Steel-aluminum composite hydraulic prop and manufacturing method and device thereof

A hydraulic prop, steel-aluminum composite technology, used in mining equipment, props/supports, earth-moving drilling, etc., can solve the difficulty in realizing the metallurgical combination of hydraulic prop core blank and stainless steel sleeve, and poor surface wear resistance and impact resistance. , difficulty in large-scale production, etc., to achieve the effects of controllable composition and thickness of the deposited layer, low overall density, and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

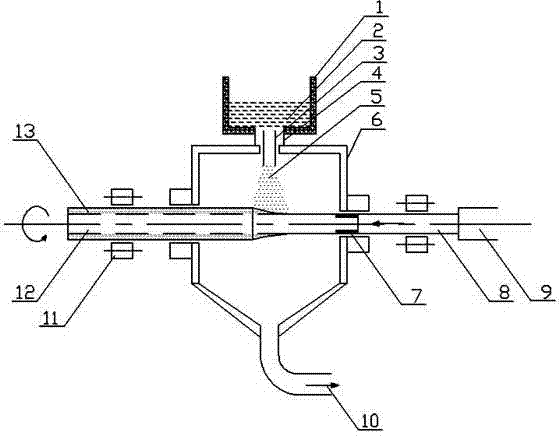

[0027] Example 1 Manufacturing equipment of steel-aluminum composite hydraulic prop

[0028] Such as figure 1 As shown, the manufacturing equipment of steel-aluminum composite hydraulic prop includes medium frequency induction furnace 1, catheter tube 3, atomizer 4, deposition chamber 6, fixture 7, ejector rod 8, ejector device 9, exhaust port 10, rotary Driving roller 11, aluminum alloy pillar core blank 12 and stainless steel deposition layer 13. The stainless steel material is melted in the intermediate frequency induction furnace 1 to form a stainless steel melt 2, and the stainless steel melt 2 is introduced into the atomizer 4 through the catheter 3, and the high-pressure nitrogen atomizes the stainless steel melt through the atomizer 4 to form a jet stream 5 .

[0029] Below the intermediate frequency induction furnace 1 is provided with a deposition chamber 6, and at the bottom of the intermediate frequency induction furnace 1 is provided with a liquid conduit 3 for ...

Embodiment 2

[0033] Example 2 Manufacture of Steel-Aluminum Composite Hydraulic Prop

[0034] The 7075 aluminum alloy prepared by extrusion casting was used as the pillar core billet, and the 304 stainless steel was used as the cladding material. The composite core billet experiment of the cladding layer was carried out by spray deposition. use figure 1 The steel-aluminum composite hydraulic prop manufacturing equipment shown is tested, and the experimental steps are as follows:

[0035] 1) Using a 100kW intermediate frequency induction melting furnace, first add 36kg of electrical pure iron block material to the furnace 1 of the magnesia furnace lining, turn on the intermediate frequency furnace, gradually increase the power to 85kW, and keep the frequency at about 2500Hz for melting. After the iron block is completely melted, add 4.5Kg Ni block, add 9Kg Cr block after melting, then add 1Kg Mo60%-Fe alloy to obtain 304 stainless steel melt 2, keep power about 90 kW, when the melt tempera...

Embodiment 3

[0040] Example 3 Manufacture of Steel-Aluminum Composite Hollow Pillars

[0041] Using 7075 aluminum alloy extruded 100×30 (outer diameter 100mm, wall thickness 30mm) tube billet as pillar core billet, 304 stainless steel as cladding material, spray deposition was used to carry out cladding layer composite core billet experiment. use figure 1 The steel-aluminum composite hydraulic prop manufacturing equipment shown is tested, and the experimental steps are as follows:

[0042] 1) Use a 100kW intermediate frequency induction melting furnace, add 50kg304 stainless steel rods, and the melting power is about 90kW. When the melt temperature is about 1550°C, add 50g of ferromanganese and 75g of ferrosilicon to conduct deoxidation and refining treatment on the stainless steel melt 2, and adjust the intermediate frequency The power of the furnace is about 100kW, so that the temperature of the stainless steel melt reaches 1600°C;

[0043] 2) Put the 100×30 (outer diameter 100mm, wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com