An upward flow circular oil separation pretreatment device

A pretreatment device, circular technology, applied in the direction of grease/oily substance/float removal device, water/sewage treatment, water/sewage treatment equipment, etc. It can achieve the effect of small footprint, simple operation and maintenance, and low equipment operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

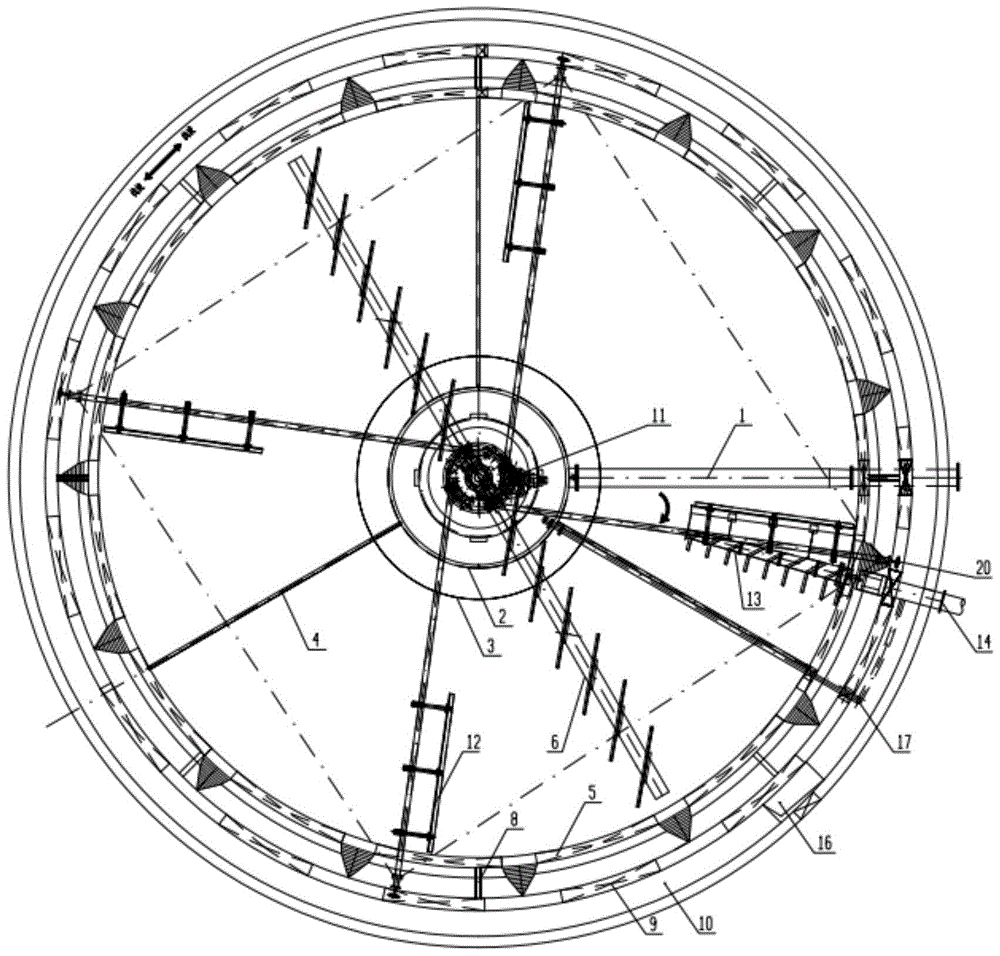

[0028] Use of the present invention will be further described below in conjunction with accompanying drawing:

[0029] Such as figure 1 In the upward flow circular oil separation pretreatment device shown, the water inlet pipe 1 enters from the upper water distribution cylinder 2, and most of the water is evenly dispersed from the top of the diffusion cone 3 to the surroundings under the action of the water distribution cylinder 2 and the diffusion cone 3, and some The suspended solids with higher density directly fall into the conical mud hopper through the bottom of the diffusion cone 3 . The water flowing out from the top of the diffusion cone 3 passes through the water hole 5 from top to bottom, enters the water well 8, and overflows to the water outlet channel 10 through the overflow weir plate installed on the overflow water hole 9 .

[0030] The oil scraper 19 of the surface skimmer 12 is attached to the scum separating plate 22 in front of the scum hopper 13, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com