Liquid crystal aligning agent, and liquid crystal alignment film produced using same

A technology of liquid crystal aligning agent and liquid crystal aligning film, applied in coating, instrument, optics and other directions, can solve the problems of rising manufacturing cost of liquid crystal display panel, complicated and complicated plate exchange, etc., and achieve excellent linearity and dimensional stability, excellent characteristics , Excellent uniformity of film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0203] The following examples are given to further describe the present invention in detail. In addition, this invention is not limited and interpreted by these Examples.

[0204] Abbreviations of compounds used in Examples and Comparative Examples are as follows.

[0205] 1,3DMCBDE-Cl: Dimethyl 1,3-bis(chlorocarbonyl)-1,3-dimethylcyclobutane-2,4-dicarboxylate

[0206] BDA: 1,2,3,4-butanetetracarboxylic dianhydride

[0207] PMDA: pyromellitic dianhydride

[0208] DADPA: 4,4’-Diaminodiphenylamine

[0209] DBA: 3,5-diaminobenzoic acid

[0210] p-PDA: p-phenylenediamine

[0211] DA-A: the diamine of the following formula DA-A

[0212] [chem 25]

[0213]

[0214] (solvent)

[0215] NMP: N-methyl-2-pyrrolidone

[0216] GBL: gamma-butyrolactone

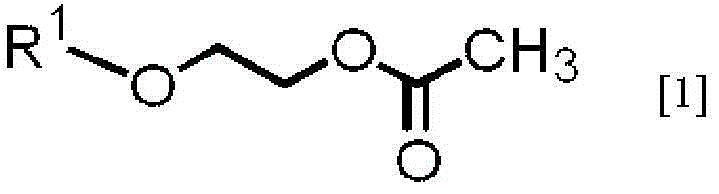

[0217] BCA: Butyl Cellosolve Acetate

[0218] BCS: Butyl Cellosolve

[0219] DPM: Dipropylene Glycol Monomethyl Ether

[0220] [viscosity]

[0221] For the viscosity of the solution of polyamic acid ester and polyamic acid, u...

Synthetic example 1

[0237] P-PDA (114.59g, 1.06mol) and DA-A (44.68g, 0.12mol) were added in a 300mL four-necked flask, NMP (1814mL), GBL (5175mL) and pyridine (210.1g, 2.66mol) were added, to dissolve. Next, stirring this solution, 1,3DMCBDE-Cl (359.85 g, 1.11 mol) was added, and it was made to react under water cooling for 4 hours. 500 mL of GBL was added and diluted to the obtained polyamic acid solution. 47300 g of IPA was poured in, stirring this solution, and the precipitated white deposit was filtered, and then, 23649 g of IPA wash|cleaned and dried 5 times, and obtained 428.0 g of white polyamic acid ester resin powders. The yield was 96%. Moreover, the molecular weight of this polyamic acid ester was Mn=15182, Mw=30115.

Synthetic example 2

[0239] Using BDA (175.94g, 0.74mol) and PMDA (52.34g, 0.20mol) as a tetracarboxylic dianhydride component, DADPA (191.28g, 0.80mol) and DBA (36.52g, 0.20mol) as a diamine component, In NMP516.9g and GBL 2068g, it was made to react at room temperature for 4 hours, and obtained the polyamic-acid solution. The molecular weight of this polyamic acid solution was Mn=15058, Mw=35072.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com