Hybrid heating equipment and application thereof

A heating equipment and hybrid technology, applied in the field of hybrid heating equipment, can solve the problems of large heat loss, easy coking and clogging at the feed end, and can only be used as fuel, etc., to accelerate heat exchange efficiency, improve safe operation rate, avoid The effect of coking blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

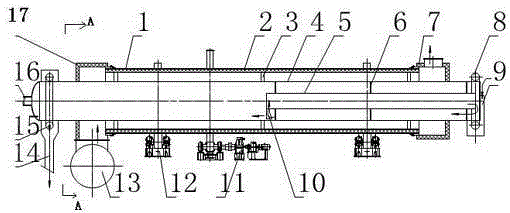

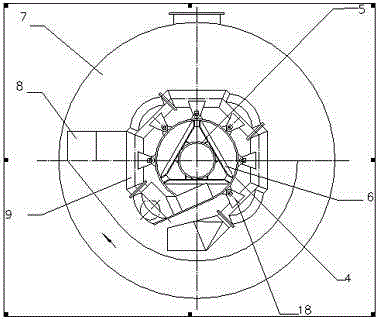

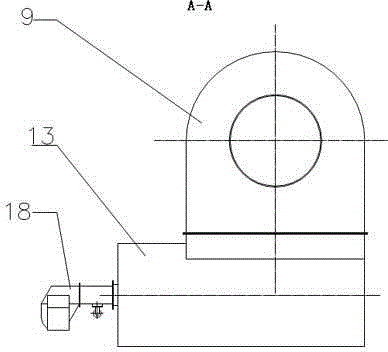

[0052] Such as figure 1 As shown, a hybrid heating device includes a three-layer cylinder structure composed of an outer cylinder 1, a heating cylinder 4, and a slag returning cylinder 5 from outside to inside, wherein the two ends of the heating cylinder 4 extend axially to Outside the outer cylinder 1, the axial length of the outer cylinder 1 is greater than the axial length of the slag returning cylinder 5; one end of the slag returning cylinder 5 is flush with the end of the heating cylinder 4 for feeding; the The inner wall of the outer cylinder 1 is provided with an insulating material layer 2;

[0053] The outer cylinder 1 is supported by a supporting device 12 and driven to rotate by a transmission device 11;

[0054] A first support member 3 is provided between the inner wall of the outer cylinder 1 and the outer wall of the heating cylinder 4, and a second support member 6 is provided between the inner wall of the heating cylinder 4 and the outer wall of the slag re...

Embodiment 2

[0067] This example is basically the same as Example 1, except that the raw material is heated in the heating cylinder at 650°C for 1 hour. After using this equipment to heat the semi-coke, compared with heating the semi-coke with an internal heating type vertical furnace, the calorific value of the obtained gas is improved. The content of hydrogen and methane has also increased by 60%, and the content of nitrogen has decreased by 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com