Non-aqueous organic high-voltage electrolyte additive, non-aqueous organic high-voltage electrolyte and lithium ion secondary battery

An electrolyte additive, high-voltage technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of non-aqueous organic electrolyte hysteresis, inability to apply, battery safety performance threats, etc., to improve cycle performance and discharge capacity. , the effect of good cycle performance and discharge capacity, excellent electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

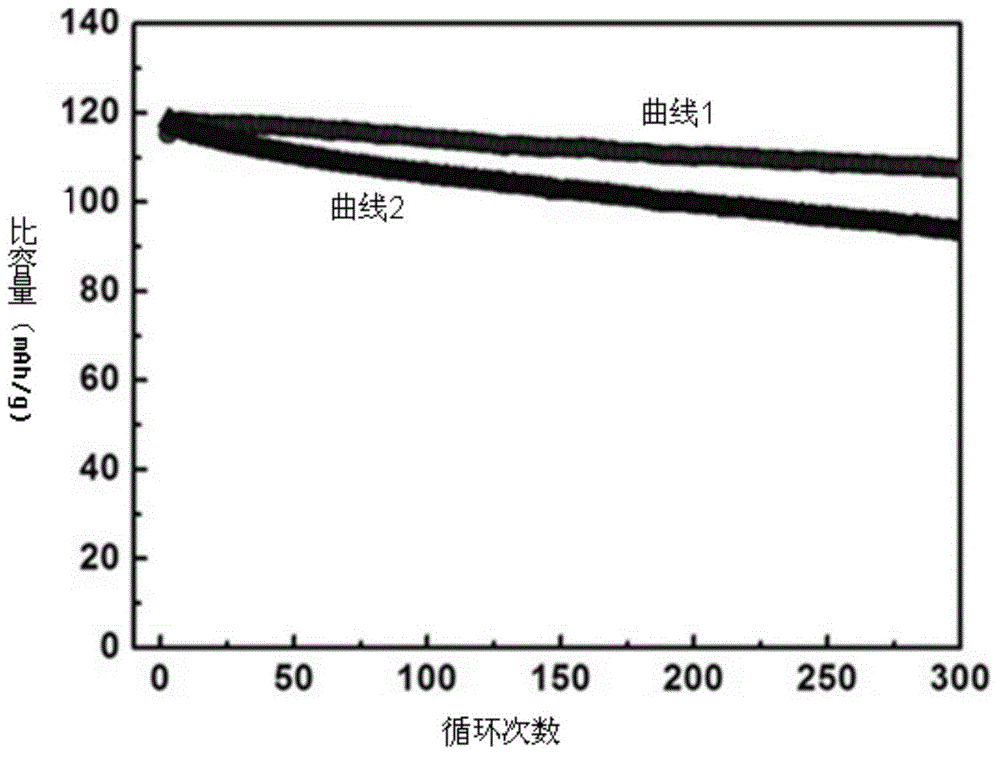

[0066] The preparation method of the lithium ion secondary battery is as follows: the positive electrode, the negative electrode and the diaphragm are made into a battery pole core, and the non-aqueous organic high-voltage electrolyte is injected to obtain the lithium ion secondary battery. The preparation method of the lithium ion secondary battery is simple and feasible.

[0067] The lithium ion secondary battery provided by the third aspect of the embodiment of the present invention has good cycle performance and discharge capacity.

Embodiment 1

[0070] Preparation of nonaqueous organic high voltage electrolyte:

[0071] Mix ethylene carbonate (EC) and dimethyl carbonate (DMC) according to the mass ratio EC:DMC=1:2, and use molecular sieves, calcium hydride, and lithium hydride to purify and remove impurities and water to obtain a non-aqueous organic solvent; At room temperature, the conductive lithium salt LiPF 6 Dissolve in the non-aqueous organic solvent obtained above, the final concentration of the lithium salt is 1.0mol / L, stir evenly to obtain a lithium salt solution, add the non-aqueous organic high-voltage electrolyte additive p-trifluoromethylbenzene to the obtained lithium salt solution formonitrile, stirring, obtained non-aqueous organic electrolyte A, in terms of mass fraction, the non-aqueous organic high-voltage electrolyte additive p-trifluoromethylbenzonitrile accounts for 1% of the non-aqueous organic high-voltage electrolyte.

[0072] The manufacturing method of the lithium-ion secondary battery acc...

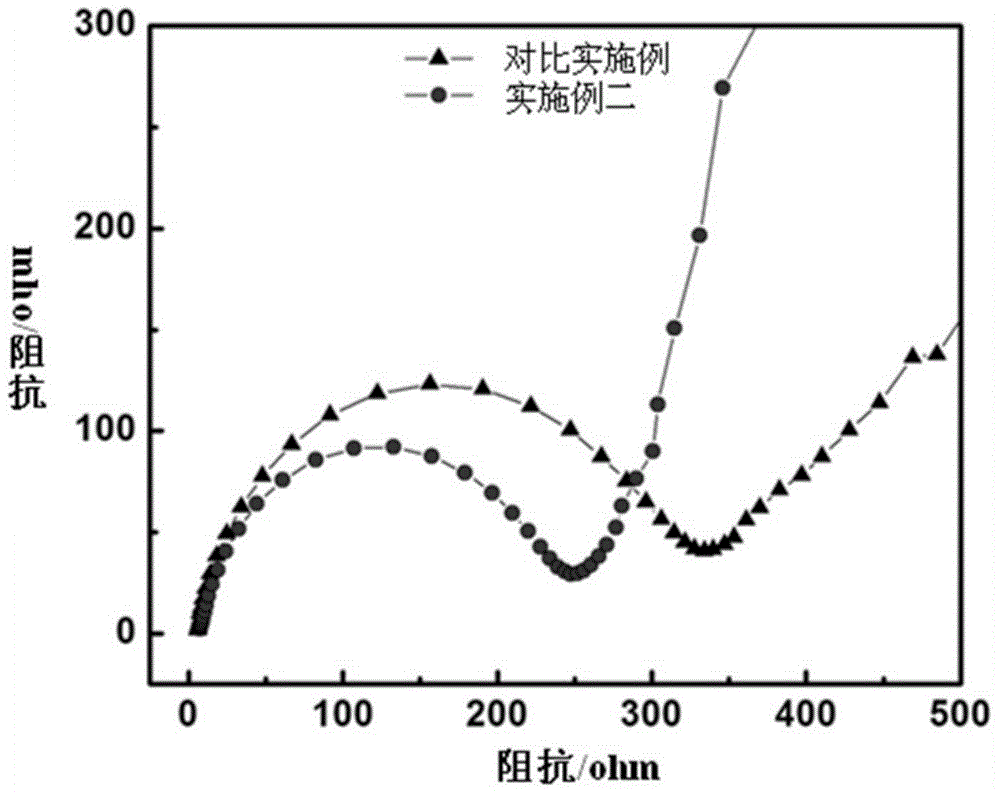

Embodiment 2

[0082] Non-aqueous organic electrolytic solution B was prepared in the same manner as in Example 1, the only difference being that, in terms of mass fraction, the non-aqueous organic high-voltage electrolytic solution additive accounted for the proportion of trifluoromethyl benzonitrile in the non-aqueous organic high-voltage electrolytic solution 0.5% of B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com