Preparation method of high-strength polyacrylonitrile nano-composite fiber

A nanocomposite fiber and polyacrylonitrile technology, which is applied in fiber treatment, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of low molecular orientation of PAN, low tensile strength and modulus of carbon fiber, and thermal stretching ratio. minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

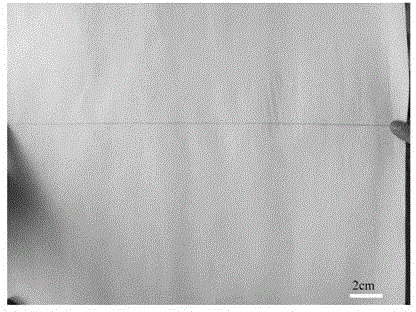

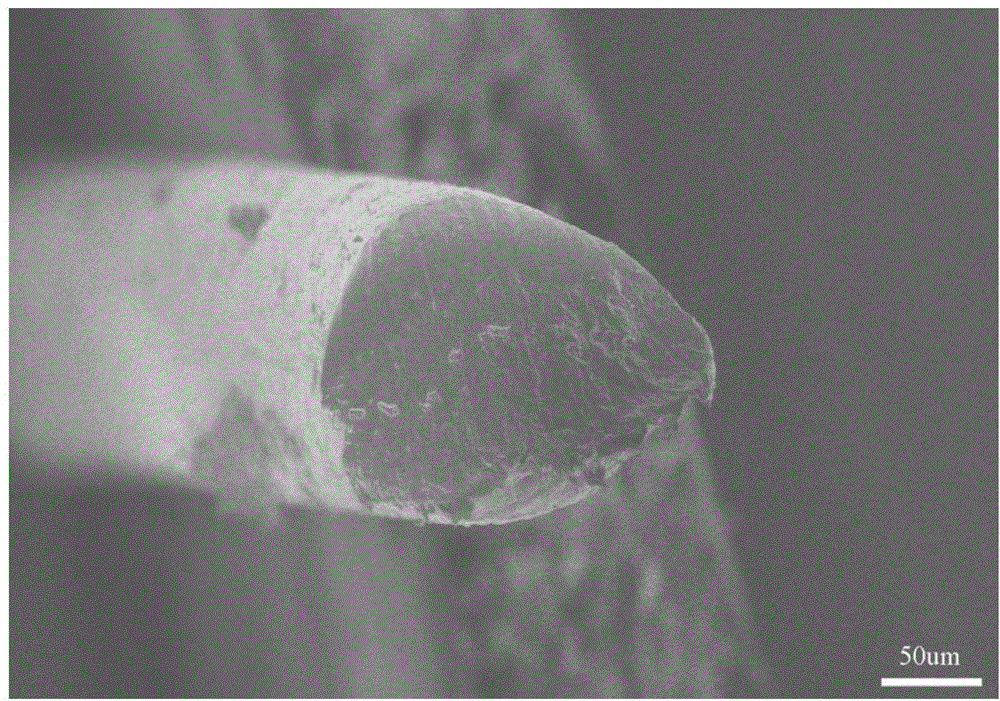

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for preparing high-strength polyacrylonitrile nanocomposite fibers, the preparation method comprising the following steps:

[0034] Graphene oxide was added to a mixed solvent containing dimethyl sulfoxide (DMSO): water = 95: 5, and ultrasonically dispersed for 1 h. Add polyacrylonitrile with a molecular weight of 88,000 to the mixed solvent, stir and dissolve at 50°C for 2 hours. The weight percentage of graphene oxide is 0.3%, and the weight percentage of polyacrylonitrile is 30%;

[0035] Degassing at normal pressure for 8 hours, the degassing temperature is 30°C, and the temperature of the spinning stock solution is 30°C. After filtering, it enters the 60 / 40 (V / V) DMSO / water at -10°C through a spinneret with an aperture of 0.10mm. In the coagulation bath, the primary fibers in jelly state are formed;

[0036]The jelly fibers were stretched and extracted in a methanol bath at -20°C to remove dimethyl sulfoxide; the extraction time ...

Embodiment 2

[0039] This embodiment provides a method for preparing high-strength polyacrylonitrile nanocomposite fibers, the preparation method comprising the following steps:

[0040] The electrochemically exfoliated graphene was added to a mixed solvent containing dimethylformamide: water = 70: 30, and ultrasonically dispersed for 2 hours. Add polyacrylonitrile with a molecular weight of 50,000 to the mixed solvent, stir and dissolve at 80° C. for 2 hours; the weight percentage of graphene oxide is 0.05%, and the weight percentage of polyacrylonitrile is 15%;

[0041] Degassing at normal pressure for 6 hours, the degassing temperature is 50°C, and the temperature of the spinning stock solution is 50°C. After filtration, the spinneret with an aperture of 0.25mm enters the 60 / 40 (V / V) dimethyl In the coagulation bath of formamide / water, the as-spun fibers of jelly state are formed;

[0042] The jelly fiber was stretched and extracted in a methanol bath at 60°C to remove dimethyl sulfoxid...

Embodiment 3

[0045] This embodiment provides a method for preparing high-strength polyacrylonitrile nanocomposite fibers, the preparation method comprising the following steps:

[0046] Amino-modified graphene oxide was added to the solution of sodium thiocyanate, ultrasonically dispersed for 4 hours; polyacrylonitrile with a molecular weight of 120,000 was added to the mixed solvent, and stirred and dissolved at 80°C for 2 hours; the modified graphene The weight percentage is 10%, and the weight percentage of polyacrylonitrile is 25%;

[0047] Degassing under normal pressure for 8 hours, the degassing temperature is 80°C, and the temperature of the spinning stock solution is 80°C; after filtering, it enters the 60 / 40 (V / V) distilled water coagulation bath at -5°C through a spinneret with an aperture of 0.06mm In the process, the primary fibers in jelly state are formed;

[0048] The jelly fibers were stretched and extracted in a methanol bath at 30°C to remove the solvent; the extraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com