Preparation method for nanorod-cluster-shaped Pt

A nanorod and cluster technology, which is applied in the field of preparation of nanorod cluster Pt, can solve the problem of high cost of platinum catalyst and achieve the effects of high electrochemical stability, large specific surface area and simplified preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of nanorod cluster Pt, comprising the steps of:

[0030] Put 3.53g of octadecylamine in a glass screw-top reagent bottle, heat and melt at 60°C to a colorless and clear solution;

[0031] 8 mg of platinum acetylacetonate was added to the colorless clear solution, and the solution was ultrasonicated above 60°C to a light yellow-green clear solution;

[0032] The above clarified mixed solution was placed in an oil bath at 170°C for 10 h. After the reaction is complete, the cooled reaction system is solid and melted after heating at about 60°C. Add an appropriate amount of a mixed solution of ethanol and cyclohexane with a volume ratio of 8:1, shake and wash thoroughly, and centrifuge at more than 8000 per minute. For more than 10 minutes, wash for more than five times and then wash with absolute ethanol for more than three times. The washed product was dispersed in 1ml of absolute ethanol for subsequent testing.

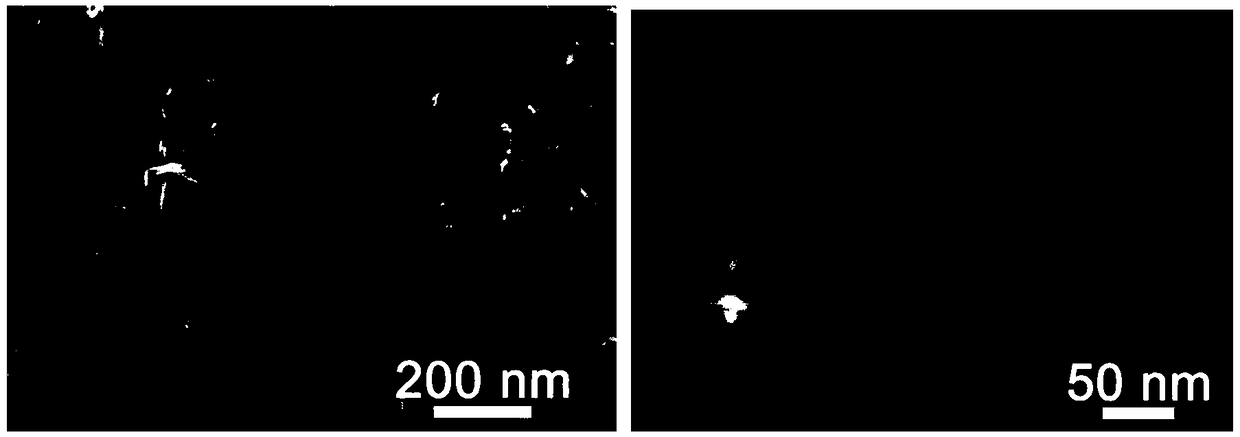

[0033] The SEM image of nanorod cl...

Embodiment 2

[0041] A preparation method of nanorod cluster metal Pt, comprising the steps of:

[0042] Put 3.45g of hexadecylamine in a glass screw-top reagent bottle, and heat and melt at 55°C to a colorless and clear solution;

[0043] 8 mg of platinum acetylacetonate was added to the colorless clear solution, and the solution was ultrasonicated above 60°C to a light yellow-green clear solution;

[0044] The above clarified mixed solution was placed in an oil bath at 170°C for 10 h.

[0045] The preparation method described in this example can effectively prepare nanorod cluster Pt, from Figure 6 The SEM image of the nanorod cluster Pt can be observed as a radial structure, and its overall size is 200nm to 250nm. Each nanorod cluster Pt is composed of about 20 to 50 nanorods, and each nanorod is about 75nm to 125nm long. The diameter is about 5nm to 10nm, and the nanorod cluster structure is uniform, the dispersion degree is small, and the orientation of the nanorods on each nanorod ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrochemically active area | aaaaa | aaaaa |

| Electrochemically active area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com