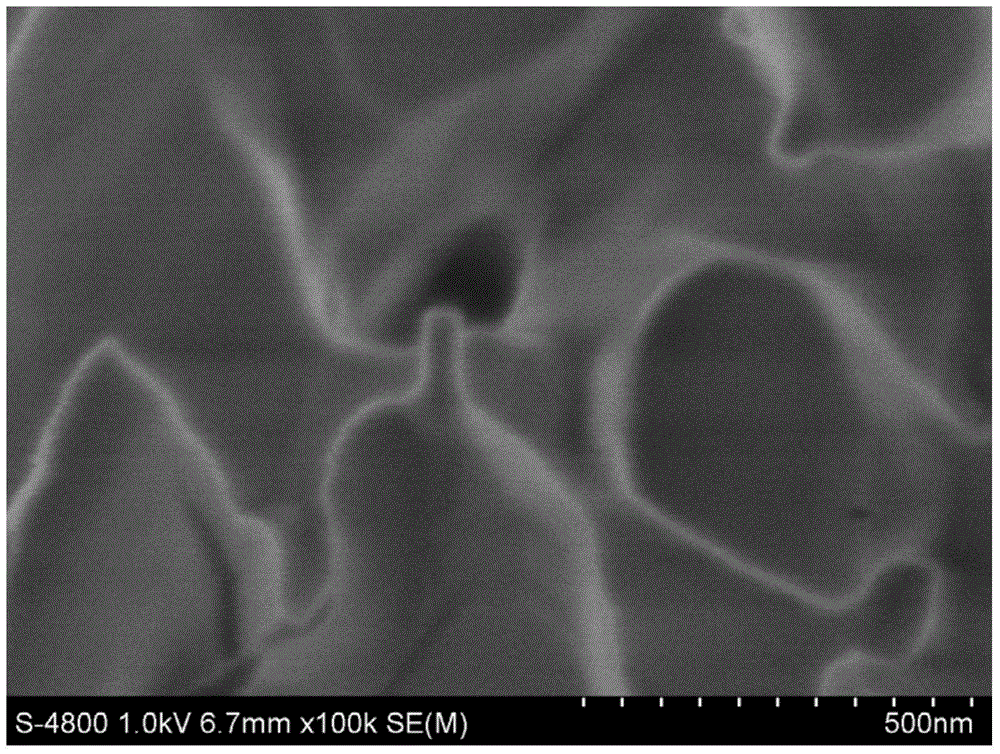

Double in-situ synthesis method for preparing carbon nano tube reinforced hydroxyapatite composite materials

A nano-hydroxyapatite, hydroxyapatite technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry and other directions, can solve the problem of small interface binding force, difficult to achieve carbon nanotube dispersion effect and interface binding effect, hydroxyl Apatite composite materials are difficult to clinically apply and other problems to avoid toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first step, in-situ synthesis of carbon nanotube-hydroxyapatite in-situ mixed powder:

[0030] Be nanometer ferric oxide by mass ratio: the ratio of nanometer hydroxyapatite=0.026: 1, take by weighing required nanometer ferric oxide and nanometer hydroxyapatite, adopt agate mortar to mix the two homogeneously, will The quartz ark containing the above mixture was placed in the constant temperature zone of the horizontal tube furnace, and nitrogen gas was introduced into the tube furnace at a flow rate of 90mL / min and the temperature was raised to 600°C. Pass hydrogen into the formula furnace and keep it warm for 0.5h to obtain the iron-hydroxyapatite catalyst. Then turn off the hydrogen and continue to let the mixed gas with a volume ratio of nitrogen:propane=20:1 at a flow rate of 300mL / min and keep warm for 0.5 h, then turn off the propane and adjust the nitrogen flow, so that the quartz ark equipped with the above mixture in the tube furnace is cooled to room temp...

Embodiment 2

[0040] The first step, in-situ synthesis of carbon nanotube-hydroxyapatite in-situ mixed powder:

[0041] Be nanometer ferric oxide by mass ratio: the ratio of nanometer hydroxyapatite=0.1: 1, take by weighing required nanometer ferric oxide and nanometer hydroxyapatite, adopt agate mortar to mix the two homogeneously, will The quartz ark containing the above mixture was placed in the constant temperature zone of the horizontal tube furnace, and nitrogen gas was introduced into the tube furnace at a flow rate of 110mL / min and the temperature was raised to 700°C. Pass hydrogen into the formula furnace and keep it warm for 1.5h to obtain the iron-hydroxyapatite catalyst. Then turn off the hydrogen, and continue to pass the mixed gas with a volume ratio of nitrogen:propane=30:1 at a flow rate of 400mL / min, and keep warm for 0.75 h, then turn off the propane and adjust the nitrogen flow, so that the quartz ark equipped with the above mixture in the tube furnace is cooled to room t...

Embodiment 3

[0047] The first step, in-situ synthesis of carbon nanotube-hydroxyapatite in-situ mixed powder:

[0048] Be nanometer ferric oxide by mass ratio: the ratio of nanometer hydroxyapatite=0.176: 1, take by weighing required nanometer ferric oxide and nanometer hydroxyapatite, adopt agate mortar to mix the two homogeneously, will The quartz ark containing the above mixture was placed in the constant temperature zone of the horizontal tube furnace, and nitrogen gas was introduced into the tube furnace at a flow rate of 130mL / min and the temperature was raised to 800°C, then the nitrogen gas was turned off, and the tube furnace was injected at a flow rate of 130mL / min. Pass hydrogen into the formula furnace and keep it warm for 2.5h to obtain the iron-hydroxyapatite catalyst, then turn off the hydrogen, and continue to let the mixed gas with a volume ratio of nitrogen:propane=40:1 at a flow rate of 500mL / min and keep it warm for 1h , then turn off the propane and adjust the nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com