, applied in the field of plastic masterbatch and its manufacturing, can solve the problems of pseudomyopia, damage to photoreceptor cells, lack of nutrients in photosensitive cells, etc., and achieve the effect of uniform diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable your examiner to clearly understand the content of the present invention, only the following descriptions are provided together with the accompanying drawings, please refer to them.

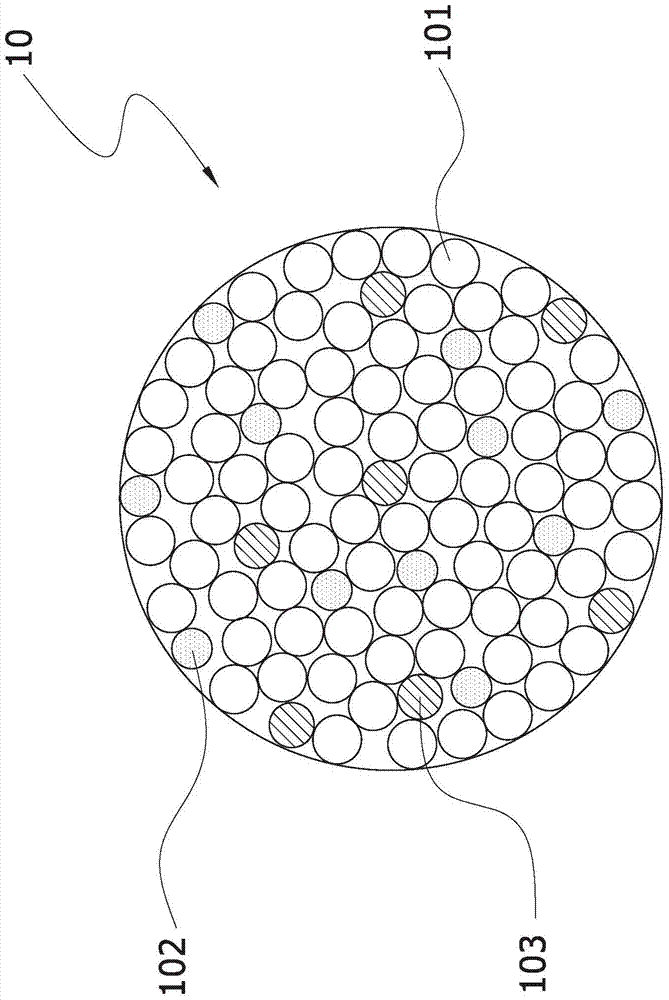

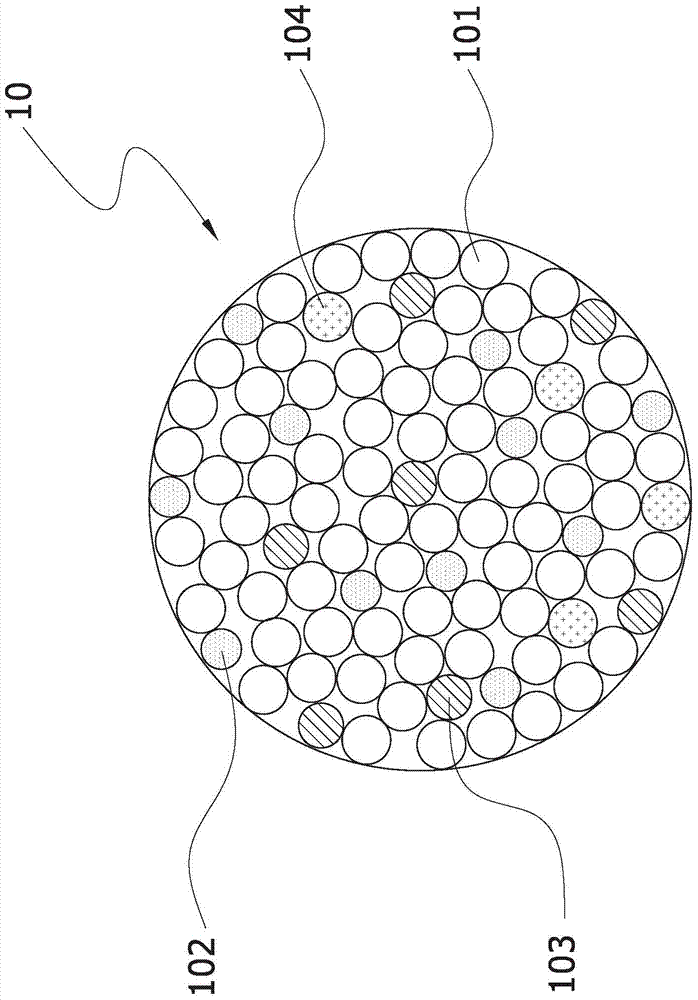

[0027] see figure 1 , is a schematic diagram of the composition of the plastic masterbatch of the present invention, a plastic masterbatch 10 as shown in the figure, which is mainly composed of plastic powder 101, light diffusion powder 102 and anti-blue light powder 103, wherein, Plastic powder 101 (also called plastic particles with small particle size) is a high molecular polymer, which is the main raw material for finished plastic products. According to the physical and chemical properties of material molecules, it can be divided into thermoplastics (Thermoplastics) plastics) and thermosetting plastics (Thermoset plastics), among them, those that become fluid after heating and then become solid after cooling are thermoplastics, which can be repeatedly processed and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com