A liquid-liquid mixing device and method for processing polymer solution

A polymer solution and mixing device technology, applied in mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of complex process, poor residual catalyst effect, and high catalyst cost, and achieve simple process, easy continuous industrial production, Guaranteed micro-mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

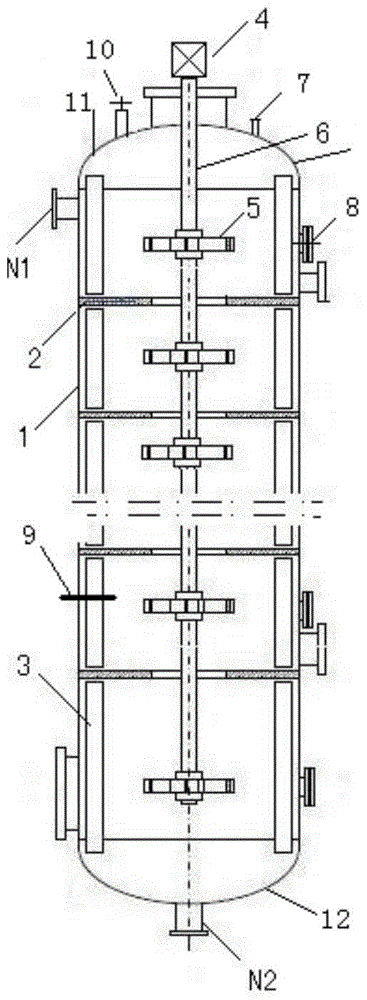

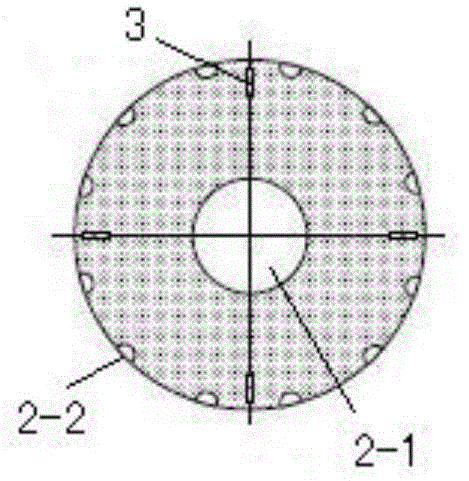

[0051] use Figure 1-3 The liquid-liquid mixing device shown includes: a cylinder body 1, a partition plate 2, a baffle plate 3, a stirring device 4, a stirring paddle 5, a stirring shaft 6, a venting balance pipe 7, a sight glass 8, a temperature measuring component 9, and a safety valve 10. The upper end head 11, the lower end head 12, the liquid inlet N1 and the liquid outlet N2. Wherein, the separation disc 2 has a central hole 2-1 and a flow guide hole 2-2.

[0052] The cylinder body 1 is divided into three mixing spaces in the axial direction by the partition plate 2 .

[0053] The disk surface of the separating disk 2 is horizontal, and the plate surface of the baffle plate 3 is vertical.

[0054] There is a gap between the baffle plate 3 and the inner wall of the cylinder body 1 . The ratio of the length of the gap along the radial direction of the cylinder 1 to the inner diameter of the cylinder 1 is 0.03:1.

[0055] In each mixing space, the ratio of the width of...

Embodiment 2

[0069] In a 5L polymerization kettle, a butadiene-styrene copolymer was synthesized with n-butyllithium as an initiator and a mixture of cyclohexane and n-hexane (the weight percent of cyclohexane was 87%) as a solvent. The copolymer concentration is 10.0% by weight based on the whole polymerization system, the number average molecular weight of the copolymer is 55,000, and the weight ratio of styrene to butadiene monomer units is 3:7. Triisobutylaluminum (Yanshan Synthetic Rubber Factory, industrial grade, concentration 3g / L) and nickel naphthenate (Yanshan Synthetic Rubber Factory, industrial grade, concentration 4g / L) are 4 according to the molar ratio (based on metal): 1 mix, add it to the butadiene-styrene block copolymer solution obtained above, and stir well. Finally, 1200 mL of a butadiene-styrene copolymer solution containing a hydrogenation catalyst was added into a 20 L autoclave for hydrogenation reaction. The hydrogenation reaction temperature is controlled at ab...

Embodiment 3

[0074] Adopt the device and method identical with embodiment 1, difference is:

[0075] There is no gap between the baffle plate 3 and the inner wall of the cylinder body 1 .

[0076] The residual metal content in the dry glue was determined by plasma emission spectrometry IPC, and the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com