Simple hydraulic support for similar material simulation tests

A simulation test, hydraulic support technology, applied in pillars/supports, mining equipment, earthwork drilling, etc., can solve the problems of spring prone to elastic fatigue, complicated system process, and easily limited support size, etc., to achieve simple manufacturing process, Solve the effect of complex production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention provides a simple hydraulic support for similar material simulation tests. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail in conjunction with the accompanying drawings and specific examples below.

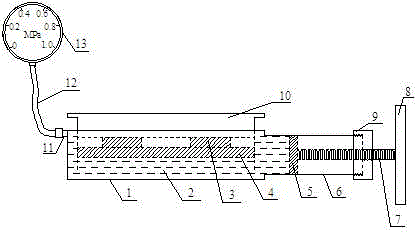

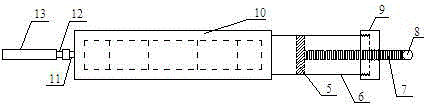

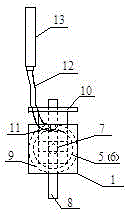

[0017] Such as figure 1 , figure 2 and image 3 As shown, a simple hydraulic support for similar material simulation tests, including oil cylinders 1, 6, propulsion body, support body 10 and hydraulic gauge 13; the main body of the oil cylinder 1 is a cuboid with a lifting piston 4 inside, and the lifting piston 4 and 2 The two connecting columns 3 and the support body 10 are welded together and move up and down with the hydraulic oil 2. The auxiliary body 6 of the oil cylinder is a cylinder with a propelling piston 5 inside. The propulsion body is welded by the propulsion column 7, the propulsion piston 5 and the rotary handle 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com