Construction method of novel vertical shaft horizontal rotation jet grouting pile foundation pit sealing bottom water-resisting layer

A technology of horizontal jet grouting piles and bottom sealing of foundation pits, which is applied in foundation structure engineering, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

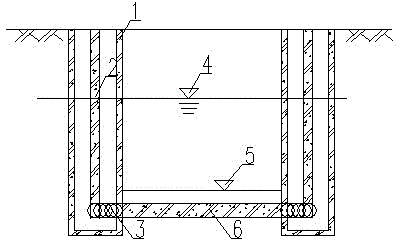

[0031] The groundwater table 4 is located above the horizontal water-resisting layer 6 at the bottom of the foundation pit.

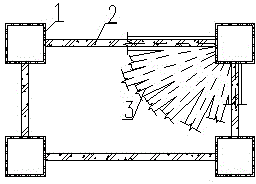

[0032] Such as figure 1 , figure 2 As shown, the shaft 1 is set around the foundation pit. The size of the shaft 1 is a square with a side length of 4600 mm, which meets the minimum size requirements for the construction of horizontal jet grouting piles. The depth of the shaft should reach 1500 mm below the bottom elevation of the foundation pit. Radial construction of horizontal jet grouting piles 3 within the range, the radial horizontal jet grouting piles complete the full coverage of the bottom of the foundation pit, forming an artificial horizontal water-resistant layer 6 at the bottom of the foundation pit. The horizontal water-resistant layer at the bottom of the foundation pit and After the water-stop curtain 2 on the side wall of the foundation pit forms a closed water-proof system, the pit is dewatered, and the excavation of the foundation ...

Embodiment 2

[0044] The size of shaft 1 is a square with a side length of 5000 mm, which meets the minimum size requirements for the construction of horizontal jet grouting piles.

[0045] The depth of the shaft should reach 1000mm below the elevation of the bottom surface of the foundation pit. All the other technical features are the same as in Embodiment 1.

Embodiment 3

[0047]The size of shaft 1 is a square with a side length of 4000 mm, which meets the minimum size requirements for the construction of horizontal jet grouting piles. The depth of the shaft should reach 1200mm below the elevation of the bottom surface of the foundation pit. All the other technical features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com