Low-thermal-noise high-reflection type optical combined film structure and preparation method thereof

A reflective optics and high-noise technology, applied in the field of composite films, can solve problems such as large frequency stability, increased spot radius, and large mechanical loss factor, and achieve low mechanical loss factor, reduced Brownian thermal noise, and high reflectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

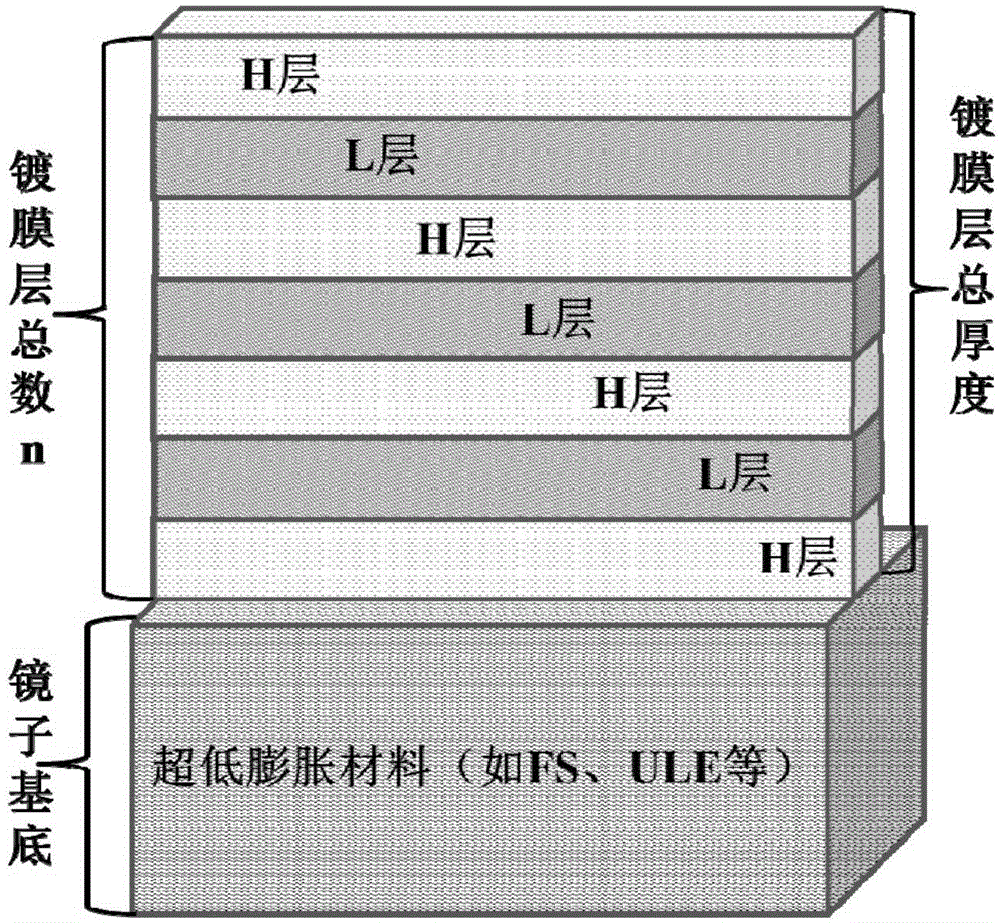

[0026] The present invention also proposes a method for preparing the above-mentioned low-thermal-noise and high-reflection optical composite film structure, comprising the following steps:

[0027] 1) Select the base

[0028] The ultra-low expansion optical material is made into the lens base, and it is polished to ensure the surface finish;

[0029] 2) Select molecular beam epitaxy or magnetron sputtering method for coating;

[0030] 3) Determination of film size and quantity

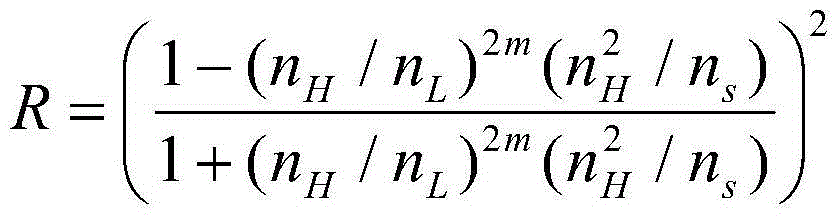

[0031] The thickness of the diamond film layer, namely the H layer, is T H , the thickness of the diamond film layer, namely the L layer, is T L , the number of layers of the L layer is m, then the number of layers of the H layer is m+1, and the number of layers of the total film layer is n=2m+1; the number of layers of the film layer is determined according to the following formula:

[0032] R = ( 1 ...

Embodiment 1

[0038] 1. Select the substrate: make FS (fused silica) into a lens substrate of a certain size (including thickness, diameter, etc.) that meets the requirements, and polish it to ensure its surface finish and the quality of the coating;

[0039] 2. The present invention selects two kinds of film layers (sapphire film layer and diamond film layer) to be plated alternately: in order to obtain a lower mechanical loss factor, both the sapphire film layer and the diamond film layer must have very high hardness. Sapphire and diamond materials already have high hardness and low mechanical loss factor. How to adopt a better coating method to ensure the hardness of the coated film layer is one of the key points of the present invention. In order to meet the above requirements, this embodiment chooses the molecular beam epitaxy growth method for coating;

[0040] 3. Determination of the size and quantity of the film layer: Under the conditions determined by the coating technology, accor...

Embodiment 2

[0045] 1. Select the substrate: ULE (ultra-low expansion glass) is made into a lens substrate of the required size (including thickness and diameter), and it is polished to ensure its surface finish and the quality of the coating;

[0046] 2. The present invention selects two kinds of film layers (sapphire film layer and diamond film layer) to be plated alternately: in order to obtain a lower mechanical loss factor, both the sapphire film layer and the diamond film layer must have very high hardness. Sapphire and diamond materials already have high hardness and low mechanical loss factor. How to adopt a better coating method to ensure the hardness of the coated film layer is one of the key points of the present invention. In order to meet the above requirements, methods such as magnetron sputtering are selected for coating in this embodiment;

[0047] 3. Determination of the size and quantity of the film layer: Under the conditions determined by the coating technology, accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com