Coal-based anode material, preparation method and lithium-ion battery

A lithium-ion battery and anode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor processing performance, poor cycle performance, low capacity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

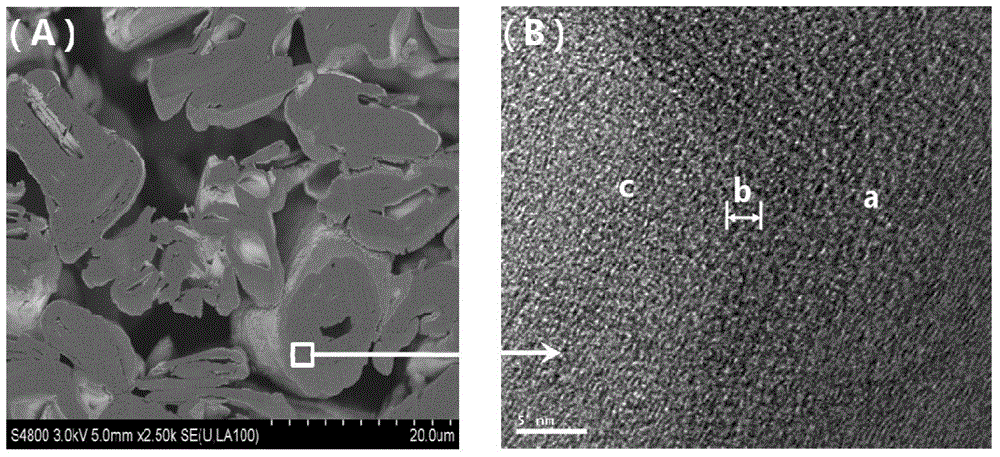

Image

Examples

Embodiment 1

[0069] (1) Anthracite with a fixed carbon content of 80.0% is pulverized to D by a milling pin pulverizer 50 =13.6μm;

[0070] (2) mixing the above powder material with 2.0% (by weight) phosphoric acid and 5.0% epoxy resin in a V-type mixer for 5 minutes, and the mixing temperature is 80°C;

[0071] (3) Put it into the inner string graphitization furnace, feed the protective gas nitrogen, and graphitize at a temperature of 2800 °C;

[0072] (4) sieving and demagnetizing the graphitized product to obtain D 50 = 15.3 μm coal-based negative electrode material, other detection indicators are shown in Table 3.

Embodiment 2

[0074] (1) Pulverize the gas coal with a fixed carbon content of 99.0% by a ball mill to D 50 = 20.0 μm;

[0075] (2) mixing the above-mentioned powder material with 10.0% polyvinyl alcohol in a conical double-screw mixer for 60min, and the mixing temperature is 25°C;

[0076] (3) Put the mixed material into the Acheson graphitization furnace, feed the protective gas nitrogen and the purified gas fluorine gas respectively, and graphitize at a temperature of 3000 °C;

[0077] (4) sieving and demagnetizing the graphitized product to obtain D 50 = 28.0 μm coal-based negative electrode material, other detection indicators are shown in Table 3.

Embodiment 3

[0079] (1) The coking coal with fixed carbon content of 95.0% is pulverized by a turbo pulverizer to D 50 =5.0μm;

[0080] (2) Mix the above-mentioned powder material with 30.0% pitch and 5.0% titanium dioxide in a conical twin-screw mixer for 60 minutes, and the mixing temperature is 120°C;

[0081] (3) Press the mixed material into a volume density of 1.0g / cm with a horizontal hydraulic press 3 put the square pressed product into the Acheson graphitization furnace, pass the purified gas chlorine gas, and graphitize it at a temperature of 3200 °C;

[0082] (4) Pulverize the graphitized cubes to D 50 = 5.8 μm, sieving and demagnetization to obtain coal-based negative electrode material, other detection indicators are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| True density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com