Method for preparing high-purity metal cesium by using molecular distillation apparatus

A molecular distillation, metal cesium technology, applied in the direction of improving process efficiency, can solve problems such as unsatisfactory impurity removal effect, low utilization rate of raw materials, low distillation efficiency, etc., to achieve protection from pollution and damage, and good impurity removal effect. , the effect of short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below:

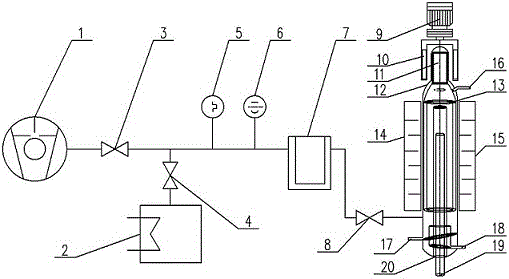

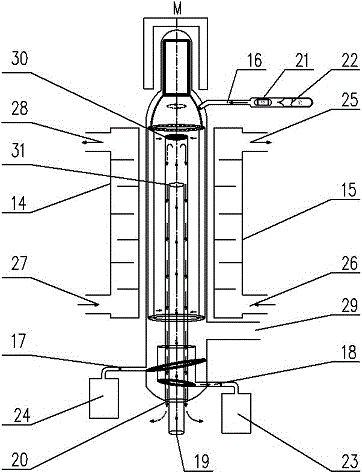

[0024] as attached figure 1 As shown, an ultra-high vacuum molecular distillation equipment includes an ultra-high vacuum system and a molecular still. The ultra-high vacuum system is composed of a pumping unit and a vacuum measuring unit. The pumping unit is composed of a dry pump 1 as a backing pump Connected with the cryopump 2, the vacuum measurement unit is composed of a resistance vacuum gauge 5 and an ionization vacuum gauge 6 arranged on the vacuum pipeline between the cryopump 2 and the liquid nitrogen cold trap 7, and the liquid nitrogen cold trap 7 is connected with the molecular still A regulating ball valve 8 is arranged between them; the molecular still has a glass shell structure as a whole, and the still is composed of an outer shell 12, a feed port 16 connected to the upper side of the outer shell 12, and a heavy fraction connected to both sides of the lower end of the outer shell 12. Outlet 17 and li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com