Magnetic-concentration medium, magnetic-concentration medium box, magnetic-concentration medium column and application thereof for magnetic separator

A technology of magnetic gathering medium and magnetic separator, which is applied in the field of mineral processing, can solve the problems of difficult processing and manufacturing, high cost, complex shape, etc., and achieve the effect of improving mineral recovery rate, facilitating recovery and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

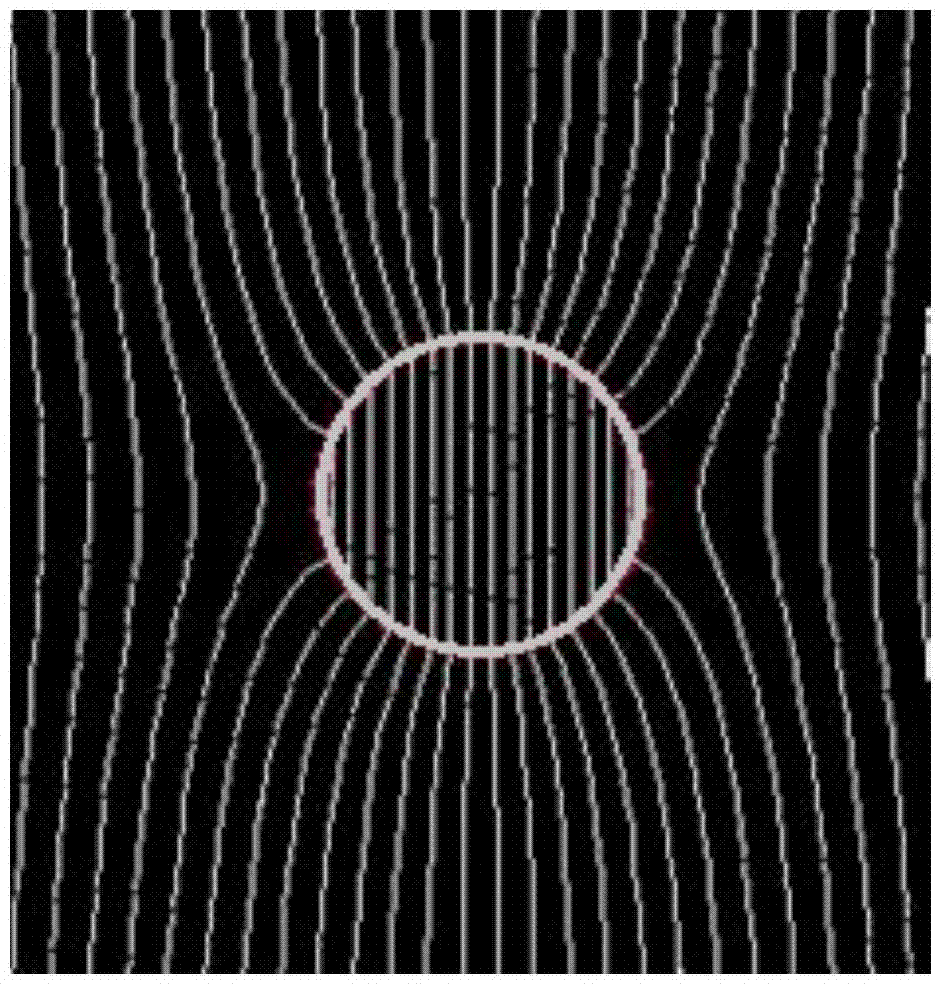

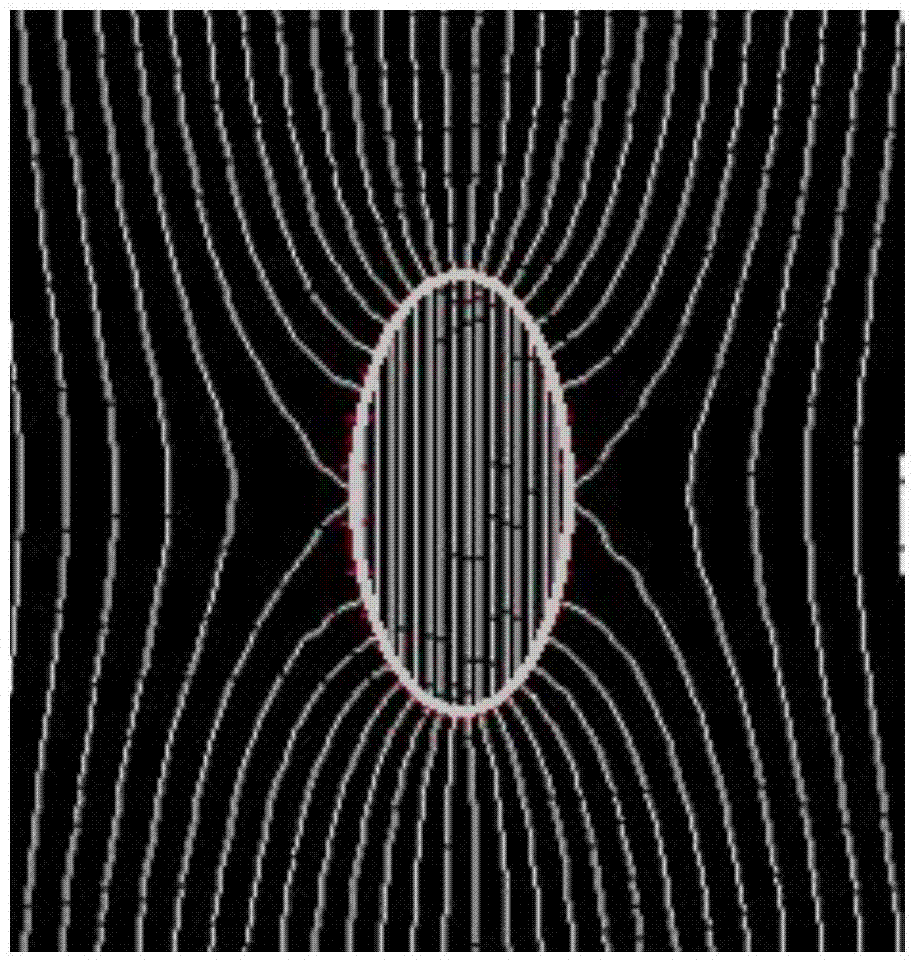

[0036] a kind of like Figure 6 The magnetism gathering medium used in the magnetic separator of the present invention is shown, the magnetism gathering medium is processed into a columnar shape, and the cross-sectional shape of the magnetism gathering medium is ellipse.

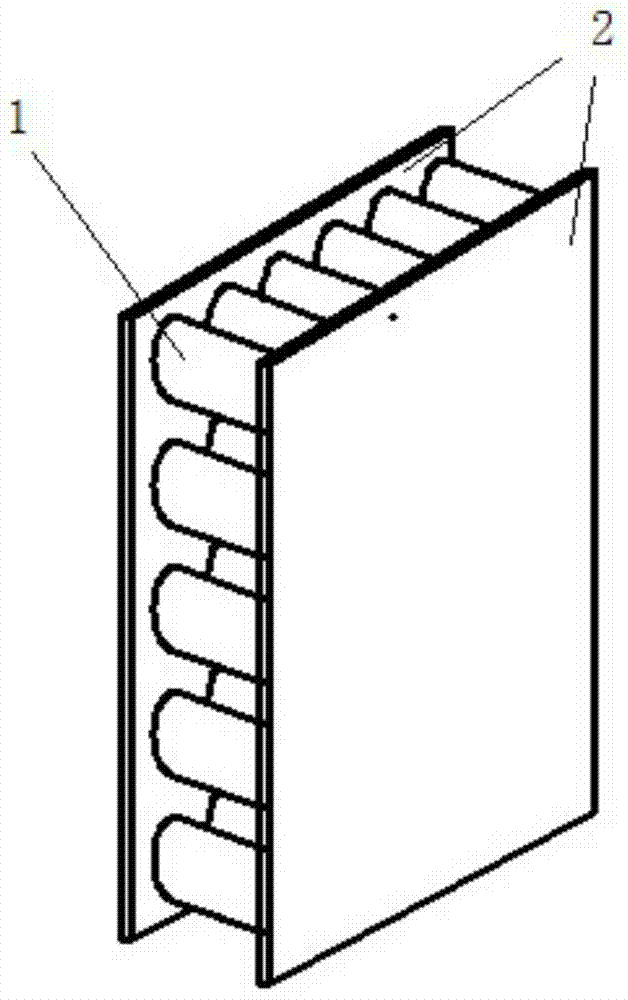

[0037] a kind of like image 3 The magnetism-gathering medium box for the magnetic separator shown in the present invention, the magnetism-gathering medium box is mainly made of the non-magnetic-conductive metal plate 2 and the magnetism-gathering medium of the above-mentioned present embodiment, the magnetism-gathering medium of the present embodiment is processed into A columnar magnetism-gathering medium rod 1 , a plurality of magnetism-gathering medium rods 1 are arranged between two non-magnetic-conductive metal plates 2 at intervals. Such as image 3As shown, the magnetism-gathering medium rods 1 of this embodiment extend along the horizontal direction, and the magnetism-gathering medium rods 1 are a...

Embodiment 2

[0040] a kind of like Figure 6 The magnetism gathering medium used in the magnetic separator of the present invention is shown, the magnetism gathering medium is processed into a columnar shape, and the cross-sectional shape of the magnetism gathering medium is ellipse.

[0041] a kind of like Figure 4 Shown is the magnetism-gathering medium box for magnetic separator of the present invention, the magnetism-gathering medium box is mainly made of the non-magnetic-conductive metal plate 2 and the magnetism-gathering medium of the above-mentioned present embodiment, the magnetism-gathering medium of the present embodiment is processed into A columnar magnetism-gathering medium rod 1 , a plurality of magnetism-gathering medium rods 1 are arranged between two non-magnetic-conductive metal plates 2 at intervals. Such as Figure 4 As shown, the magnetism-gathering medium rod 1 of the present embodiment extends along the vertical direction, and the axis of each magnetism-gathering...

Embodiment 3

[0044] a kind of like Figure 5 Shown is the magnetic gathering medium used in the magnetic separator of the present invention, the magnetic gathering medium is processed into a ring shape, and the cross-sectional shape of the magnetic gathering medium is elliptical.

[0045] a kind of like Figure 5 The magnetism gathering medium column that is used for magnetic separator of the present invention shown, this magnetism gathering medium column is mainly composed of multilayer magnetism gathering medium ring system stacked up and down (this embodiment is four layers), each layer of magnetism gathering medium The ring system is formed by a plurality of magnetic-gathering medium rings 4 concentrically set from large to small (the present embodiment is five). The magnetic medium rings 4 are spaced apart from each other by a distance, and the magnetic medium rings of each layer are spaced apart from each other by a distance. In this embodiment, the ratio of the major axis and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com