Process method for effectively adjusting the carbon chain length of mixed alcohol products from syngas

A process method and technology of carbon chain length, which is applied in the field of effectively adjusting the carbon chain length of mixed alcohol products from syngas, can solve problems such as poor stability, harsh catalytic process, poisoning, etc., achieve strong flexibility, easy industrialization, and reduce operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

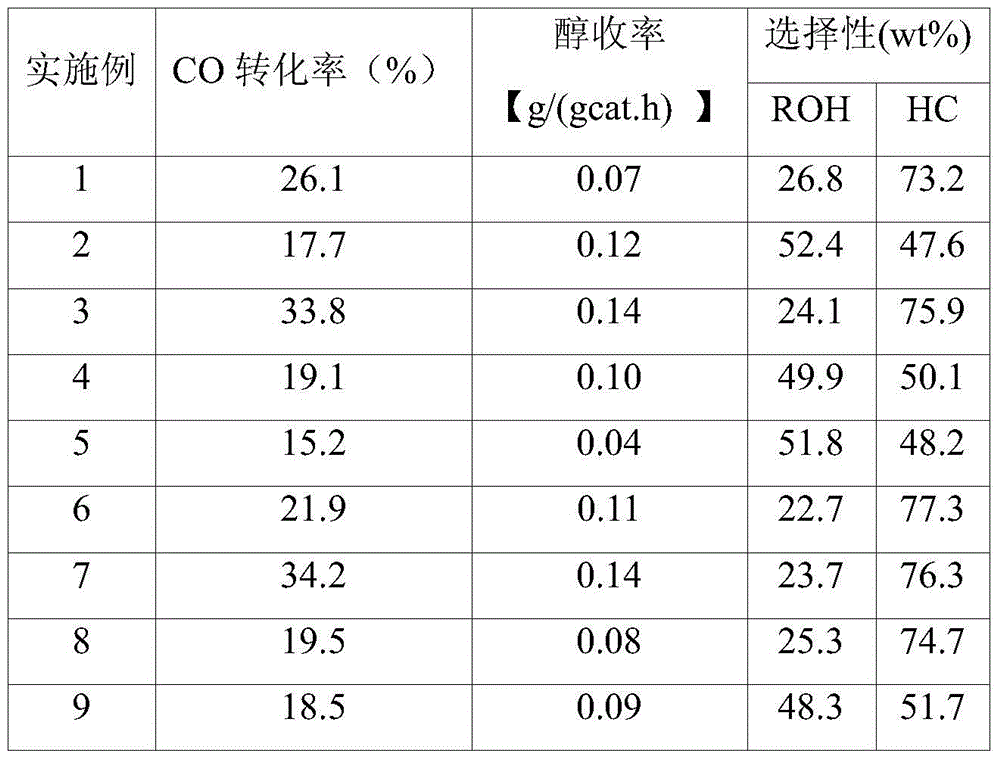

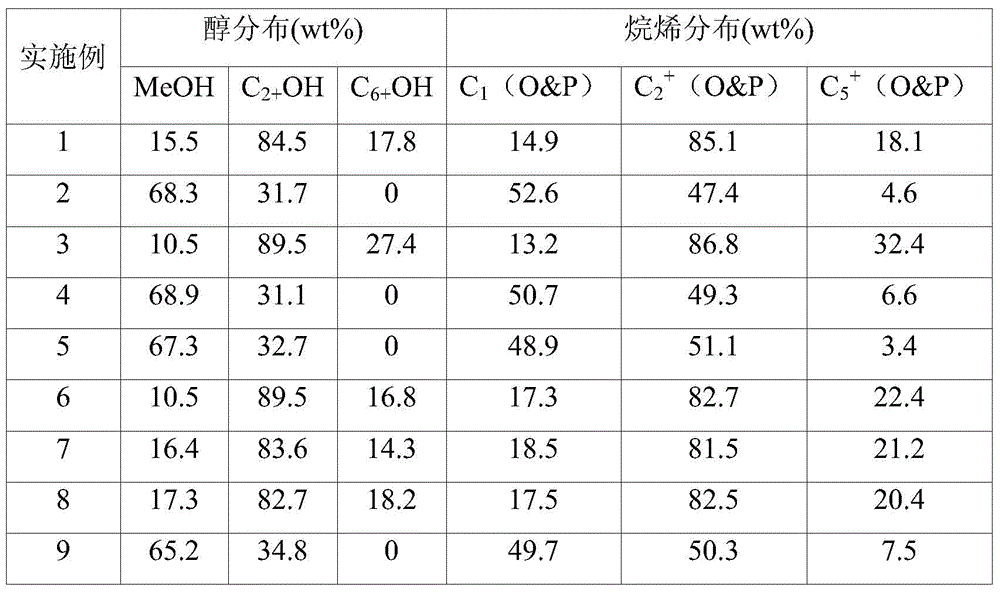

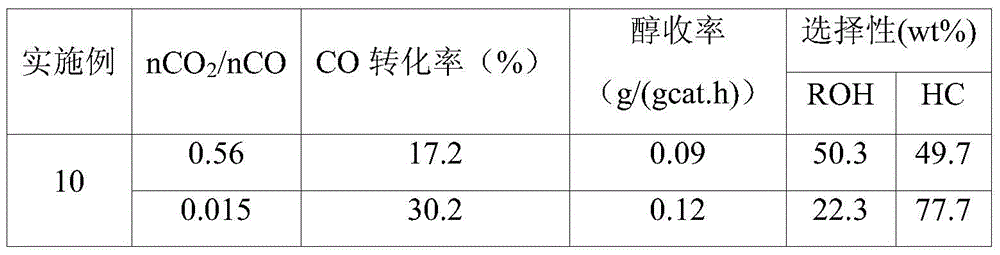

Examples

Embodiment 1

[0032] The catalyst used for the synthesis reaction of mixed alcohols in this example (i.e., the catalyst for synthesizing alcohols) is prepared according to Chinese patent application CN101327435A, and the weight percentages of each metal in the obtained catalyst are as follows:

[0033] Cu: 33.77%, Fe: 43.21%, Mn: 14.20%, Zn: 6.76%, K: 2.06%.

[0034] The reaction device in this example is a fixed bed reactor.

[0035] The catalyst is pressed into tablets and crushed to 40-60 mesh, and loaded into a reaction tube. The filling volume is 1.5ml, diluted with 1.5ml fine quartz sand, and the reducing atmosphere is H 2 , the reduction airspeed is 15000h -1 , the reduction was performed after heating up to 250°C at a rate of 1.2°C / min, and the reduction time was 6h. After the restore process ends, start with N 2 The reactor pressure was back pressured to 6.0MPa, then lowered to 180°C, and the N in the reactor was gradually replaced by syngas 2 , After about 24h, after venting,...

Embodiment 2

[0037] The catalyst for synthesizing alcohol in this example is prepared according to Chinese patent application CN101327435A, and the weight percentage of each metal in the catalyst is Cu: 33.77%, Fe: 43.21%, Mn: 14.20%, Zn: 6.76%, K: 2.06%.

[0038] The reaction device in this example is a fixed bed reactor.

[0039] The catalyst is pressed into tablets and crushed to 40-60 mesh, filled in a reaction tube with a loading volume of 1.5ml, diluted with 2.25ml of fine quartz sand, and the reducing atmosphere is synthetic gas (H 2 , CO, CO 2 mixture), the reduction space velocity is 16000h -1 , the reduction was performed after heating up to 250°C at a rate of 1.5°C / min, and the reduction time was 6h. After the restore process ends, start with N 2 The reactor pressure was back pressured to 6.0MPa, then lowered to 180°C, and the N in the reactor was gradually replaced by syngas 2 , After about 24h, after venting, the reaction began. The reaction conditions are: H in the synth...

Embodiment 3

[0041] The catalyst for synthesizing alcohol in this example is prepared according to Chinese patent application CN101327435A, and the weight percentage of each metal in the catalyst is Cu: 33.77%, Fe: 43.21%, Mn: 14.20%, Zn: 6.76%, K: 2.06%. The reaction device in this example is a fixed bed reactor.

[0042] The catalyst is pressed into tablets and crushed to 40-60 mesh, filled in a reaction tube with a loading volume of 1.5ml, diluted with 1.8ml of fine quartz sand, and the reducing atmosphere is synthetic gas (H 2 , CO, CO 2 mixture), the reduction space velocity is 17000h -1 , the reduction was performed after heating up to 300°C at a rate of 1.6°C / min, and the reduction time was 6h. After the restore process ends, start with N 2 The reactor pressure was back pressured to 6.0MPa, then lowered to 160°C, and the N in the reactor was gradually replaced by syngas 2 , After about 24h, after venting, the reaction began. The reaction conditions are: H in the synthesis gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com