Preparation method of mesoporous graphite-phase carbon nitride material

A graphite phase carbon nitride and mesoporous technology, applied in the direction of nitrogen and non-metallic compounds, can solve the problems of large sheet thickness and small specific surface area, and achieve the effect of improving activity, large specific surface area, and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Such as Figure 5 Shown, a kind of preparation method of mesoporous graphite phase carbon nitride material comprises the following steps:

[0031] (1) Weigh 10 g of nano colloidal SiO 2 Put into 5 g concentration and be in the cyanamide aqueous solution of 50 wt%, stir 4 h at room temperature and make it fully mix;

[0032] (2) Let the mixed solution in step (1) stand, remove the supernatant and dry it in an oven at 60°C to obtain a white solid;

[0033] (3) Grind the white solid obtained in step (2), place it in a muffle furnace for calcination at 500 °C for 6 h, and then grind it to obtain a light yellow powder;

[0034] (4) Disperse the light yellow powder obtained in step (3) in 400 mL of NH with a concentration of 2 mol / L 4 HF 2 Stir in the solution for 64 h, wash with deionized water and ethanol once, and dry at 70 °C for 1 h to obtain mpg-C 3 N 4 Material.

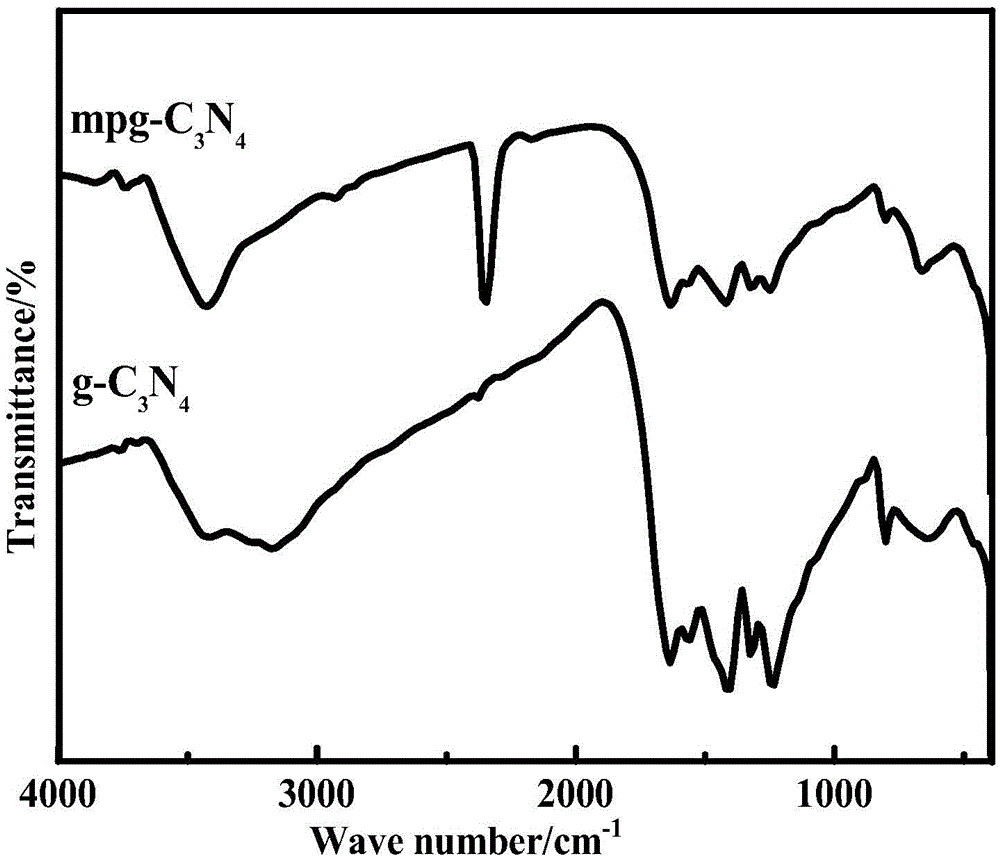

[0035] The mpg-C prepared by embodiment 1 3 N 4 Material, observed by Fourier transform infrared ...

Embodiment 2

[0037] Such as Figure 5 Shown, a kind of preparation method of mesoporous graphite phase carbon nitride material comprises the following steps:

[0038] (1) Weigh 30 g of nano colloidal SiO 2 Put into 10 g concentration and be in the cyanamide aqueous solution of 50 wt%, stir 2 h at room temperature and make it fully mix;

[0039] (2) Let the mixed solution in step (1) stand, remove the supernatant and dry in an oven at 50°C to obtain a white solid;

[0040] (3) Grind the white solid obtained in step (2), place it in a muffle furnace for calcination at 550 °C for 4 h, and then grind it to obtain a light yellow powder;

[0041] (4) Disperse the light yellow powder obtained in step (3) in 200 mL of NH with a concentration of 4 mol / L 4 HF 2 Stir in the solution for 48 h, wash twice with deionized water and ethanol, and dry at 50 °C for 2 h to obtain mpg-C 3 N 4 Material.

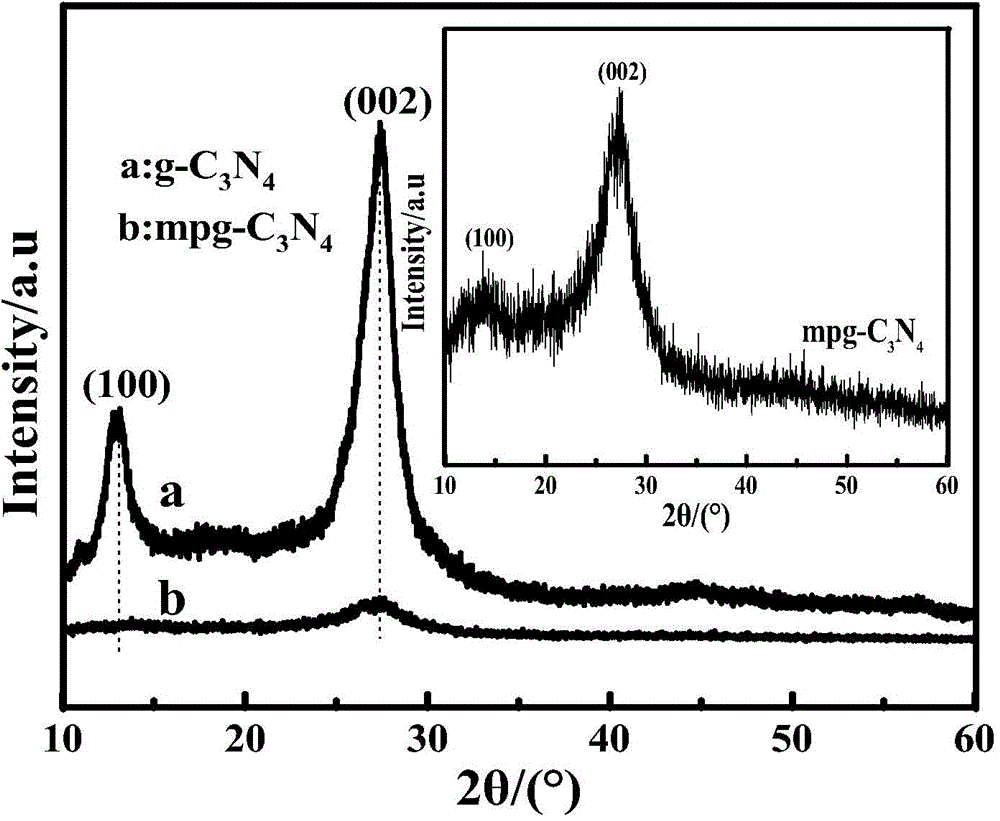

[0042] With the material prepared by the method of embodiment 2, after X-ray diffractometer scannin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com