A kind of explosion-proof and anti-explosion floor material and preparation method thereof

A floor material and ferroalloy technology, applied in the field of floor materials, can solve the problems of low fire protection, high cost, and environmental pollution, achieve strong antifreeze and heat resistance, enhance impact resistance, and improve the indoor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

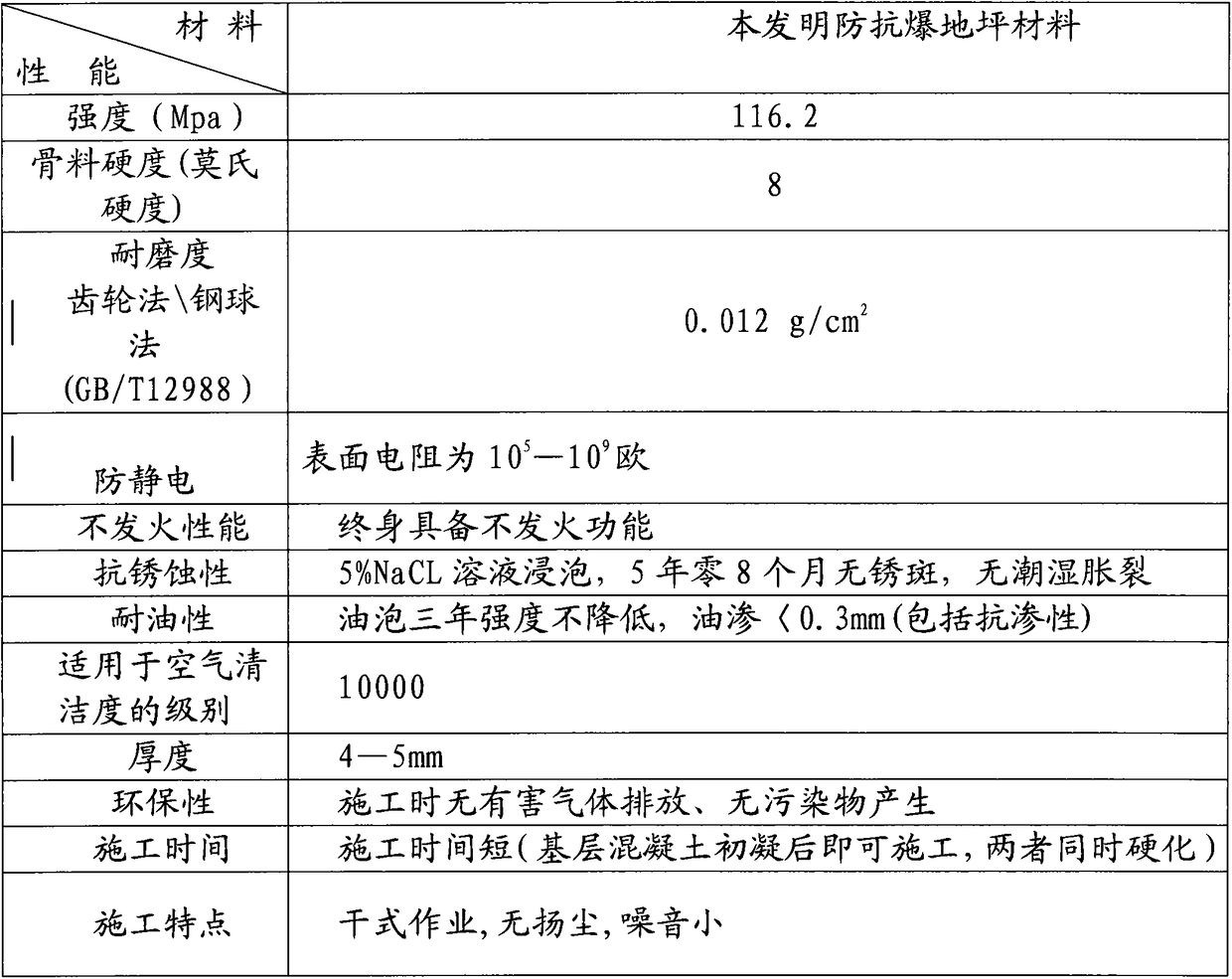

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of material of the present invention

[0026] 1) Preparation of ferroalloy particles: the mass percentage of chemical composition is: iron 85%, manganese 8%, silicon 6%, and the balance is carbon ferroalloy pulverized to particles below -100 mesh, then magnetically separated by magnetic separator to remove impurities, Then screen with a vibrating sieve to obtain ferroalloy particles of about -100 mesh;

[0027] 2) Foaming: Put the ferroalloy pellets in step 1) into a sintering tank and send it to a high-temperature furnace to raise the temperature to 1500°C, add silicon carbonate and rare earth to roast and foam for 30 hours, and the roasted and foamed material is quickly cooled to room temperature , and then crushed to about 100 mesh by a pulverizer to make it a porous particle;

[0028] 3) Modification: Send the granules obtained in step 2) into a roasting furnace to raise the temperature to 1000°C, add rare earth and mix them, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com