Cooling system and method of airborne heating element based on air expansion refrigeration

A heating element, expansion refrigeration technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of short launch time, high heat flux density, limited cold source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

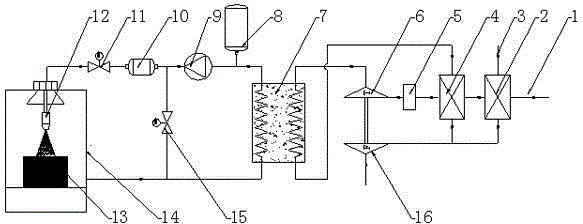

[0011] Such as figure 1 As shown, a cooling system based on air expansion refrigeration of the present invention for onboard heating elements includes an air intake 1, a primary heat exchanger 2, a ram air port 3, a secondary heat exchanger 4, and a water separator 5 , Turbine 6, cold storage 7, buffer tank 8, circulation pump 9, filter 10, flow regulating valve 11, cooling nozzle 12, heating element 13, spray chamber 14, bypass valve 15, fan 16.

[0012] The specific implementation process of the spray cooling process is as follows: the low-temperature brine is pressurized by the circulation pump 9 and then sent to the cooling nozzle 12, atomized into micron-sized droplets, and forced to spray on the surface of the heating element 13 to take away a large amount of heat. In non-boiling spray cooling, the heat transfer mechanism is mainly forced convection and liquid film evaporation, while in phase change spray cooling, nucleate boiling and secondary nucleation play a more obv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com